We are discussing why a pre-production sample is so important for obtaining your desired results once your products go into mass production.

What are PP samples? How do they evolve over time until they’re a final ‘golden’ pre-production sample? What problems do they help avoid? How to specify your exact requirements? Who pays for them? These questions and more are answered in this episode!

What are pre-production samples and where do they fit in the production process? – a pre-production sample can be any sample that is put together before mass production starts, especially for a customized led display that has never been produced before. usually for a specific environment, like sea area, mountains, desert, etc., or special share design screen, whereas others are a final PP sample (golden sample) which demonstrates what the mass-produced products should be like.

- Electromechanical products- LED DISPLAYS – There are a number of key parameters to be decided for the led panels during the first article configuration: the wavelength, color temperature, brightness, power, and grey level. If the buyer confirms that the prototype looks and functions how they like it becomes an approved prototype or sample. The point is that in different industries there are different PP samples made during the pre-production process and they serve different purposes, helping to validate different features of the product stage by stage. But there will be a final PP sample which is what you expect to receive from mass-production runs.

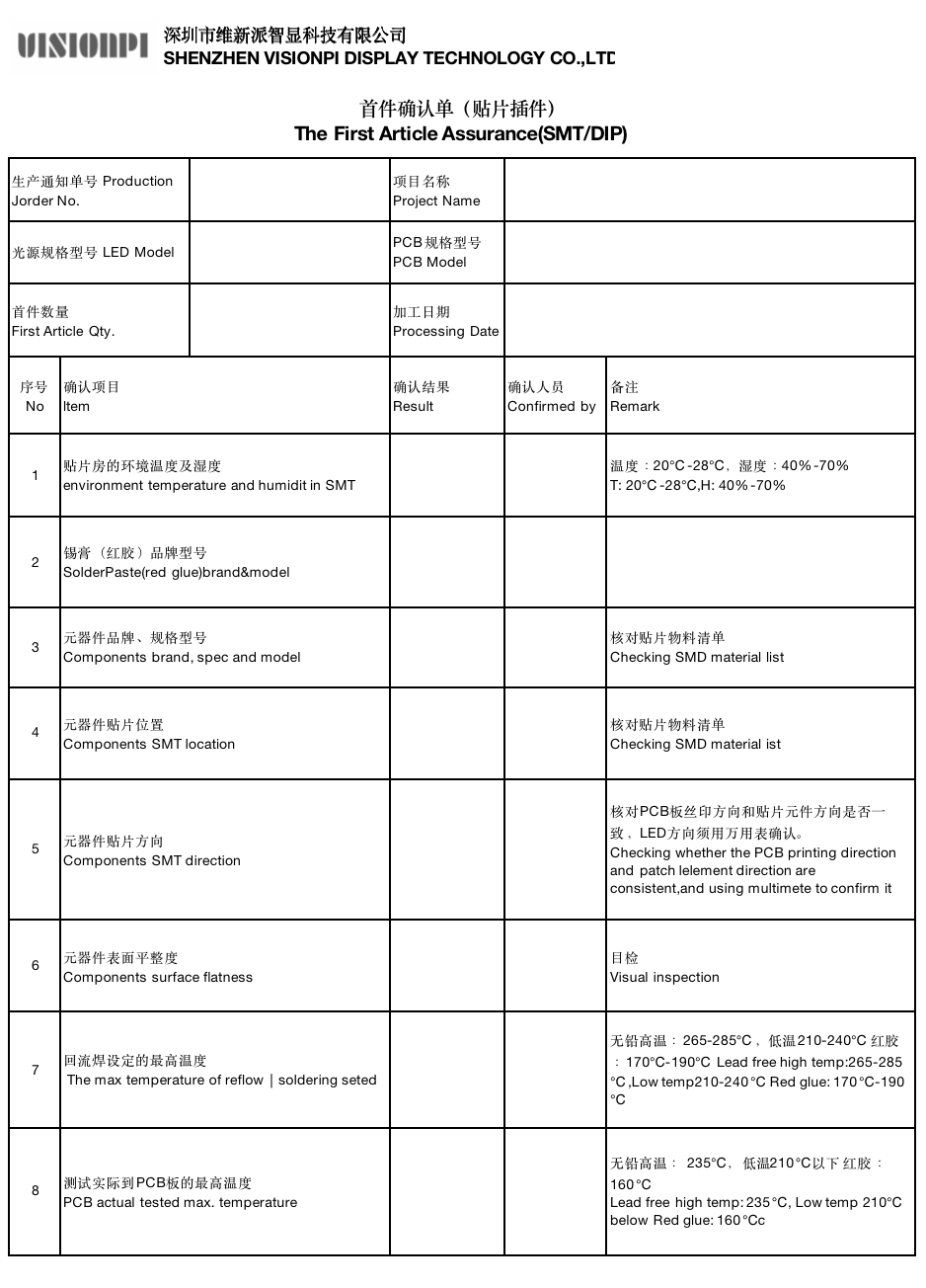

✅ About ‘First article’ samples – these are the final PP samples that should be emulated in production. Manufacturers should keep a few of these, identify them clearly, and keep them safe and clean. Typically one should be kept for the quality staff, at least one for the production staff, and one for R&D staff, too. This helps the factory stay on track.

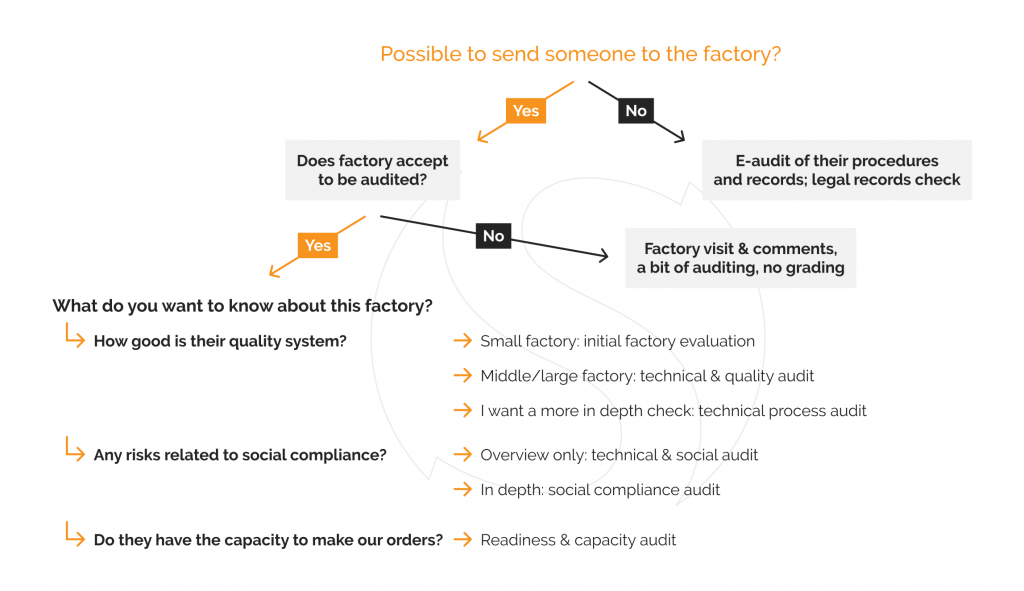

✅ How do you assure that your external inspection company gets hold of the PP sample? – A couple of ways to do this.

- If you trust your supplier the inspector can use their PP sample as your ‘approved sample’ as long as you are sure that your factory will not play any games. This cuts costs and simplifies the process, but it’s open to abuse if someone in the factory gives them a PP sample that has been tampered with (perhaps to suit their needs, such as being able to use a cheaper material, etc).

- Send the inspection company a sample – easiest is to send it to your supplier’s factory in a sealed package which is only to be opened by the inspector once they arrive (again, if trust is an issue this could carry risks), or you can send it to the inspection company’s office, but you need to be sure that the inspector can actually get the sample before they carry out your inspection and, in some cases, it may be that the inspector is rarely in the office and could live in a completely different region. If so, allowing time for it to be shipped to them internally is necessary.

✅ Some issues that we can expect to iron out during pre-production sample development – There are a number of ways obtaining PP samples can help avoid issues that would cause trouble if they were to make it into production pieces. For example:

- The buyer may receive a PP sample from their supplier and notice that they really haven’t understood their needs well at all, such as using the wrong color. PP samples help to tangibly clarify understanding far better than a collection of photos, emails, and WeChat messages.

- They should be tested according to the QC checklist and testing plan – if you have a final PP sample that is identical to what should come off the line during mass production, it’s a good opportunity to conduct testing and assure the product’s compliance with your standard and market’s safety requirements, etc, before production starts.

✅ Is it common for the PP sample process to be skipped? – buyers should know that they need a PP sample in their hand, although for large items like furniture or machinery this may not be possible.

✅ Why do suppliers deviate from your PP sample during production and what can be done to guard against this happening? – some buyers work with a supplier after seeing a sample that seems great and ‘shaking hands’ on what will then be produced. However, they have not clearly defined their specifications and quality standard in black and white, therefore, if finished products are made with some defects or non-compliances the manufacturer may effectively say something like: “But you didn’t specify this precisely…” There will possibly variations between colors, positioning of a logo, etc, so a standard needs to made stating explicitly what is and isn’t acceptable (for example, stating that ‘this shade of blue is perfect and I can also accept this slightly darker shade, but anything darker than that is not acceptable).

To make your standard crystal clear, a well-defined QC checklist needs to be made and provided to them so there can be no gray areas or assumptions.

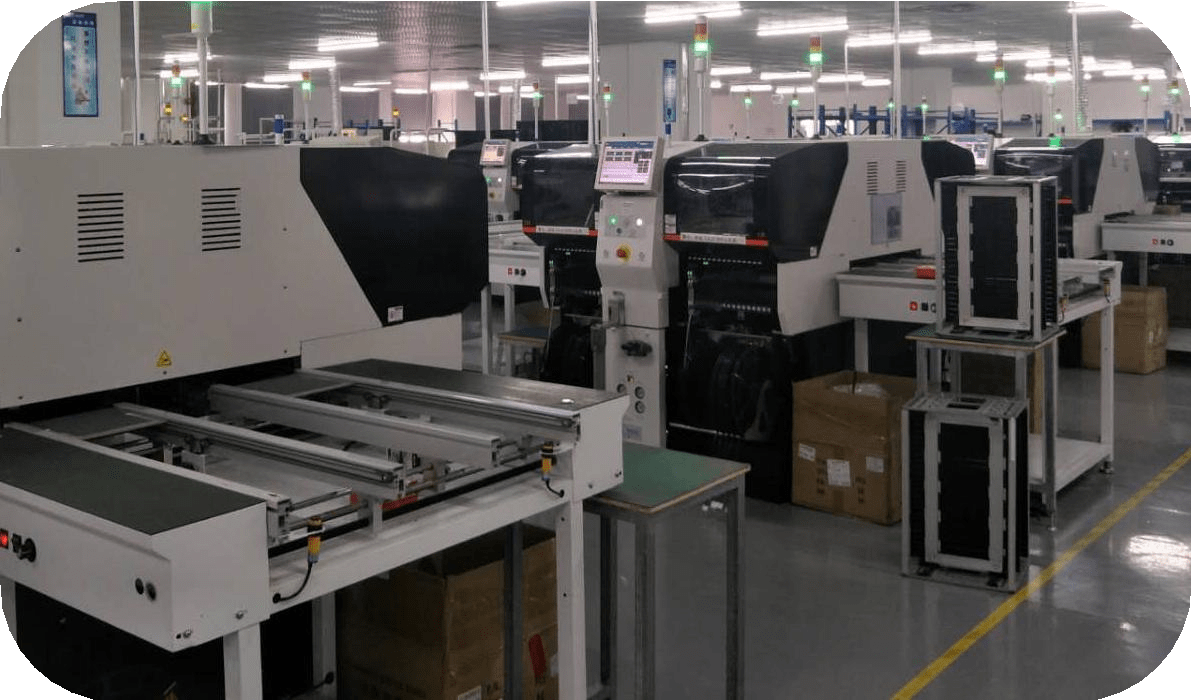

✅ How to reduce variations? – assure that your supplier’s sub-suppliers provide high-quality parts and materials. They need to do preventive maintenance on their equipment, train, and provide good work instructions to their staff. The storage of materials appropriately, such as reducing humidity for batteries, also has an impact on the final quality of the product. Success here is connected to vetting the supplier.