LED Displays are Not the Same

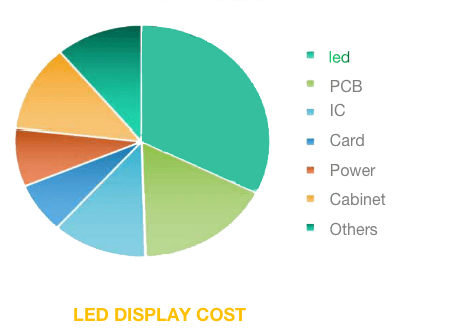

LED displays are comprised of many components. Various commercial manufacturers around the world may or may not state these components in their quotations. You may see items such as framing, power supplies, controller cards, video processors, cabling, mounting/hanging points, or display interface units either included in the bottom line or broken out as separate line items in a quotation. One word of caution before we focus on the piece of the display with the most points of differentiation. If you are comparing pricing, make sure you are aware of all the components required to make the display operational in the environment for your solution, and make sure you’re comparing apples to apples when reviewing quotations. One bottom line price may include everything you need to be operational whereas a second may be the price just for the LED panels, you don’t want to find out the fact after the order sealed, at the end you are paying more.

LED Diode

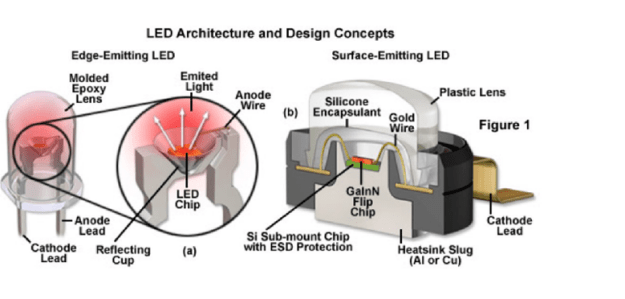

The core of led display LEDs are diodes – meaning they are semiconductors. They are the most important unit for a led display and takes on 50-60% of the total cost. The two main types of LEDs presently used for lighting and display systems are aluminum gallium indium phosphide (AlGaInP, sometimes rearranged as AlInGaP) alloys for red, orange, and yellow LEDs; and indium gallium nitride (InGaN) alloys for green, blue and white LEDs. Slight changes in the composition of these alloys change the color of the emitted light. The actual chips/dice/wafers of the (LED) manufacturing process are basically the same the world over. What makes one manufacturer’s diode better than another is basically the consistency of the manufacturing process, the predictable, repeatable processes rendering consistent yields. This is accomplished by rigid manufacturing standards, “Six Sigma” processes, purity of chemical elements, etc. Diode manufacturers in the industry gain a reputation for delivering consistent and reliable quality. If you’ve been in this industry for a minute or two, you know the names that always come up when discussing quality. One starts with an “N” and one starts with a “C”. That being said, there are other contract manufacturing companies whose process is being guided and refined by the display manufacturers, which are turning out diodes of comparable quality.

Just as with any consumer or commercial goods we buy, the reason some products cost more than others owes to labor and shipping costs, and the quality of the materials used. There are cheap TVs at Walmart, and premium TVs at Best Buy. They do the same thing, but what’s inside the housing can be different. On a direct-light LED circuit board, is a grid of attached pixels – or the smallest addressable components on the display from the perspective of content delivery. These “pixels” typically are what is referred to in the industry as a “package” and as you might expect, given the name, these are comprised of several individual elements – all of which can be differentiators in the performance and efficiency of the display. The quality and type of wiring used, the circuit board backplates, the epoxies, and numerous other things affect the final price of display electronics, as well as performance and reliability.

The actual chips/dice/wafers of the (LED) manufacturing process is basically the same the world over. What makes one manufacturer’s diode better than another is basically the consistency of the manufacturing process, the predictable, repeatable processes rendering consistent yields. This is accomplished by rigid manufacturing standards, “Six Sigma” processes, purity of chemical elements, etc. Diode manufacturers in the industry gain a reputation for delivering consistent and reliable quality. If you’ve been in this industry for a minute or two, you know the names that always come up when discussing quality. like Nichia and Cree. There are other contract manufacturing companies whose process is being guided and refined by the display manufacturers, which are turning out diodes of comparable quality. Pay attention to the spec of the LEDs, even for those LEDs comes from the same vendor, they have different level quality, it mainly depends on the material and technology that made of LED: Wire bonding, Reflector, Glue.

Package Design

Package Quality

The actual chips/dice/wafers of the (LED) manufacturing process is basically the same the world over. What makes one manufacturer’s diode better than another is basically the consistency of the manufacturing process, the predictable, repeatable processes rendering consistent yields. This is accomplished by rigid manufacturing standards, “Six Sigma” processes, purity of chemical elements, etc. Diode manufacturers in the industry gain a reputation for delivering consistent and reliable quality. If you’ve been in this industry for a minute or two, you know the names that always come up when discussing quality. like Nichia and Cree. There are other contract manufacturing companies whose process is being guided and refined by the display manufacturers, which are turning out diodes of comparable quality. Pay attention to the spec of the LEDs, even for those LEDs comes from the same vendor, they have different level quality, it mainly depends on the material and technology that made of LED: Wire bonding, Reflector, Glue.

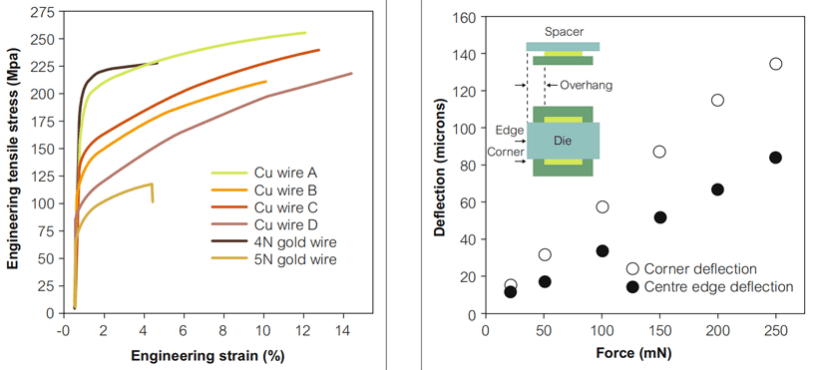

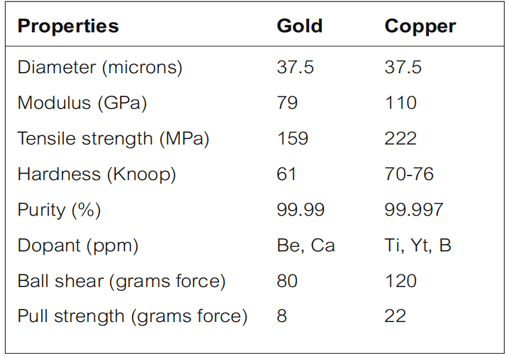

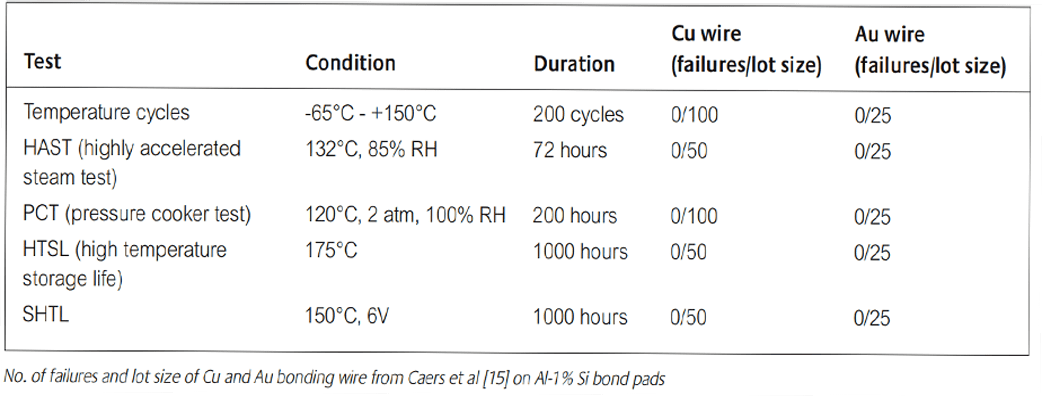

Bond Wire

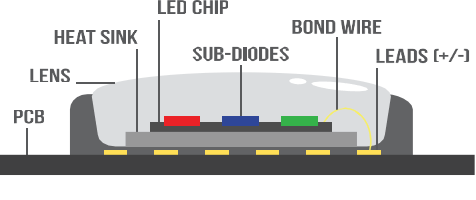

Gold, copper, Iron The conductor and wire bonding in the package is the apparatus which, as you might suspect, transfers electric current from the circuit board to the diodes. Conductors are located on the underneath or backside of the package carrier and consist of an anode and cathode division (positively and negatively charged). These pieces are manufactured from one of three different metals – gold, zinc, or silver. The lining within the diode’s package cavity on the front of the package is referred to as the reflector. This comes in variations of two colors – either black or white. As you might suspect, white or whiter colors of reflectors better reflect, and more efficiently channel, the light from the diode outward away from the package. Black or darker reflectors tend to absorb more of the light from the diodes. The actual shape of the reflector cavity has much to do with the quality of the image and brightness. learn more about wiring bonding material.

Reflector

This will be discussed further when we discuss fill ratios. While we’re discussing the coloration of the reflector, it is also a good time to talk about the face of the package itself. These also come in various gradients of white and black and serve a similar function as the reflector. As a general rule of thumb, both of these elements either serve to enhance brightness (whiter elements) or to enhance contrast (blacker elements). Black face LED packages typically are better when the preferred result is for greater image detail. White and lighter face LED packages are preferred when brightness is a key requirement for content delivery – such as combating hostile ambient light conditions. Package faces also come in different finishes, matte finishes, glossy, and variations in between. We’ve talked about all of the components of major differentiation within the LED package sans one.

Len

The lens. The lens of the package is comprised of an optically translucent sealer material – most commonly silicon – which fills the cavity housing the diodes. The lens composition, as you might guess, affects to a greater or lesser extent, the optical performance of the package. Counterintuitively, a certain amount of opacity within the lens material actually enhances overall image quality for the average human viewer with 20/20 vision.