IC Costs:

Classic Constant Current Chip is not designed specifically for LED, but some logic chips with an LED display portion of logic functions The chip is in accordance with special LED light emission characteristics designed specifically for the LED display driver chip. LED is a current characteristic of the device, that is, under the premise of saturated conduction, the brightness varies with the change of the current, rather than by adjusting the voltage across it varies. Therefore, one of the largest dedicated chip features is to provide a constant current source.

The constant current source can guarantee the stability of the LED drive, eliminating flicker LED, LED display is a high-quality picture premise. Functional chip: Some dedicated chips for the requirements of different industries also added some special features, such as LED error detection, and current gain control current correction.

LED display performance indicators, an image refresh rate, and gradation expression are the most important indicators. This requires that LED display driver IC inter-channel current have high consistency, high-speed communication interface rate, and constant speed of response. In the past, refresh rate, and gray-scale utilization of three is a shift in the relationship, to ensure that one or two of the indicators which can be more excellent, would have been appropriate to sacrifice the remaining two indicators. For this reason, many LED display is difficult to practice both ways, either refresh is not enough, the high-speed camera equipment shoots prone black lines, or is not enough gray, and color brightness and darkness are inconsistent. With advances in technology driving IC manufacturers, now a breakthrough in the problem of three highs has been able to solve these problems. In the application of LED full-color display, in order to ensure user comfort for a long time with the eyes, low-light high ash becomes a test driver IC performance a particularly important standard.

The drive IC trends

1) Energy Saving.

As a green energy-saving LED display is an eternal pursuit, it is also considered an important criterion driver of IC performance. Saving driving IC includes two aspects, one is to reduce the knee voltage constant current, and thus the traditional 5V to 3.8V power supply to reduce the following; the second is through the optimization algorithm and IC driver IC design reduces the operating voltage and operating current. There are already manufacturers launching a 0.2V low voltage transition, improvements of up to 15% utilization of LED constant current driver IC, using 16 percent conversational products to reduce heat supply voltage, which greatly enhances the energy efficiency of the LED display.

2) Integrated.

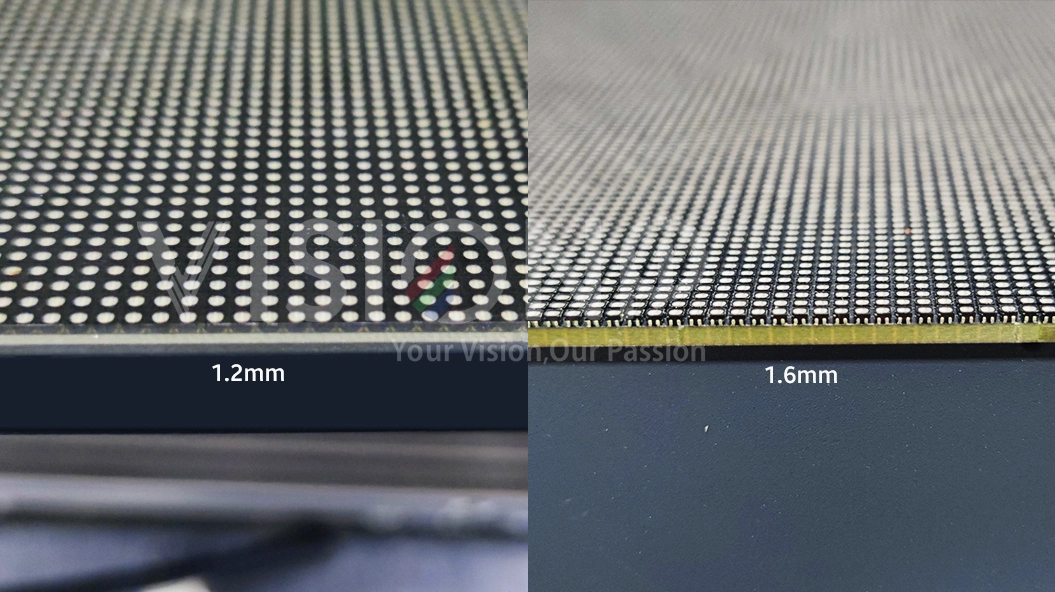

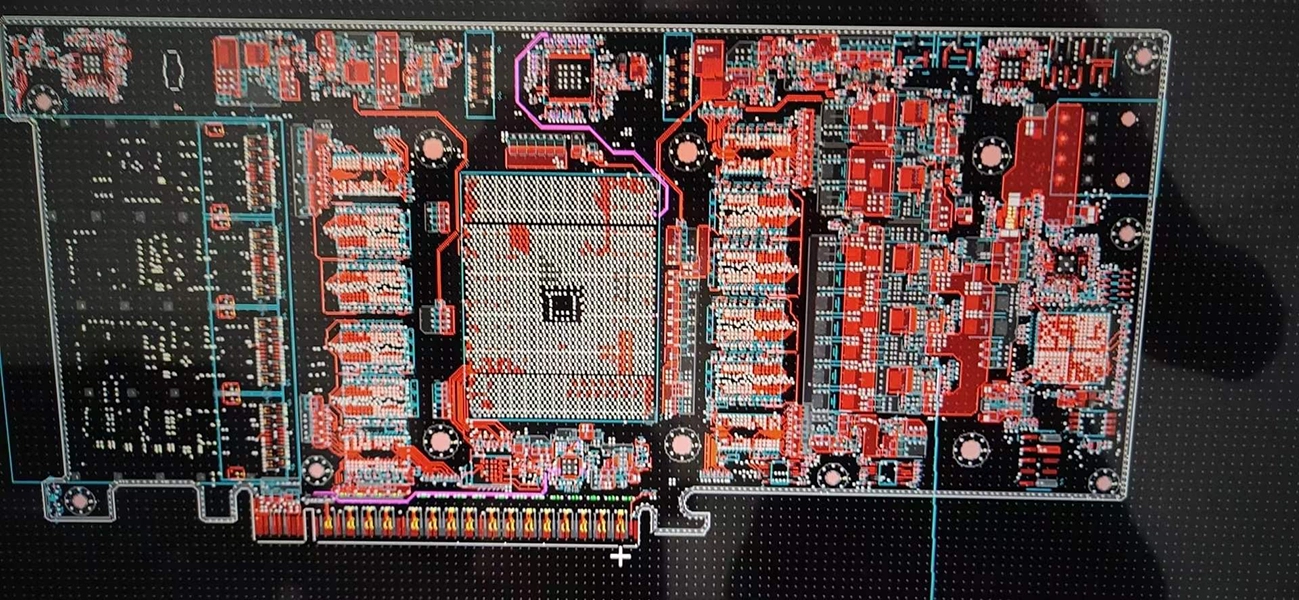

With the rapid decline of the pixel pitch LED display on the unit area to mount packaged devices to grow exponentially, greatly increasing component density module drive surface. In a small pitch P1.9 LED, for example, 15 sweep 160 * 180 90 module requires constant current driver IC, 45 tube rows, 2 138. So many devices available to make PCB routing space become extremely congested, increasing the difficulty of circuit design. At the same time, so crowded arrangement of components can easily result in poor welding and other issues but also reduces the reliability of the module. Driver IC less the amount, the greater the PCB layout area, and demand from the application side of the driver IC must be Forced onto the highly integrated technology road map. And Rui Ling photoelectric RS1.9 small pitch LED display, is the case of so many devices make improvements, to ensure the reliability and stability RS1.9 the same circumstances, the use of highly integrated 48-channel constant current LED driver IC, the large-scale integrated circuit peripheral to the driver IC crystal cell, reducing the complexity of the application side of PCB board design, the constant current driver IC 180 reduced by nearly three times, constant current driver IC becomes 48. 45 sweep 152 * 171mm module requires only 48 constant current driver IC, 30 column pipe, line pipe 16, and two 245 signals. After developing and testing, we found even better results than the previous 180 constant current driver IC effect, but also play a role in energy conservation.

LED Display Driving IC brands

IC: MBI, Chipone, Silan, Toshiba, TI, SM Micro ( MBI and Chipone are very common in the market) Power supply: Delta; Greatwall, Meanwell, G-Energy, Chuanglian, Rong Electric, etc. ) Delta and Great wall are the best, Meanwell is well known in led display applications; G-energy is widely used by many factories, and Chuanglian Rong is at the same level.

MICROBLOCK: As the leading supplier of LED display driver ICs, our products have been chosen and applied to various world-class events, landmarks, as well as venues with specific demands and strict requirements such as control rooms. there are some recommended options for Different Applications:

CHIPONE was founded in 2008, Beijing. and grew up to be one of the leading led display drive IC companies in the industry,3 million pieces of LED display driver lit a large screen of the Tiananmen parade. The development of the Company is based on three aspects: cost-driven, technology-driven, and diversified product portfolio driven. Cost-driven means reducing the cost and improving product stability through the scale effect. CHIPONE has been a good alternative for MBI.more and more led display manufacturers are introducing chip one in their products. Chipone is one of the favorite brands, in recent years, especially for those led module manufacturers, here are some of the classic ICs: Basic: ICN2037.ICN2038.ICN2038S:1920HZ