Transparent LED Poster

Transparent LED Poster Display

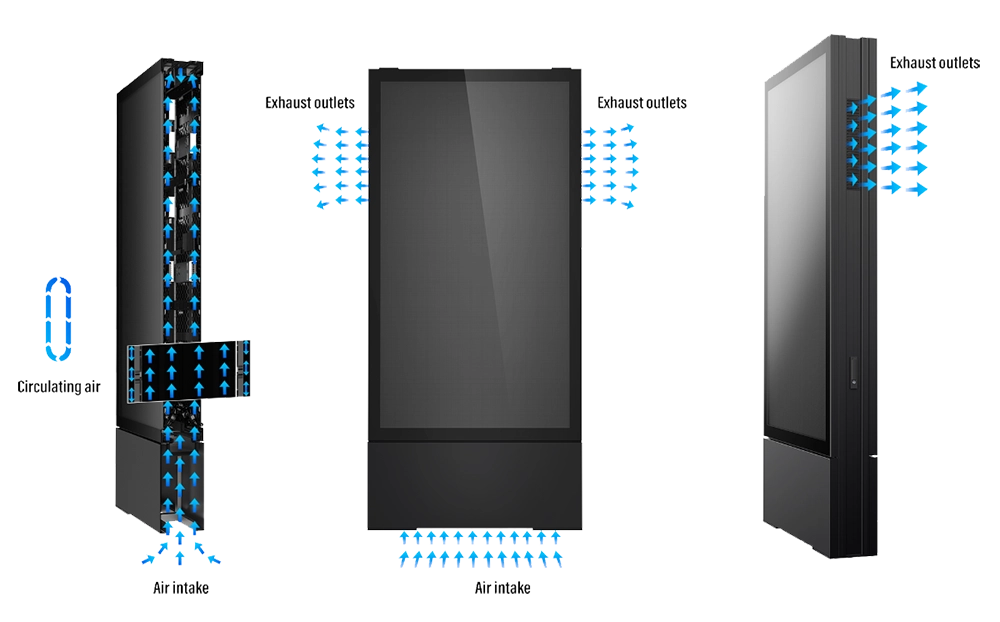

Transparent LED Poster Screen: A Modern and Versatile Promotional Tool If you want to replace your traditional roll-up banner with a more modern and versatile promotional tool, you should consider the Transparent LED Poster Screen. This innovative product allows you to play video and other dynamic advertising content on a transparent LED display that can be wirelessly controlled through mobile, WIFI, and other methods. With its clear and vivid display, you can attract more customers and convey your promotional message effectively.

Some of the key features of the Transparent LED Poster Screen are:

- Plug and Play: You can easily set up and use the screen without any complicated installation or configuration.

- Ultra transparency: The screen has a high transparency rate of up to 80%, which means you can see through it and enjoy the view behind it.

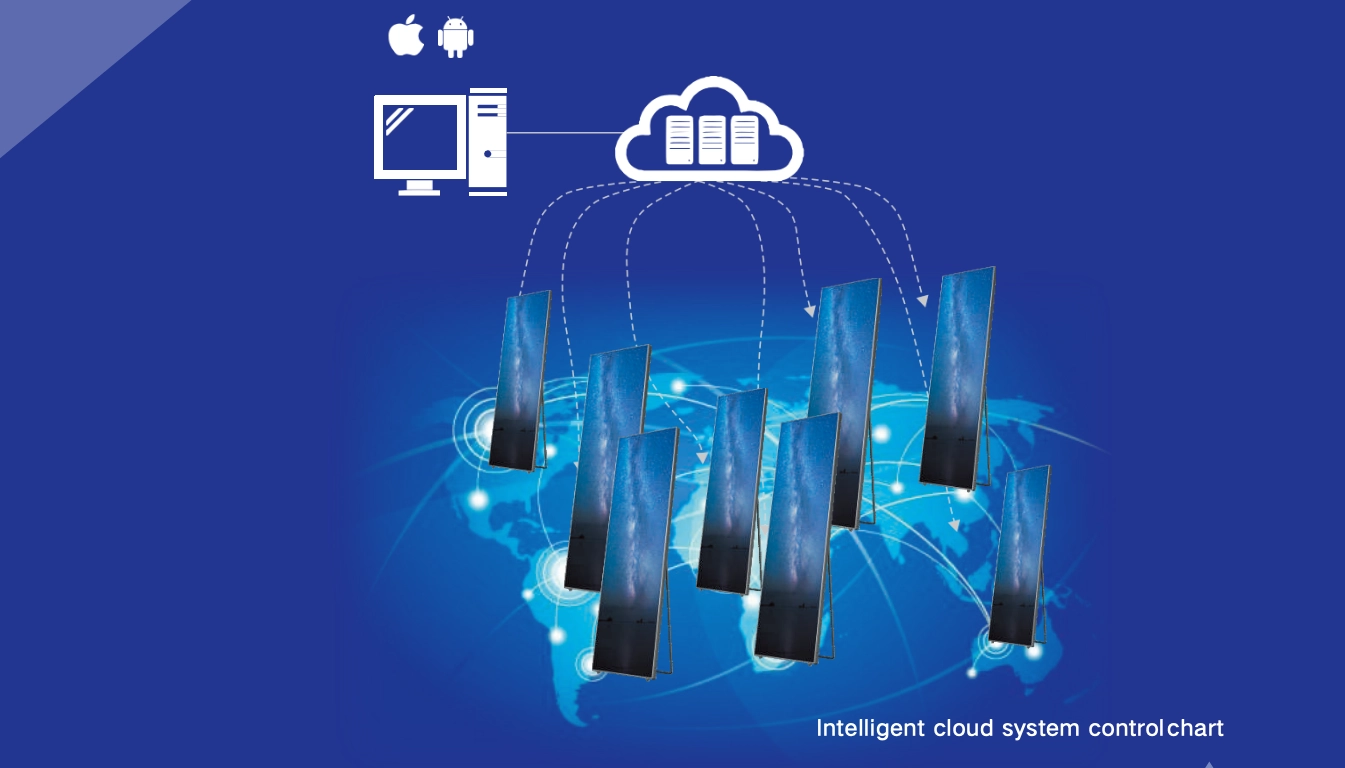

- Wifi control: You can remotely control the screen content through your mobile device or computer, using WIFI or other wireless methods.

- High definition: The screen has a high resolution of up to 1920×1080 pixels, which means you can display sharp and clear images and videos.

- Hanging or standing: You can choose to hang the screen on the wall or ceiling, or stand it on the floor or table, depending on your preference and space availability.

Transparent LED Poster Features

High-Resolution Transparent LED Poster Display

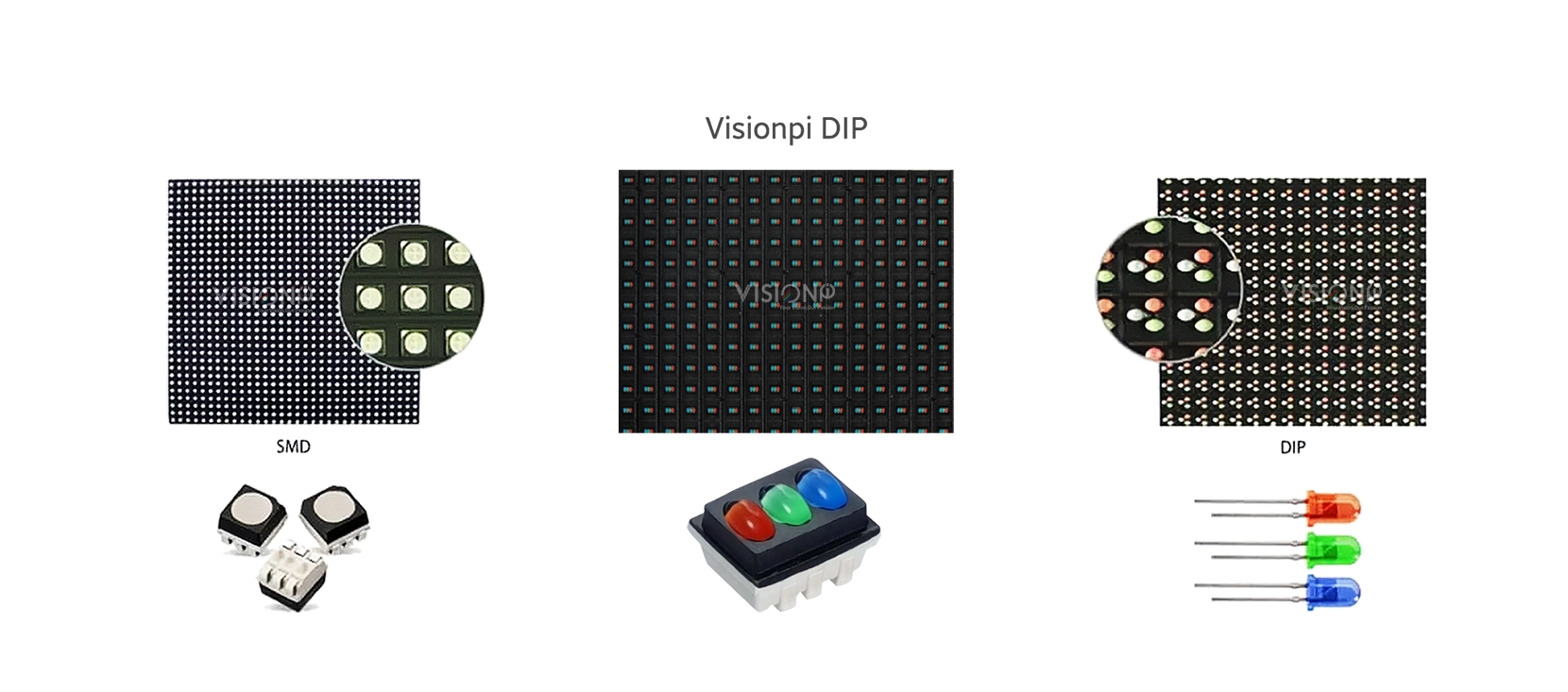

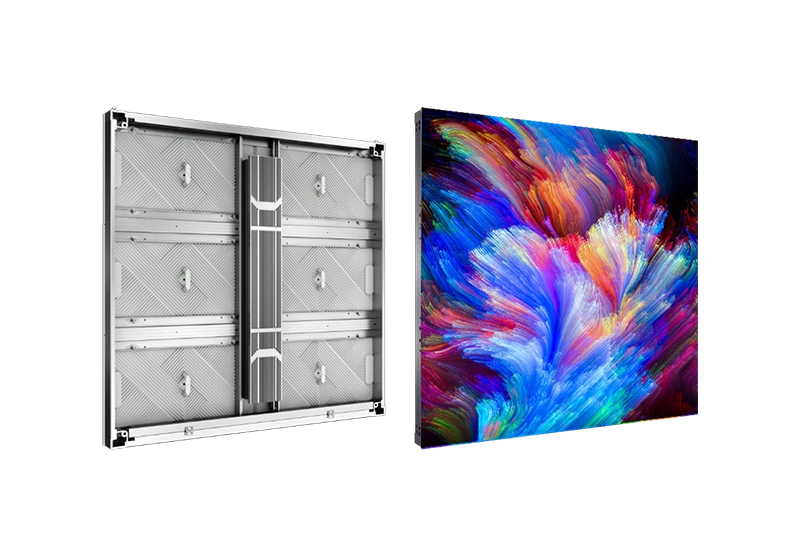

- P2.8 LED transparent Poster is a transparent LED screen that can be applied to different scenarios.

- It can be quickly installed and used, and the content can be controlled by a mobile phone.

- It perfectly realizes the integration of screen and building, and integrates media functions into the building without damaging the appearance of the building.

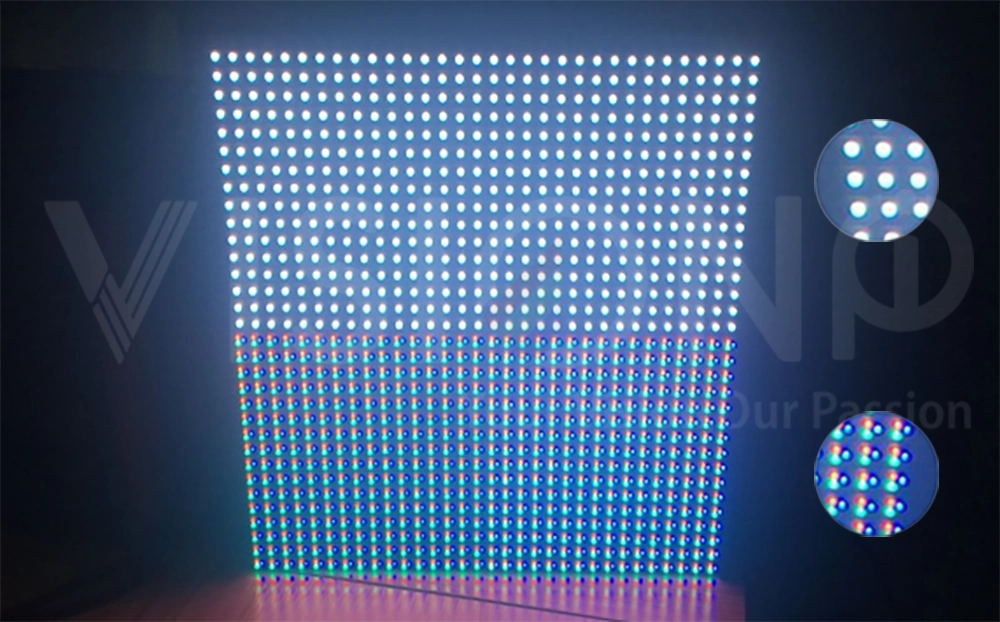

- With a transparent display, HD pixel, seamless screen, energy saving, and environmental protection features.

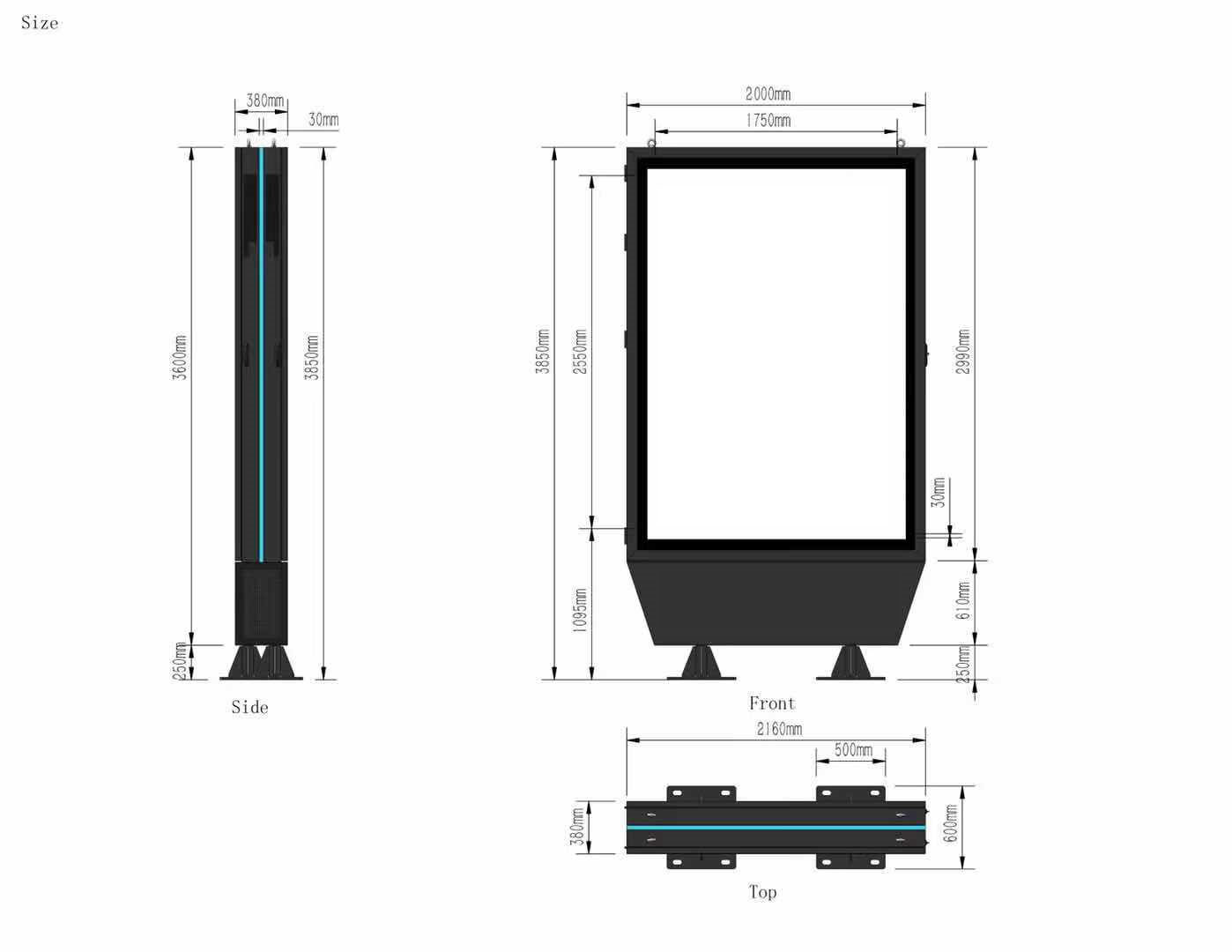

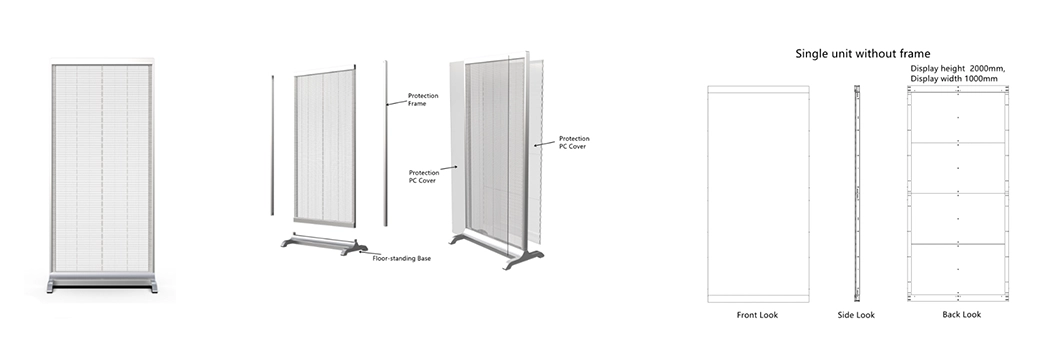

* Display Area: Width 1000mm, Height 2000mm

* Note: The display area can be customized multiple of 500mm

* Pixel Pitch: 2.6-5.2mm/3.91-7.81mm

* Brightness: >1000 (cd/m²)

* Indoor use

* Voltage: 100-240VAC

Smart Cloud Management

Customize Size.

Multiple size and color available. : 1000x500mm ,1000x1500mm;1000x2000mm;2000mx3000mm.

Double Sided LED Poster.

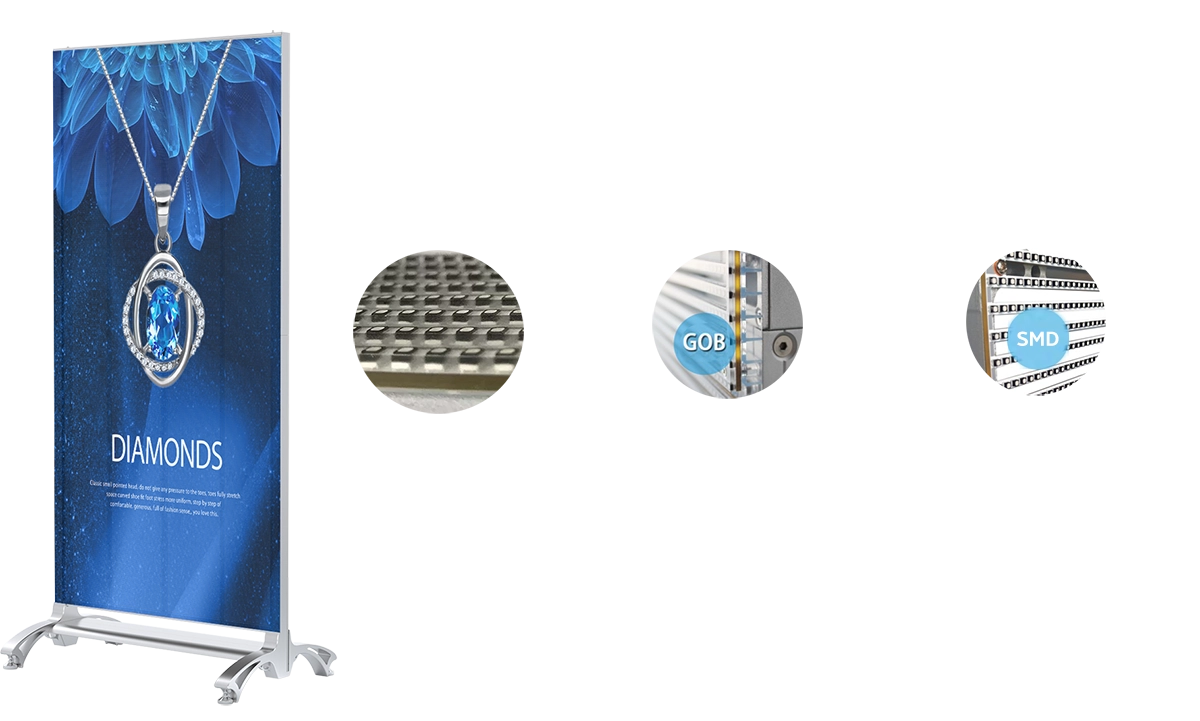

GOB Transparent LED Poster

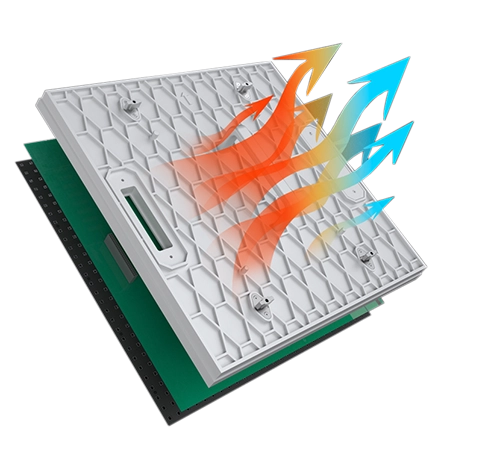

GOB Tech. protect the SMD LEDs

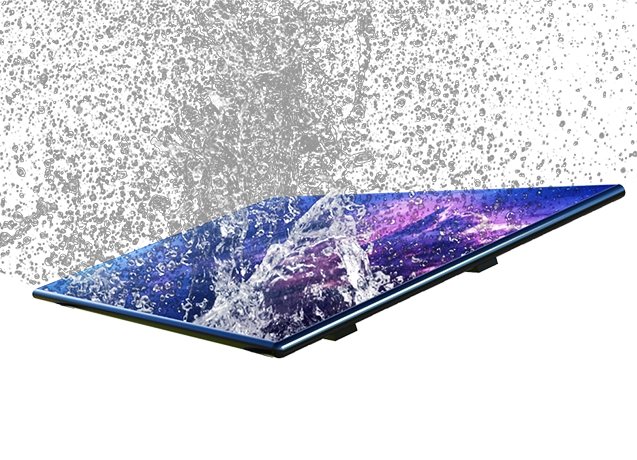

Glue on Board technology, the LED surface is covered by glue that can protect from dust, water (IP65 Waterproof), and attack. GOB light board protection functions make it moisture-proof in humid regions and prevent it from falling over in crowded places.

Hologram Invisible Transparent LED Poster

- Plug and play, no need for assembly, suitable for a variety of installation methods

-

- Save time and hassle with easy installation and flexibility

- Choose the best option for your space and needs

- Easy to deliver, removable and mobile

- Enjoy convenience and portability with a lightweight and compact design

- Move or relocate your display as you wish

- Full screen transparent and invisible, without any obstruction to vision and lighting

- Create a stunning visual effect with a see-through display that blends in with the environment

- Showcase your content without blocking the natural light or the view behind the screen

- The display panel has no splicing structure, and the transparent display occupies more than 95% of the whole machine

- Achieve a seamless and smooth display quality with no gaps or borders

- Maximize the transparency and clarity of your screen with minimal frame

- Hd display quality! The whole machine has 260,000 pixels. Stable picture, rich and delicate color

- Impress your audience with high-definition resolution and vivid colors

- Ensure a consistent and reliable performance with a stable picture

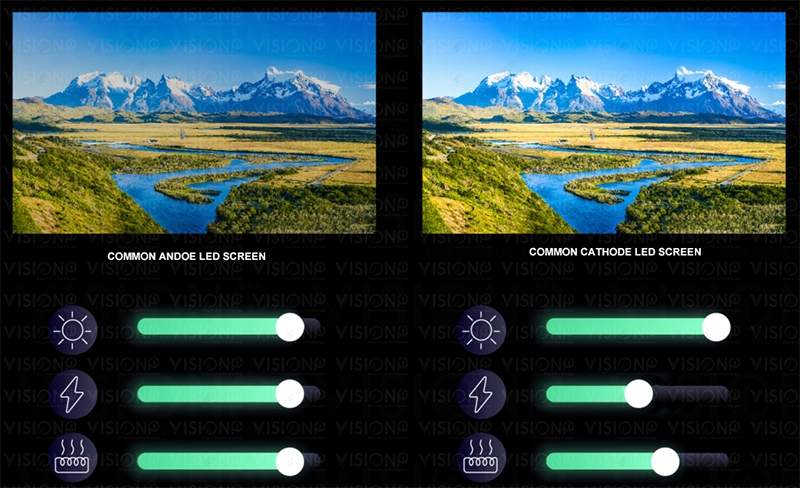

- Horizontal and vertical pixels equal spacing, lamp drive integration static scanning, 16bit gray level

- Enhance the sharpness and contrast of your images with equal pixel spacing and high gray level

- Optimize the brightness and power consumption of your screen with lamp drive integration

- Immersive floating imagery, naked-eye AR commercial display experience

- Attract attention and engagement with a 3D-like floating imagery that creates an illusion of depth

- Provide a novel and interactive experience with naked-eye augmented reality technology

- High brightness 5000cd/㎡

- Ensure a clear and visible display even in bright environments

- Adjust the brightness level according to your preferences and needs

- High contrast ratio 9000:1

- Display a wider range of colors and shades with a high contrast ratio

- Make your images stand out with a strong contrast between light and dark

| LED Transparent Poster Specification | ||

| Model | P3.91 | P2.6 |

| Pixel Pitch (mm) | 3.91*7.8 | p2.6-5.1 |

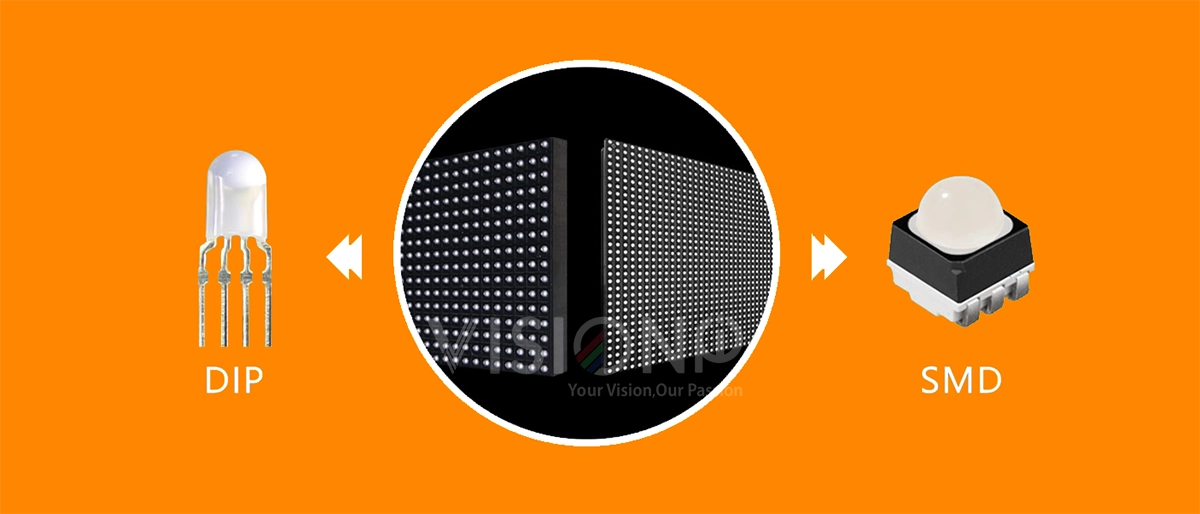

| LED Lamp Model | SMD 1921 | SMD 1921 |

| Module Size(mm) | 500*250 | 500*250 |

| Module Resolution | 128*32 | 128*32 |

| Driving Mode | constant current | constant current |

| Display Area(W*H) | 1M*2M | 1M*2M |

| Display Resolution (W*H) | 256*256 | 384*384 |

| Cabinet Module Number | 2*6 | 2*6 |

| Pixel Density (dot/pcs) | 48640 | 73728 |

| Brightness (cd/m2) | 1200-2000 | |

| Max.Consumption(W/pcs) | 1200 | |

| Ave.Consumption(W/pcs) | 400 | |

| Best Viewing Distance (m) | ≥4 | |

| Viewing angle | H:140;V:140 | |

| Control Mode | Synchronization or Asynchronization | |

| Refresh Rate | 1920HZ/3840HZ | |

| Max Gray Level | 14bits | |

| Repetition Frequency | 60HZ | |

| Signal Input | HDMI, DVI, VGA, RF, S-Video, RGB, RGBH, YUV, YC&Conposition, etc | |

| Working Voltage | AC110V/220V±10% | |

| Working Temperature | -20~+50°C | |

| Life Span Time | ≥100000hours | |

How to Use an LED Poster Display?

An LED poster display can be used for various purposes and applications, such as:

- Advertising and promotion: An LED poster display can display attractive and informative ads and promotions for products, services, events, and brands. It can also display social media feeds, customer reviews, and QR codes to increase engagement and conversion.

- Information and communication: An LED poster display can display useful and timely information and communication for the public, such as news, weather, traffic, schedules, announcements, and alerts. It can also display interactive maps, directories, and menus to guide and assist the visitors.

- Entertainment and education: An LED poster display can display entertaining and educational content for the audience, such as movies, videos, games, and quizzes. It can also display artistic and cultural content, such as photos, paintings, and poems, to inspire and enrich the audience.