LED Display Wavelength Selection

LED Binning of LED Display

LED binning is a complex process that ensures consistent performance and quality across LED Displays. It is employed to address the variations that occur during the industrial production of LEDs, even within the same product batch.

Why LED Binning/ Batch match is important .

Improper binning can have several consequences when it comes to LED displays..If a display manufacturer were to indiscriminately purchase a run of packaged diodes from a diode manufacturer without any thought to the variation of optical and electrical specifications between the diodes, the display product they eventually manufactured would exhibit inconsistent performance.

Every display will exhibit small inconsistencies over time, but negligent binning will exacerbate the issues stemming from these inconsistencies, necessitating repeated calibration.

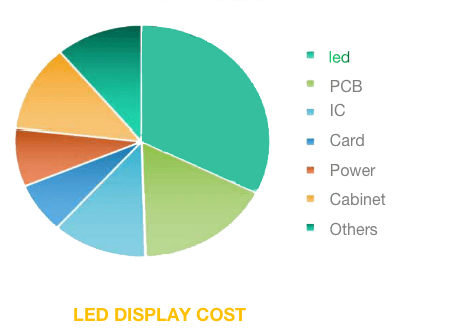

The process involves grouping LEDs with similar performance together in “bins” based on factors such as lumens, color temperature, voltage, and color.

Why the LEDs are different?

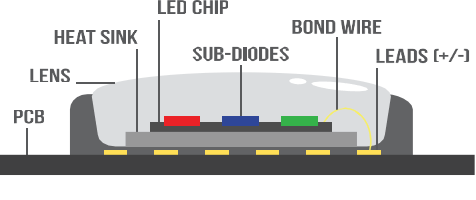

The diode manufacturing process is similar to the display manufacturing process in that each diode made in a production run will exhibit tiny differences from the others on its silicon wafer, even though they were all created with the same materials, ostensibly under the same conditions. Variations between diodes on separate wafers will be even more prevalent. The diode manufacturer will then pick and place the diode from these wafers into their packaging, complete the wire bonding (or wireless bonding), seal the package, and then sell these completed LEDs to display manufacturers. This can lead to inconsistent performance of the display product if the display manufacturer were to indiscriminately purchase a run of packaged diodes from a diode manufacturer without any thought to the variation of optical and electrical specifications between the diodes .

LED display Calibration

. Calibration is a smoothing process performed by display manufacturers before completing a display product. It involves gathering data on every pixel within a display using sophisticated optical equipment and running that data through analyzing software to generate a set of coefficients. These coefficients are then applied to each diode in the display to attune their performance down to the levels of the worst-performing diode

While calibration improves the consistency of the display, it reduces brightness. When not done correctly, it can result in a proportional decline in grayscale quality. As grayscale quality erodes, the slight differences between shades of the same color begin to fade. For example, on a calibrated display, Coca-Cola red may no longer be distinct from other reds. This can be problematic for brands that have paid good money to showcase their specific color

Ultimately, calibration is beneficial as it smooths overall consistency. However, a display should not require frequent calibration as it diminishes brightness and grayscale quality over time, lessening the impact of the displa

It is more complex and to understand the process it is necessary to introduce chromaticity diagrams.

The technique manufacturers use to make sure that the LEDs are similar is called LED binning.

It depends on that the LEDs are placed into similar categories – bins. With the bin defined is the similarity in:

- lumens (Kelvin)

- voltage (forward voltage)

- color (wavelength)

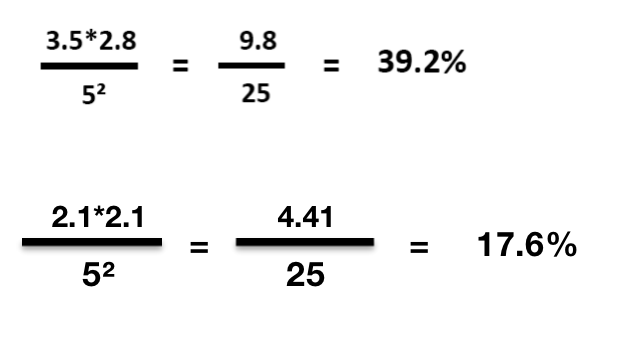

Lumens and color are the most important parameters in LED variability. Forward voltage is largely ignored in the binning process since it can be controlled and adjusted on its own by a display’s driver chip. Binning according to lumens is relatively simple to define – different than Binning LEDs according to color. Each of these measurements comes with an acceptable tolerance ratio.

Tops you may be interested

Industry news

Supply Chain

led Technology

Company News

LED Tips

White Paper

Quality Assurance

Manuels