What is GOB Technology

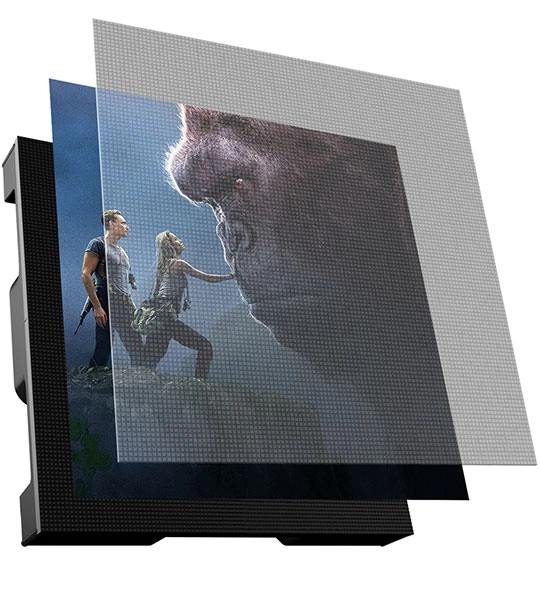

If you are looking for a high-quality, durable, and eye-friendly LED display, you might want to consider GOB technology. GOB stands for Glue On Board, and it is a new optical and thermal nano-filling material that covers the PCB board and the LED chips of a conventional LED display. It creates a matte effect on the surface of the LED display, improving its protection and enhancing its visual performance. In this blog post, we will explain what GOB technology is, how it solves the industry pain points, what are its advantages, and how it works.

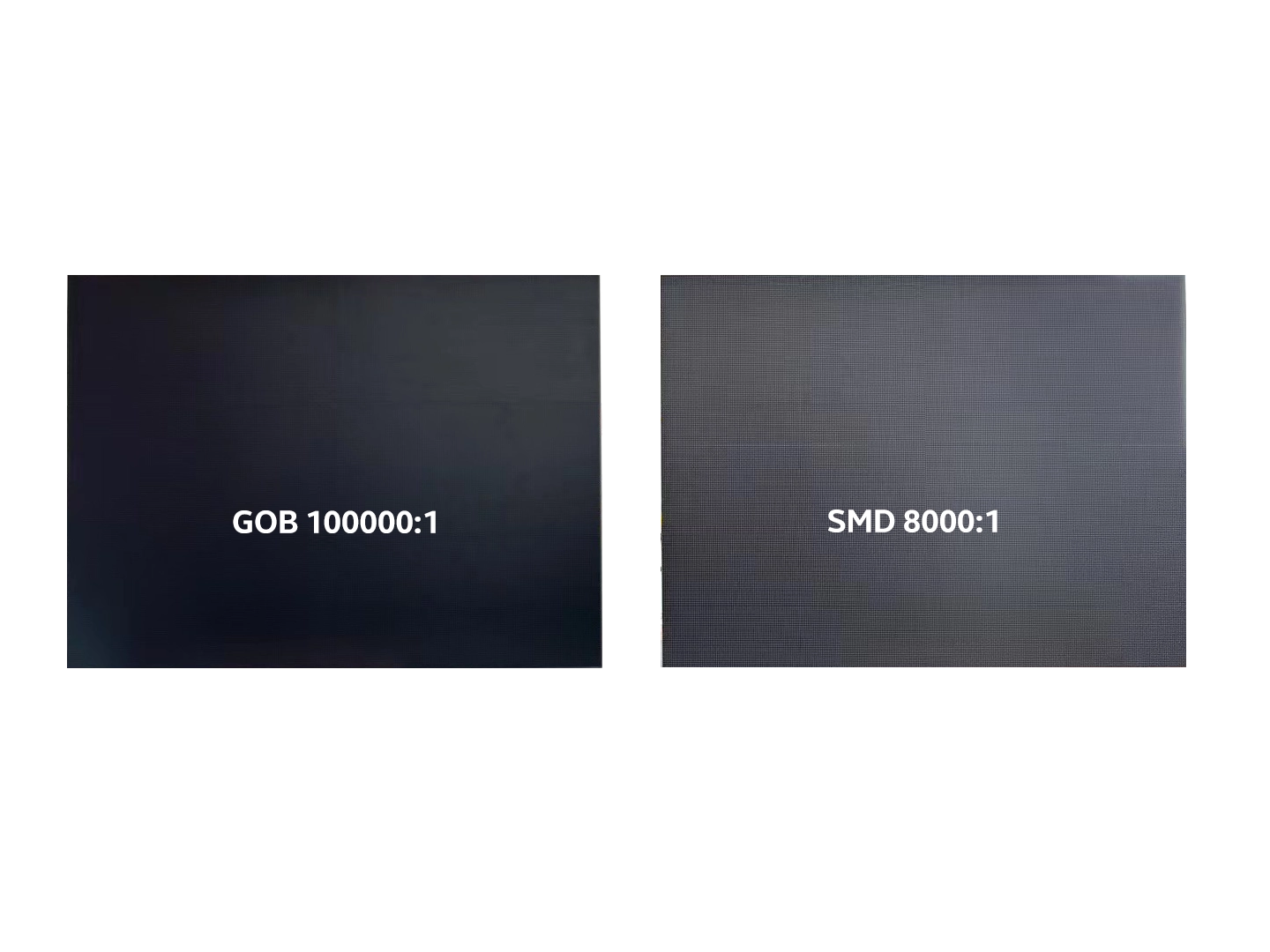

High Contrast

Eye Protection

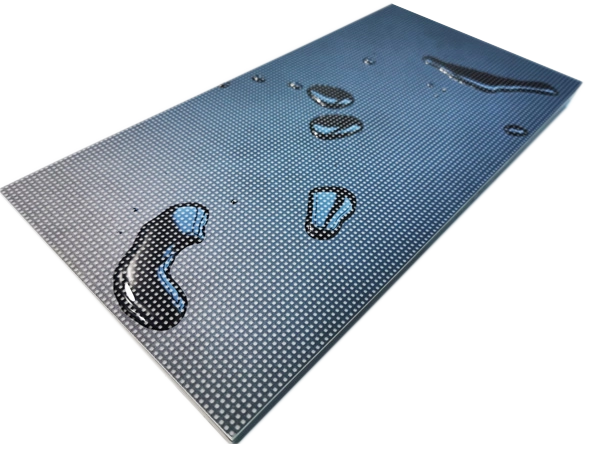

Waterproof

Fine Pixel pitch

Hassle-Free Installation.

16:9 ratio COB LED cabinet, no need to stretch the video source. Easy and efficient installation, Complete front service, Perfect design produces a uniform installation across any setting with Visionpi seamless splicing tech,eliminating gaps between frames or cabinets.

Anti-bump

GOB provides overall protection on LEDs and is widely used in rental-led displays for events and concerts.

Water & Dust Resistant

High contrast

Specialized Black Seal technology :Pristine black & color expression The fusion of an exceptionally black base with patented Optical painting material: Matte Black,Natural Black,Brilliant Black, deliver deep black levels for intense contrast and immaculate detail for for a variety of applications.

GOB Soft LED Modules

GOB Technology can be applied to flexible-led modules without affecting the flexibility.

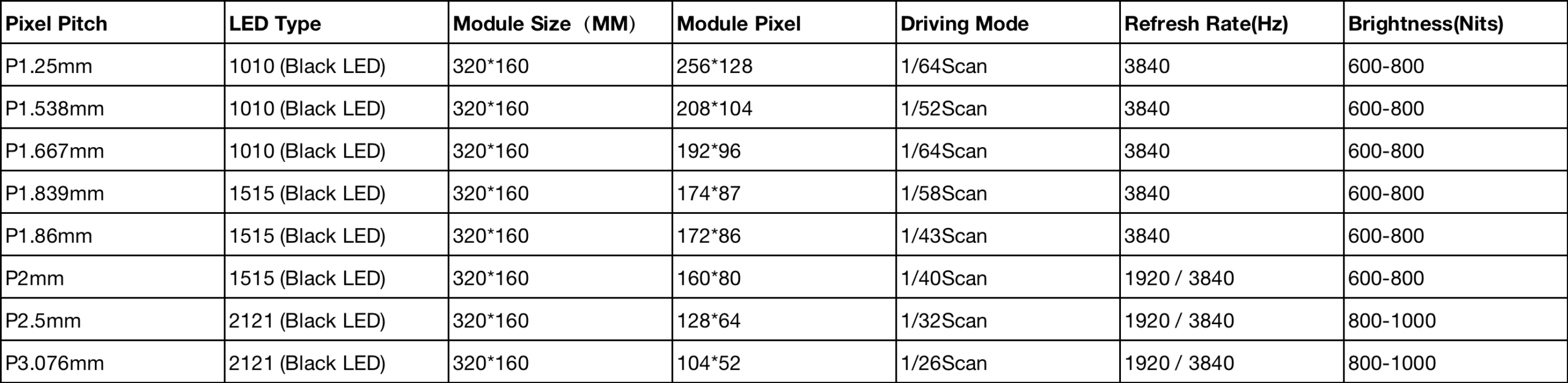

GOB LED Modules Specification 320x160mm

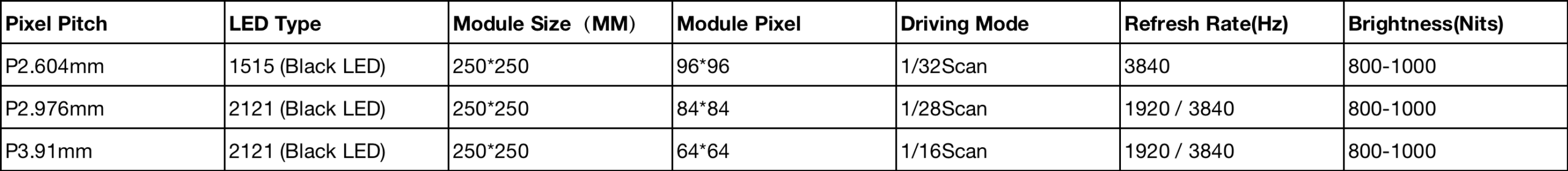

GOB LED Modules Specification :250x250mm

GOB Production Process

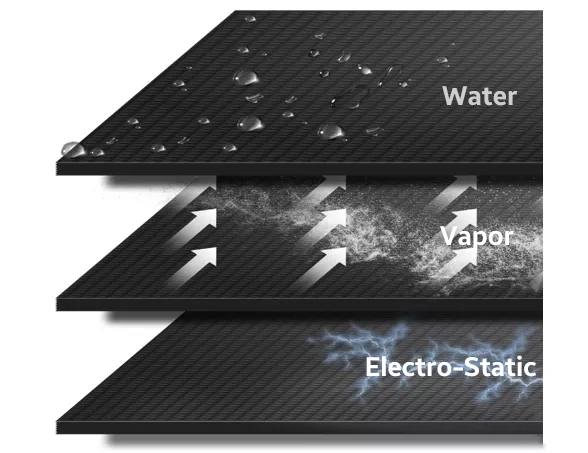

GOB technology requires a complete production process that involves reliable automated production equipment, customized A-type molds, and specially developed packaging materials that meet the product characteristics requirements. The packaging materials must have strong adhesion, tensile strength, vertical impact resistance, hardness, transparency, temperature resistance, anti-yellowing, anti-salt spray, anti-wear, anti-static, high-voltage resistance, etc.

GOB technology currently involves six levels: material level, filling level, thickness level, leveling level, surface level, and maintenance level.

(1) Cutting

The packaging material must be cut according to the size and shape of the LED display module.

(2) Filling

The packaging material must be fully filled between the LED chips and cover their surface. It must also adhere firmly to the PCB board. There should be no bubbles, pinholes, white spots, gaps, or bottom fillers on the bonding surface between the PCB and the glue.

(3) Thickness control

The thickness consistency of the glue layer (more precisely, the thickness consistency of the glue layer on the LED chip surface) must be ensured. After GOB packaging, the glue layer on the LED chip surface should be uniform. The current GOB technology has been upgraded to 4.0 version, which has almost no thickness tolerance of the glue layer. The thickness tolerance of the original module and the thickness tolerance after completing the original module are almost equal. It can even reduce the thickness tolerance of the original module. The joint flatness is perfect!

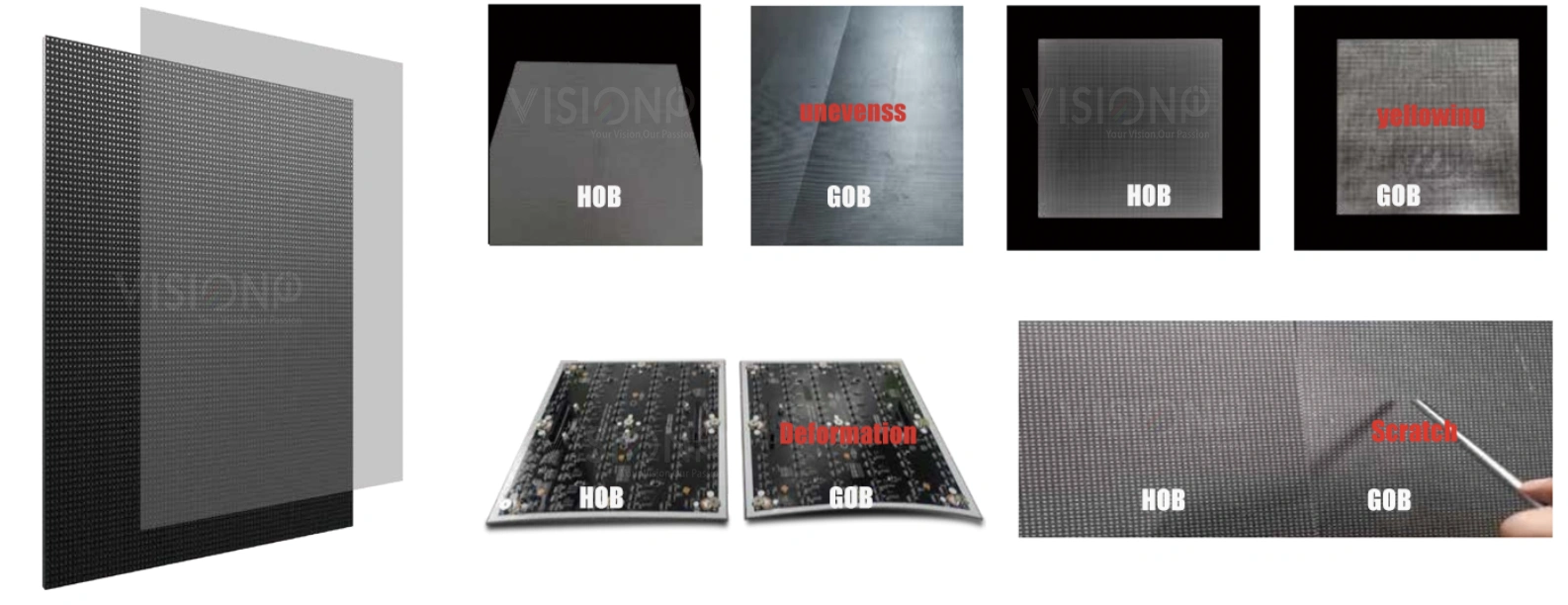

HGOB

The HGOB,also called HOB technology focuses on enhancing LED board encapsulation and film coating through several key features:

– Integrated Molding Technology: Offers exceptional mechanical strength, consistent temperature and weather resistance, preventing yellowing, cracking, and stress while being repairable.

– Thermal Shock Resistance: Capable of withstanding extreme temperature fluctuations (-40 to 85℃) for over 100 cycles without damage.

– High Scratch Resistance: Features a surface that resists scratches, achieving a scratch hardness of above 3H.

– UV and Weather Resistance: Designed to resist UV rays and weather conditions without yellowing or reflection, ensuring high consistency in appearance.

– High Maintainability: Even after repairs, the appearance remains uniform, and the lighting stays soft.

– Economical and Durable: Provides a cost-effective solution that is waterproof, moisture-proof, and anti-collision.

Get Quote for high quality led wall

We are passionate to offer you the best possible services