COB LED VS Mini LED

- II. Display Performance: In terms of display performance, the area of the Flip-Chip is smaller on the PCB board, and the duty cycle of the substrate is increased. It has a larger light-emitting area, which can present a darker black field, higher brightness, and higher contrast.COB LEDs are precisely placed on PCB boards so that the flatness and accuracy of the module are outstanding. Moreover, the viewing angle of the flip-chip COB module is around 175°, which is wider than the 160° viewing angle of the 4in1 LED module, and there is no pixel granularity on the flip-chip COB module. In addition, the flip-chip COB module can effectively suppress the moiré effect.

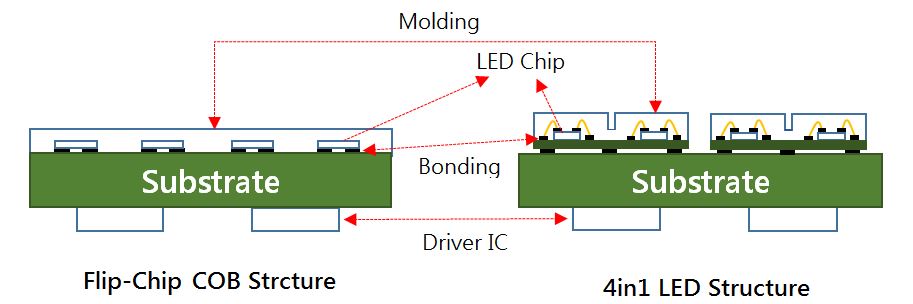

- III. Product Reliability: Flip-Chip COB can achieve true chip-level spacing, reaching the level of Micro LED. This is because, from the perspective of the LED chip, the Flip-Chip does not require wire bonding, which breaks the pixel pitch limit of the formal chip and solves the problem of metal migration in the formal LED.

LED surface of the flip-chip COB module is packaged with an integral epoxy resin mold to avoid oxidation; the exposed solder joints of the 4in1 LED module are susceptible to interference by water and oxygen.

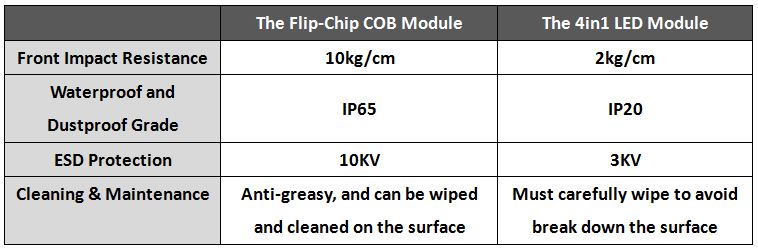

- Please refer to the following comparison table of product reliability. Comparing the various characteristics, the overall reliability of the flip-chip COB module is much better. It is more suitable for the film and TV industry that requires frequent disassembly and assembly of LED modules.

In summary, from the perspective of production cost, display performance and product reliability, the flip-chip COB module is significantly better than the 4in1 LED module. As an upgraded product of formal COB, flip-chip COB is based on the advantages of formal COB ultra-small dot pitch, high reliability, and non-glaring surface light source. Further, improve the reliability, simplify the production process, better display effect, perfect near-screen experience, and real chip-level spacing can be realized.