- Level 1: the recently-created and unstructured workshop; and the factories only make the assembly work with all the half-completed product purchased from other suppliers, there are thousands of factories like this.

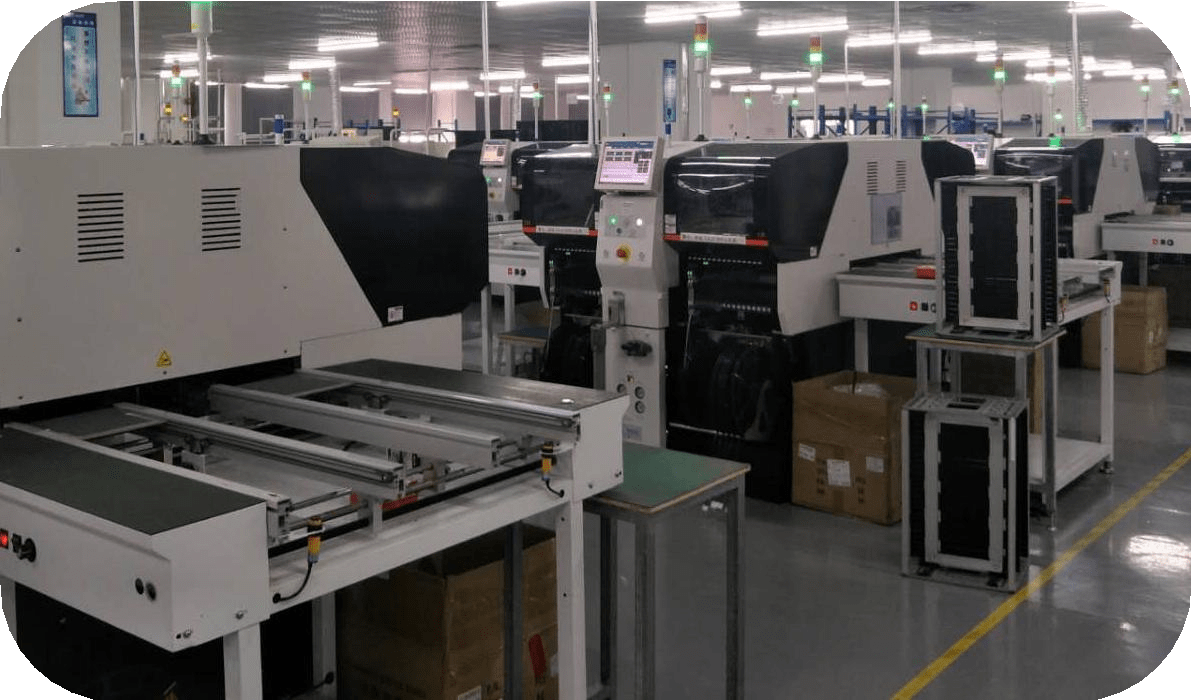

- Level 2: the semi-organized factory that got out of level 1 but is still struggling to keep quality & timing under control, they have SMT machines, they can produce led panels themself, and focus on the segmented market, like led poster, rental display, transparent.

- Level 3: the factory that made big efforts to get organized, with the objective of pleasing large customers, and they usually with many years of experience and their own R&D team and overseas sales team. here we can name a few, chip show, GCL, SBC.Yestech.

- Level 4: that rare birds like Yaham, Unilumin that applies Lean manufacturing, and that avoids level 3’s rigidity.

In this article, I am excluding Chinese state-owned enterprises, which are a breed on their own.

Most manufacturers are at level 1 or level 2:

Level 1: the unstructured led display workshop

Typical profile:

- 0-50 workers, engaged in simple processing (often assembly);

- Managed by the owner and his family;

- Not mature quality system and quality control staff;

- No ability or time to work on complex prototypes before production starts;

- Focused only on “making production” fast and on the cheap;

- Can accept small orders, as long as purchasing components in small quantity is possible;

- Seldom works directly for export customers;

- Count on other manufacturers or trading companies to get business.

Result: low costs and low MOQs, but needs to be followed very closely by customers.

Level 2: the semi-organized led display manufacturer

This category is a mixed bag. Some export 100% of their output and are very familiar with their market’s quality & safety standards. Others focus more on the domestic market or the most price-sensitive countries (Middle East, India…), and should be avoided by importers from North America and Europe.

Still, it is possible to draw a somewhat typical profile:

- 50-100 workers

- Has grown out of the “disorganized workshop” stage

- Has had to hire a few professional managers because of the growing complexity of operations

- Has had to hire a few QC employees, to avoid big disasters.

- But still, low concern for quality among staff and managers (in most cases).

- May have English-speaking salespeople if direct relationships with foreign customers is a goal.

- May still get orders mostly from trading companies and other factories.

Result: costs are relatively low, and quality & timing are relatively unstable. The owner’s motivation for your orders still determines their reliability.

Level 3: the organized/Listed led screen manufacturer

Typical profile: 200+ workers, usually established before 2010 with decade experience.

They have tried hard to comply with demanding buyers’ requirements:

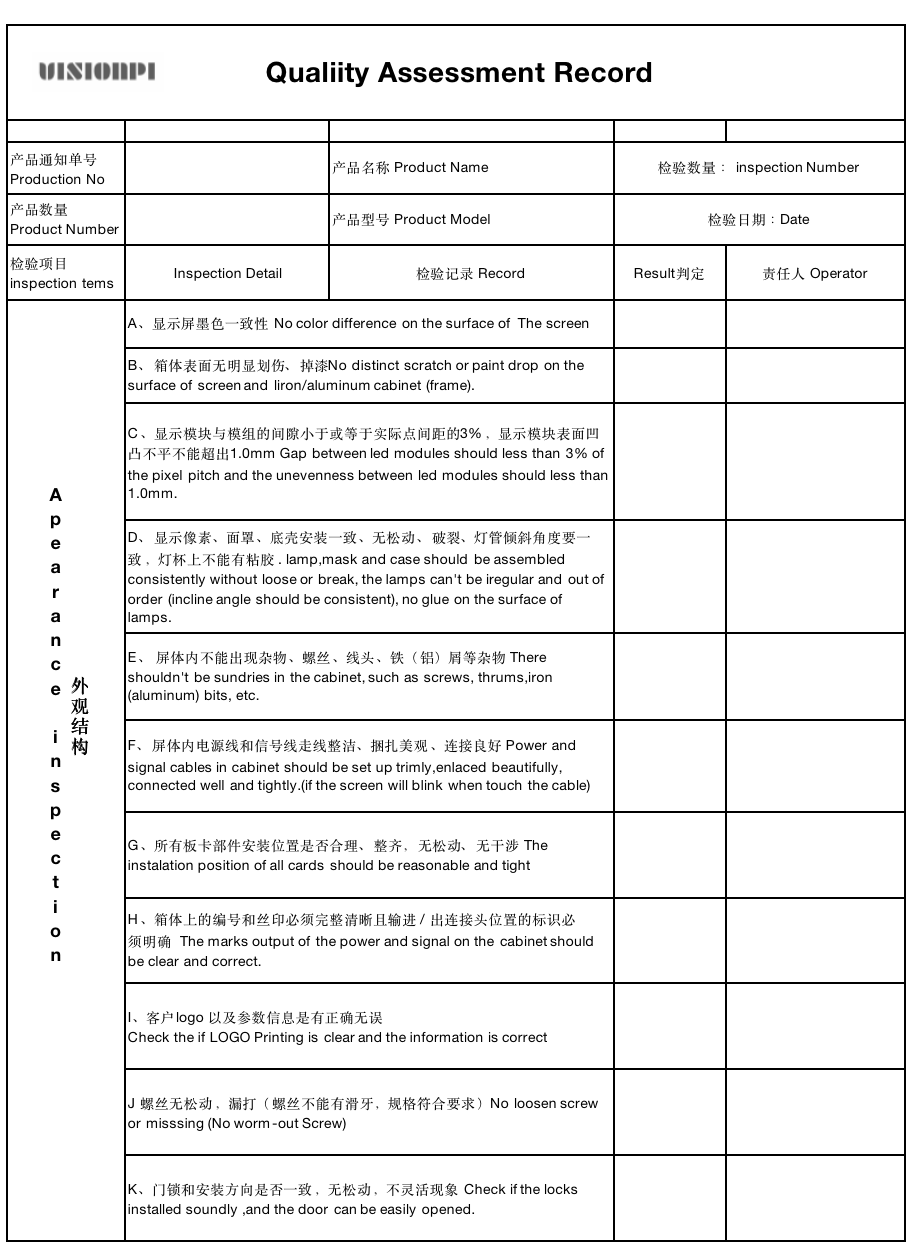

- Every aspect of production is specified in detail;

- Production is checked thoroughly by QC department;

- Own R&D team and updating led

- Hopefully, strong staff discipline to follow the system;

- a team for export business,and 60-80% of their sales is come from exporting.

Result: few quality issues, but high indirect labor costs (QC, middle management) and low flexibility. Top 10 led sign board manufacturers

Level 4: the continuously improving led display manufacturer

Typical profiles:

- Part of a large multinational group or a joint venture.

- Midsize factory with a process-oriented/engineering-oriented general manager.

- dedicated to segment markets, like transparent led display or soft led display.

They follow the lean model:

- Regular improvements to material flow and to each process;

- Errors are prevented or corrected at the source;

- Staff is trained and supports the philosophy.

Result: high customer satisfaction (close to zero defects; production cycle below 5 days) and relatively low cost (high productivity of operators, limited QC staff, and rework).

Unfortunately, these companies are a very small minority. They usually don’t advertise themselves on B2B directories. They are very hard to find.