LED Display Hanging System

Visionpi provides a comprehensive selection of professional stacking and hanging systems designed to securely mount your LED panels. It’s important to recognize that hanging or stacking your LED display introduces additional considerations to the setup process. To ensure the safety and stability of your LED wall, we strongly recommend adhering closely to the guidelines provided in our manuals. We also offer useful tools, such as a ballast calculator, to assist in making safe installations. If you are unsure or need further assistance, please consult a qualified rigger or structural engineer for precise calculations, or contact our Tech Support team for support. All our hanging and stacking materials meet the relevant standards and regulations.

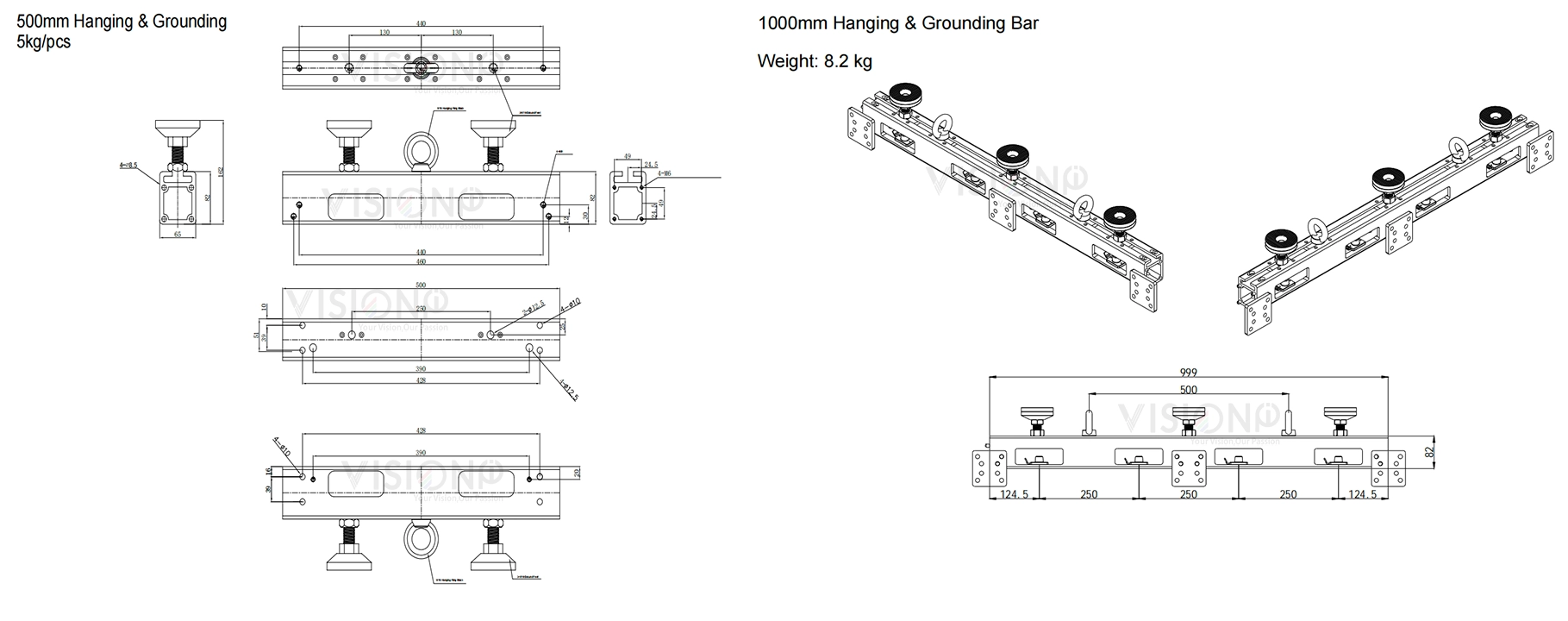

LED Screen Ground bar

LED Screen Hanging bar

Ground & Hanging bar

Characteristics of the 0.5m Hanging Bar for LED Screens

The 0.5m Hanging Bar is an essential accessory for installing LED screens. It is made from a durable, high-performance iron alloy and measures 50 centimeters in length. The hooks, crafted from aeronautical aluminum, ensure a sturdy and solid connection.

Advantages of Using the 0.5m Hanging Bar for LED Screens

– Even Weight Distribution: The hanging bar spreads the weight of the screen uniformly, reducing strain on any single point.

– Level Alignment: It assists in maintaining a consistent alignment among panels, ensuring a seamless display.

– Safety and Economy: This is the safest and most cost-effective method for mounting LED screens, preventing damage over short, medium, and long terms.

– Extended Screen Lifespan: Using the hanging bar can prolong the operational life of your LED screen.

– Professional Appearance: It enhances the overall look of your setup, contributing to a more polished and professional presentation.

LED Display Ground Bar

Using a ground bar to install an LED display provides several key benefits:

- Stability on Uneven Surfaces: It ensures the display is stable and level, even on uneven ground.

- Uniform Alignment: Helps maintain a seamless visual display by keeping all panels aligned at the base.

- Structural Integrity: Distributes weight evenly across the base, reducing stress on panels and connectors and extending the lifespan of the display.

- Simplified Installation: Makes setup and maintenance easier by providing clear guidelines for positioning panels.

- Safety: Enhances safety by securing the display, reducing the risk of accidents in public spaces and events.

Haning Bar and Ground Bar (2 in 1)

Our innovative 2-in-1 grounding and hanging bar integrates both hanging and ground stacking functionalities into a single unit, streamlining the installation process for LED displays. This dual-purpose design not only saves installation time but also reduces costs by eliminating the need for separate accessories. The integrated system enhances setup efficiency and simplifies logistics, making it an ideal choice for various event types and permanent installations. Explore more to discover how this versatile solution can meet your specific display needs, offering both flexibility and reliability in one compact package.

LED Display Stacking System

The ground stacking system simplifies the process of stacking LED screens on the ground. This modular setup features a robust steel base linked with a 29 cm ladder truss and a versatile multiconnection plate, which is compatible with any LED screen. Stability is ensured with two adjustable feet at the front and one at the back of the base, all fine-tuned to achieve perfect balance with the aid of an integrated bubble level. The system’s flexibility is a key benefit, allowing it to accommodate various LED screen sizes and configurations by adjusting for different heights and widths.

Furthermore, the connection between the ladder truss and the LED screen is facilitated by an arm featuring a side clamp. This clamp connects to the multiconnection plate via an exclusive 40 mm side extensible aluminum tube, enhancing the system’s adaptability and ease of use.