High-Impact Visuals: With various pixel pitches available from 2mm, 2.5mm, to 3mm, and high brightness levels readable under sunlight, your advertisements will pop, rain or shine, ensuring maximum readability and impact.

LED displays are widely used in museums for interactive and informative presentations. However, traditional LED displays have a significant drawback: when turned off, they leave a large, black area that disrupts the aesthetic decor of the museum, detracting from the overall visitor experience.

Experience the future of visual display technology with Texture LED Display. Our revolutionary display combines high-quality visual output with an elegant, adaptable design, enhancing both functionality and aesthetics.

Enhanced Visual Experience: Provides vibrant, high-resolution displays.

Imagine walking through a renowned art museum where technology and history converge to create an unforgettable visitor experience. As you approach a beautifully framed painting, you notice the BlendView LED Display seamlessly integrated into the wall, appearing as a sophisticated wooden panel that matches the museum’s elegant decor.

Suddenly, the wall comes to life, transitioning into a vibrant, high-resolution screen. It presents an interactive video about the painting, sharing its history, the artist’s inspiration, and intricate details. Visitors are captivated by the immersive experience, allowing them to zoom in on brushstrokes, compare it with other works, and watch interviews with art historians, all without leaving their spot.

In another section, the BlendView LED Display dynamically adapts to different exhibitions, providing themed backgrounds and enhancing storytelling. When displaying ancient artifacts, it blends with the classical architecture, maintaining the aesthetic integrity of the museum.

The BlendView LED Display is also perfect for outdoor facade projects, seamlessly integrating with architectural designs:

Transform Your Space Today!

Ready to revolutionize your environment with the BlendView LED Display? Contact us now to learn more about how our innovative technology can enhance your museum exhibitions and outdoor projects. Don’t miss the opportunity to captivate and impress your audience with a solution that perfectly blends functionality and aesthetics.

Revolutionize Your Delivery Service with Our Advanced LED Delivery Box

In the competitive world of delivery services, standing out is crucial. Our innovative LED delivery box for motorcycles is not just a functional tool but a dynamic advertising platform. Here’s how this cutting-edge product can elevate your business visibility and streamline operations, embedding practicality with high-end technology.

Dynamic Advertising on the Go

– Multiple Display Options: Choose from 1-side, 2-sides, or 3-sides advertising boards to maximize visibility from different angles. Whether you’re cruising through city streets or parked at busy venues, your message gets phenomenal exposure.

Customizable Displays: Tailor your marketing campaigns with our customizable color, size, and design options. The delivery box features a substantial display area of 384×348 mm within a 500x500x500 mm box, perfect for capturing attention.

Technologically Advanced Features

Sustained Operational Efficiency:The LED box is designed to work seamlessly for 8 hours using the motorcycle battery, making it an efficient tool for day-long advertising without frequent recharges.

Real-Time Tracking and Control: Equipped with precise GPS positioning and trajectory tracking, you can monitor and locate your fleet anytime, anywhere. This feature enhances the security and efficiency of your delivery service.

Online Advertisement Updates: Update and manage your advertisements in real-time with our online group control feature. This allows for seamless content updates and campaign adjustments on the go, keeping your marketing fresh and engaging.

Unmatched Safety and Durability

– Robust Waterproof Design: Our delivery boxes are built to withstand the elements, making them ideal for use in any weather conditions. The waterproof design ensures your advertisements and goods are protected.

Comprehensive Security Design: Featuring a four-layer protection system:

– Level One: Industrial-grade power supply with vehicle ACC system control, ensuring equipment safety when not in operation.

– Level Two: A 25A fuse at the power converter’s front end offers secondary protection against electrical mishaps.

– Level Three: Dedicated protection fuses for each power converter guard against overvoltage, overcurrent, and misconnections.

– Level Four: Customized 40-second delay start to minimize electrical interference and protect vehicle operations.

Why Choose Our LED Delivery Box?

– Versatile and Eye-catching: Make your delivery bikes mobile billboards that capture attention while ensuring the safe transport of goods.

– Energy Efficient: With a low power consumption of approximately 15W during start-up, it’s designed to be economical without straining the vehicle’s battery.

– Advanced Security Features: Peace of mind with multi-tiered protection that safeguards both the equipment and the vehicle.

The concepts of Mini LED and Micro LED have been pivotal in the evolution of display technology, marking significant advancements since the early 2000s. These technologies offer refined visual experiences and are defining the future of displays with their ultra-fine pixel pitches and innovative packaging methods.

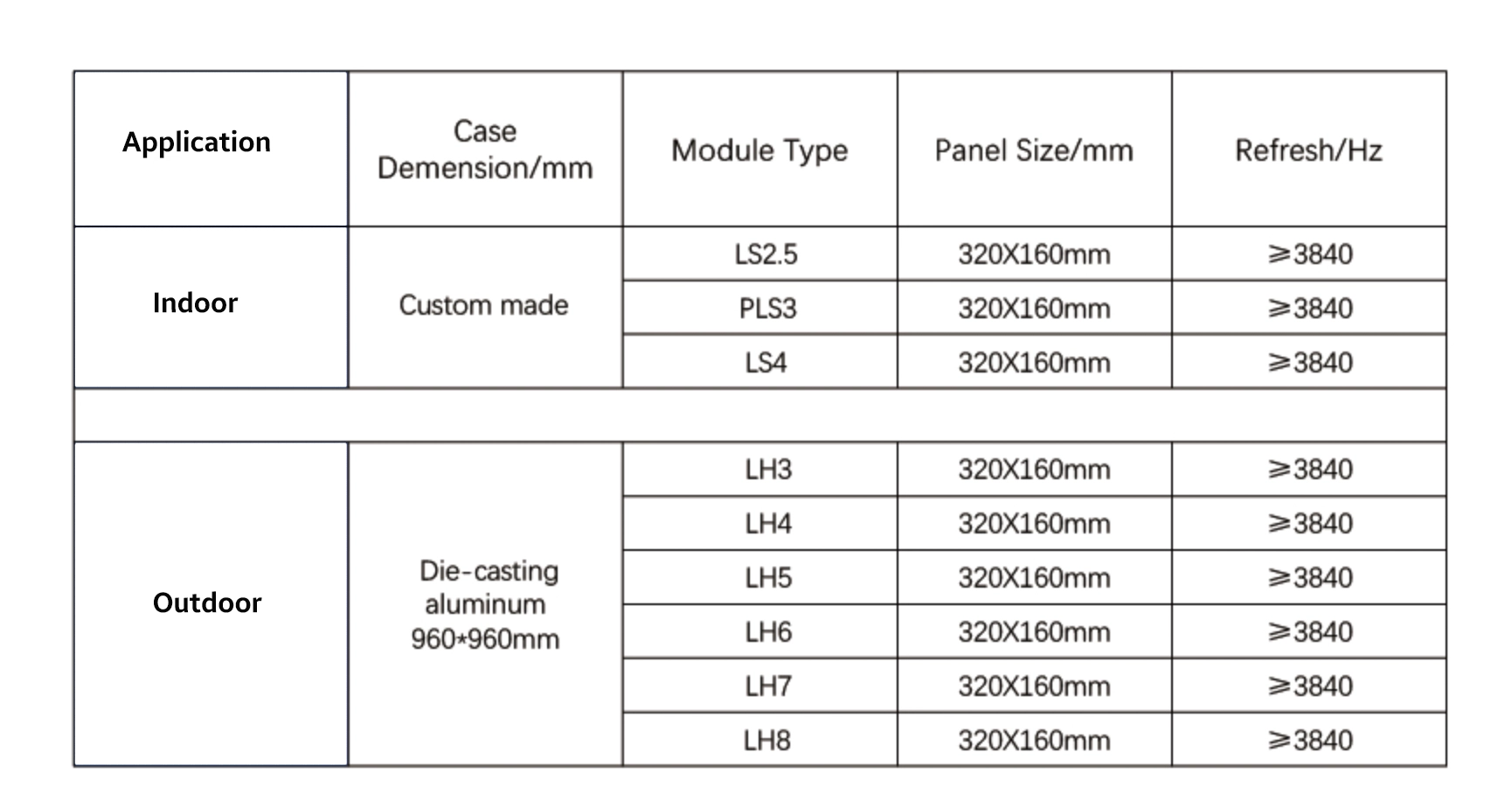

Upstream Suppliers and LCD Manufacturers: Typically, these stakeholders define Mini LED and Micro LED based on chip size, the structure (either formal or flip), and the method of film transfer, which often involves a substrate-less structure.

Large-Format Display Manufacturers: This group tends to classify these technologies by pixel pitch and packaging method, focusing more on the application in large-scale displays.

In the rapidly evolving world of display technology, Micro and Mini LEDs are leading the charge towards brighter, more efficient, and more precise screens. As a seasoned manufacturer specializing in cutting-edge Micro and Mini LED technology, we offer a wide range of products that cater to diverse industry needs, providing OEM and ODM services that promise unparalleled precision and customization. Discover how our LED displays, ranging from 0.4mm to 1.5mm, can elevate your projects, ensuring top-tier quality and innovation.

Unpacking Micro and Mini LED Technologies: Micro and Mini LED technologies represent a significant leap forward in display solutions, offering several advantages over traditional display technologies. Here’s what makes these tiny powerhouses stand out:

1.Unmatched Precision and Quality:

2.Customization at Its Best:

3.Durability and Energy Efficiency:

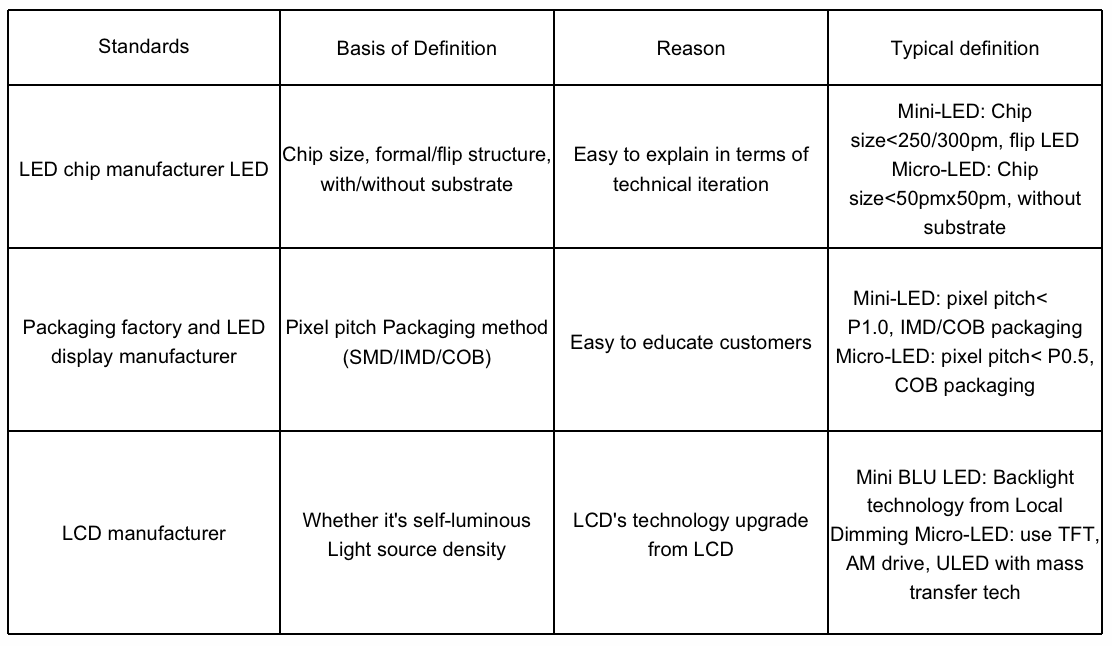

As a leading OEM/ODM manufacturer with esteemed partnerships including industry giants like Absen, Unilumin, Lanbo, and Creatled, we excel in delivering advanced Micro COB LED display solutions that redefine how visual content is experienced. Our commitment to innovation is reflected in the high performance and versatility of our products, tailored to both dynamic indoor settings and challenging outdoor environments.

– Exceptional Brightness:

– Indoor Micro LED displays achieve up to 2000 nits.

– Outdoor COB Micro LED displays can reach up to 4000 nits.

– Diverse Product Range:

– Fixed installation Micro LED displays sized at 600×337.5mm with a 16:9 aspect ratio.

– Rental Micro LED displays measuring 500x500mm, suitable for varied event needs.

– Flexible Mini COB LED displays designed for creative applications and outdoor breakthroughs.

– Enhanced Durability:

– Proven stability and functionality in extreme cold, with performance unaffected at temperatures as low as -20 degrees Celsius.

– Energy Efficiency:

– Incorporation of common cathode LED technology, significantly reducing power consumption and lowering heat emission.

Join us as we push the boundaries of digital display technology, transforming environments and crafting exceptional visual experiences with our state-of-the-art Micro COB LED displays. Each product we develop is a testament to our dedication to quality, innovation, and environmental responsibility.

Explore the Future of Visual Displays:

With our extensive experience and a robust lineup of high-quality, customizable LED solutions, we are equipped to enhance any project, offering unparalleled visual displays that captivate and engage. Let us help you make a visual impact that lasts.

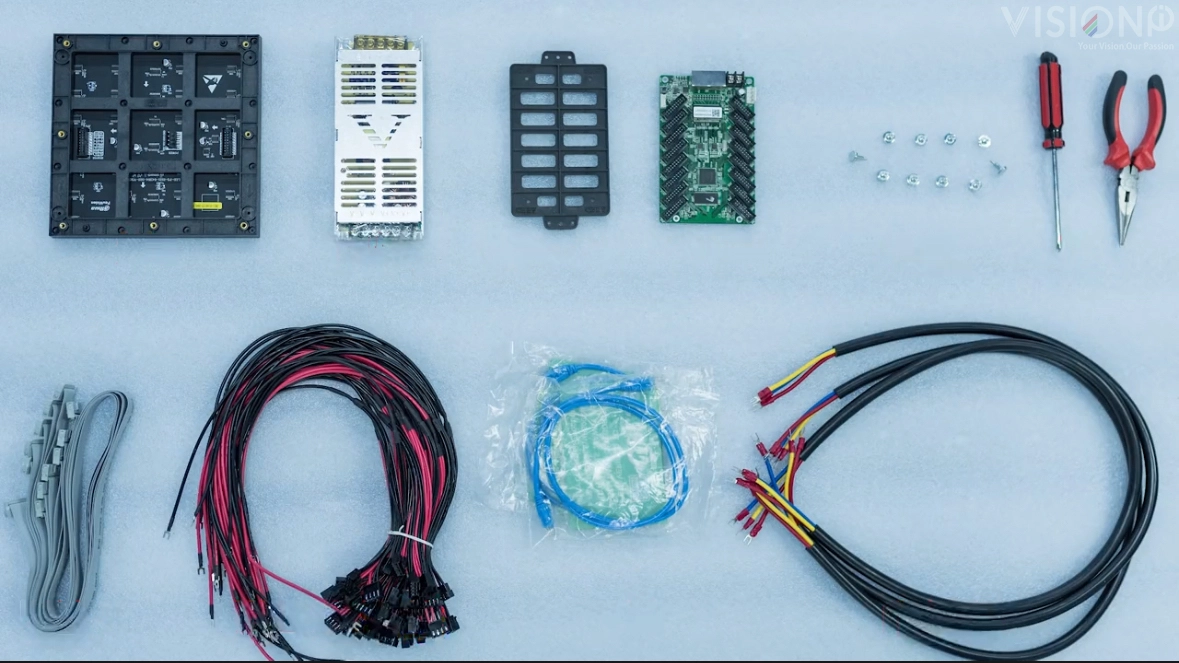

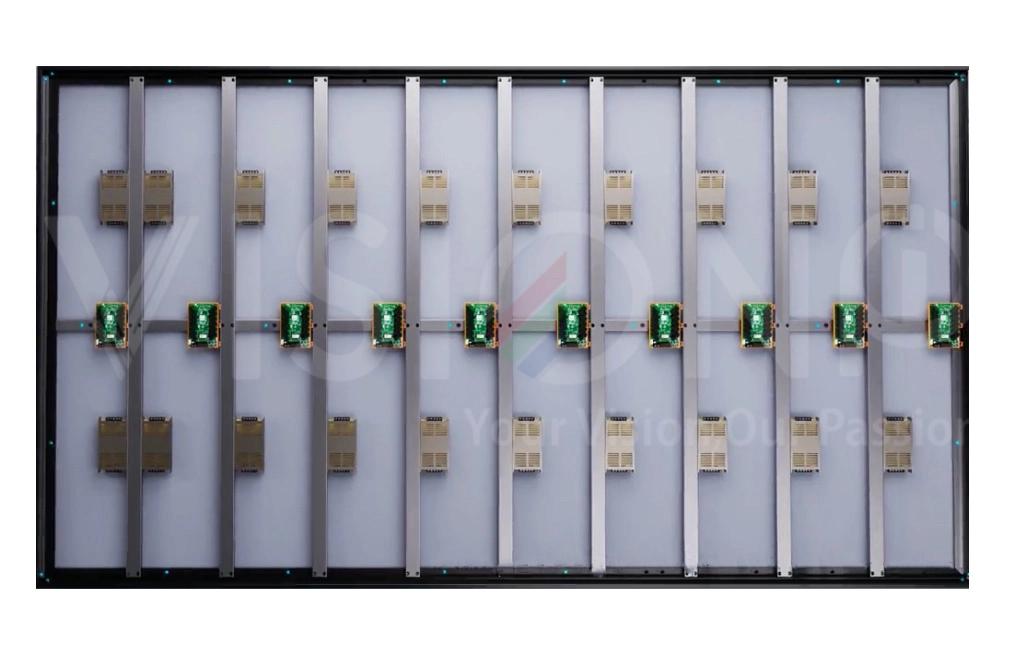

In the evolving world of digital displays, modular LED displays are gaining traction for their unmatched flexibility and efficiency. Unlike traditional LED screens that come pre-assembled in bulky cabinets, modular LED displays consist of independent modules that can be directly installed onto a frame. This innovative approach not only allows for customized screen sizes but also offers significant savings in space and cost. In this blog post, we’ll delve into the advantages of modular LED displays and provide a comprehensive guide on how to install them effectively.

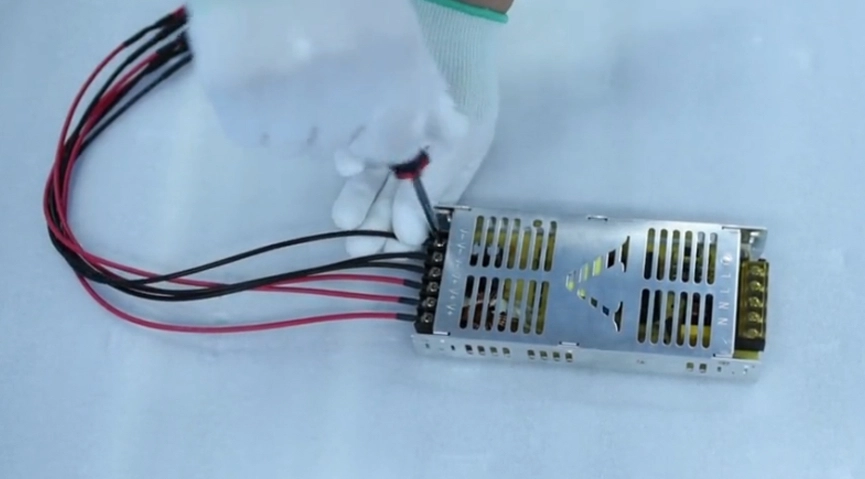

4. 5V Power Cable Wiring: Essential for powering the LED modules, the 5V power cables should be connected from the power supply to the LED modules ensuring secure and stable connections. Use appropriately rated cables to handle the current requirements and minimize voltage drop across long distances.

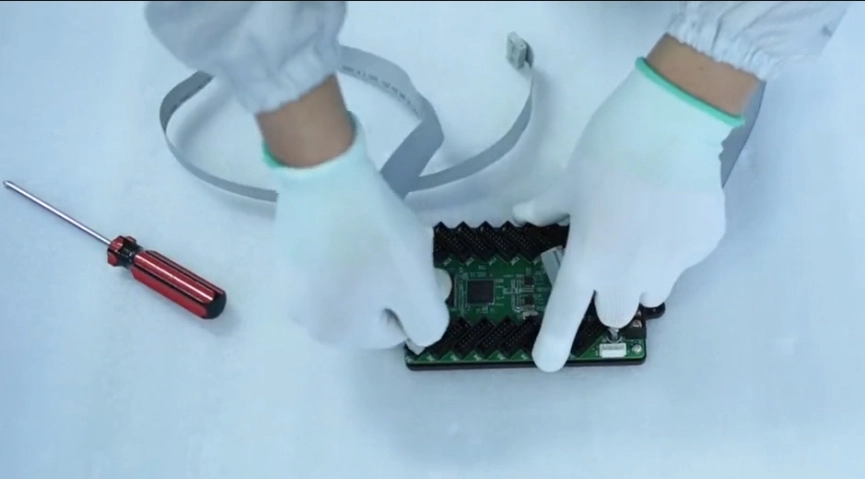

5.Receiving Card Wiring: This involves connecting the receiving card to the LED modules using flat cables. The flat cables transmit data signals and need to be carefully routed to avoid interference and ensure stable signal transmission.

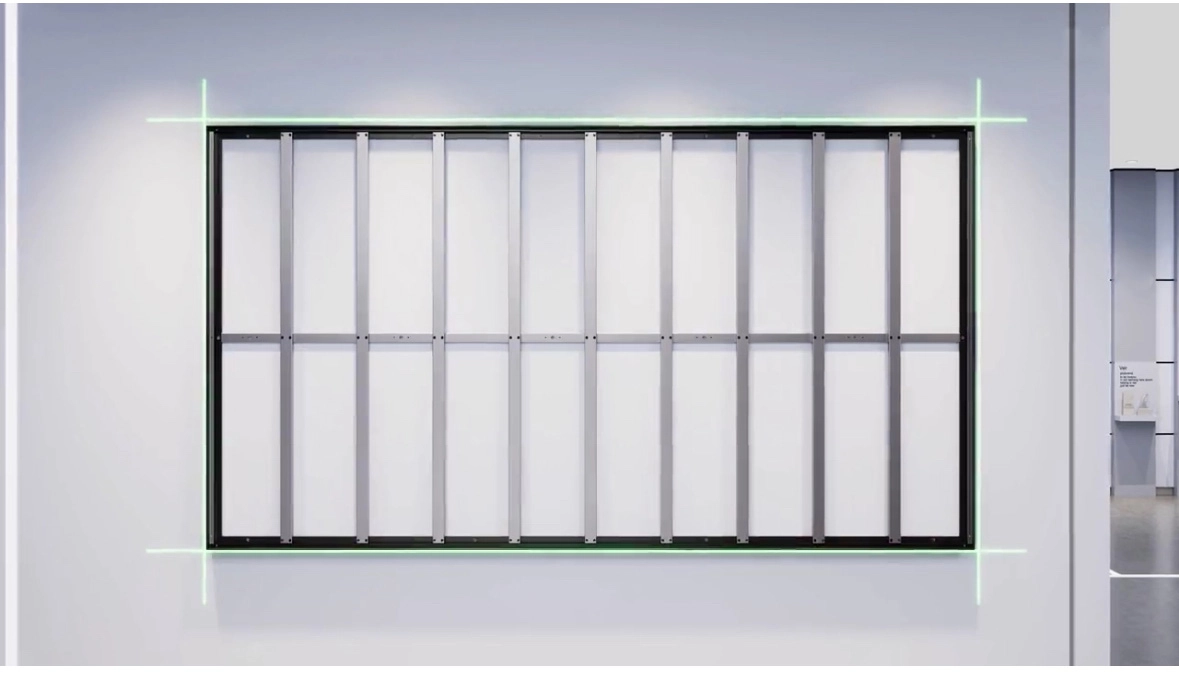

3.Frame Setup: Construct the Supporting Frame: Depending on the design, this could be a simple rectangular frame or a more complex custom shape. The frame should provide stable and even support for the modules.

4.Secure the Frame: Fix the frame securely to the wall or structure, making sure it is level and sturdy.

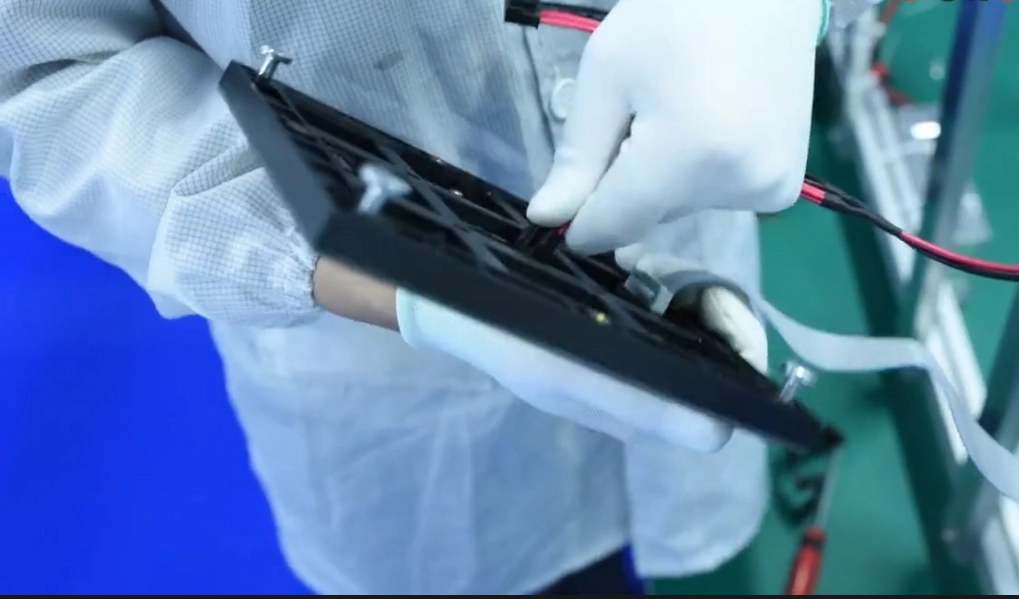

Installing LED Modules

Interested in exploring the potential of modular LED displays for your business or next event? Contact us today to find out how our cutting-edge solutions can be tailored to fit your unique requirements.

320*480mm LED Cabinets

Advantages of Plastic-Cabinet-Type LED Displays

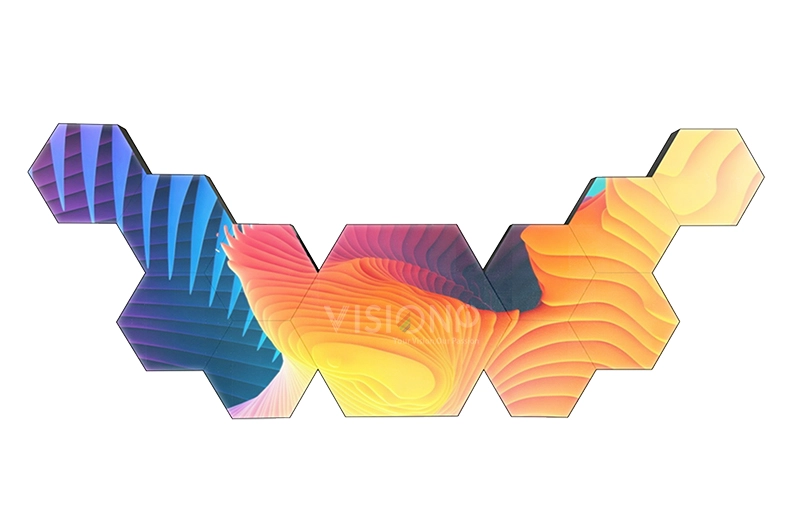

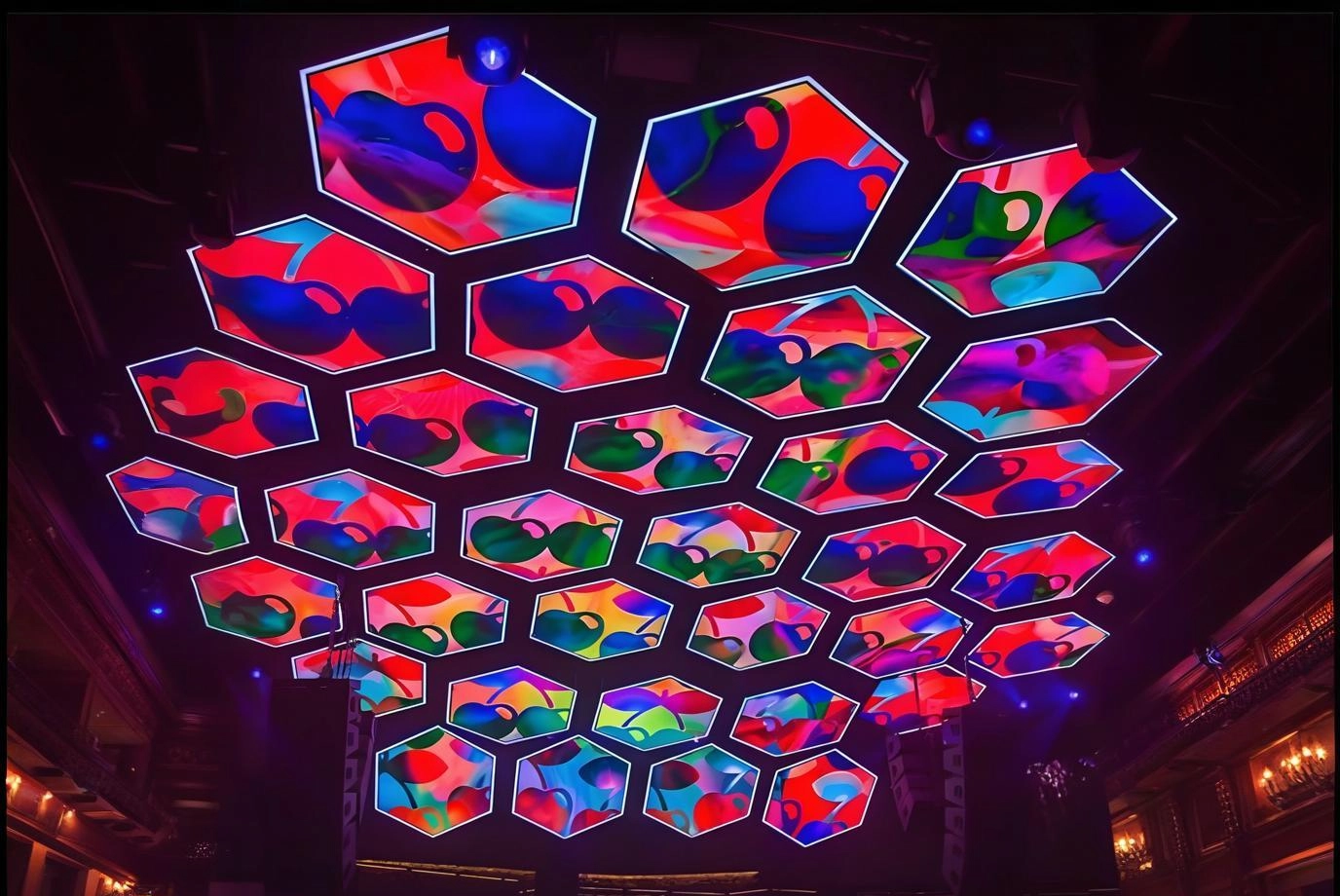

In the era of immersive branding, the NSE Hexagon LED Display redefines spatial storytelling through its modular honeycomb technology. Unlike traditional square panels, these precision-engineered hexagonal modules unlock infinite design possibilities for architects and marketers alike.

Shape-Shifting Versatility

Plug-and-Play Intelligence

Pixel-Perfect Clarity

Corporate Identity Amplifiers

Turn company lobbies into brand galaxies:

Stage Design Revolution

Concert/Event Applications:

Retailtainment Powerhouse

Mall atriums transformed with:

↓ Limited Stock Alert: Book Your Hexagon LED Prototype Today ↓