LED display packaging has developed from early-days DIP (dual in-line package) to today’s multiple packaging methods such as SMD, IMD, and COB,. These methods have reshaped the industry.

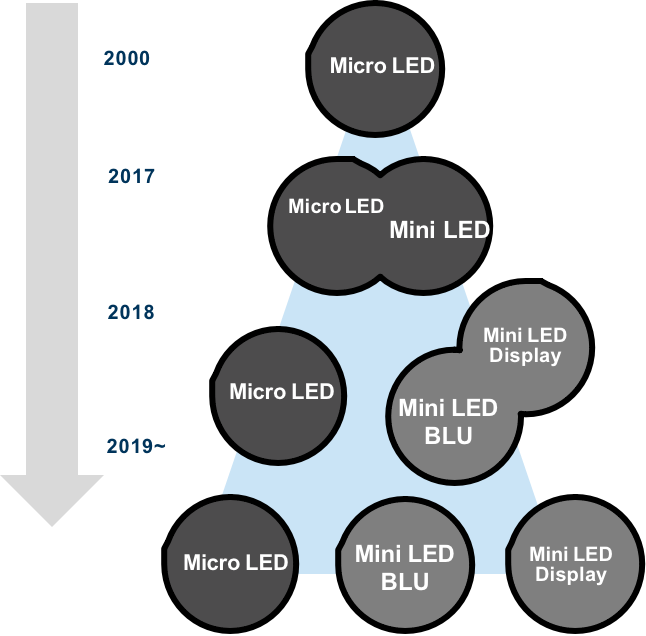

The Micro-LED concept was first put forward in 2000. In 2017, Mini-LED, as a subordinate form of Micro-LED, was introduced as a groundbreaking product, officially opening a new chapter of Mini and Micro-LED.

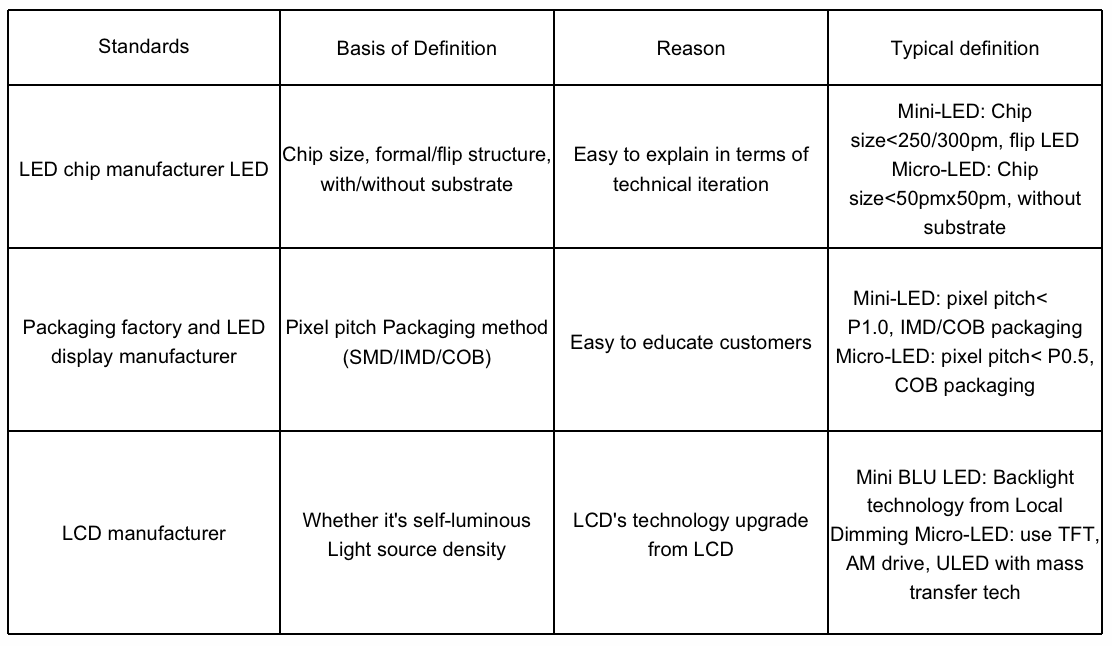

Definitions of Mini/Micro-LED vary in the industry. On one hand, upstream suppliers and LCD display manufacturers tend to define Mini-LED and Micro-LED by chip size, formal or flip structure, and film transfer (substrate-less structure). On the other hand, large-format display manufacturers are more inclined to define Mini-LED and Micro-LED by pixel pitch and packaging method.

I1.In terms of pixel pitch. products at or below 2.5mm are defined as fine-pitch, which serves as an umbrella term. Within the fine-pitch range, Mini-LED is defined as products with pixel pitch ranging from 0.4mm to 1mm, whereas Micro-LED is defined as products with pixel pitch below 0.4mm.

LED displays have been used in commercial applications for more than a decade. IMD extends the service life of the SMD supply chain and serves as a smooth transition from SMD to finer-pitch products. COB’s growth paves the way for Mini- and Micro-LED products in the future.

3.In terms of Chip Size. Mini LEDs tend to measure below 200 microns , while micro LEDs can be as small as 100 microns, or 0.004 inches.

Market competition brought by Mini & Micro-LED

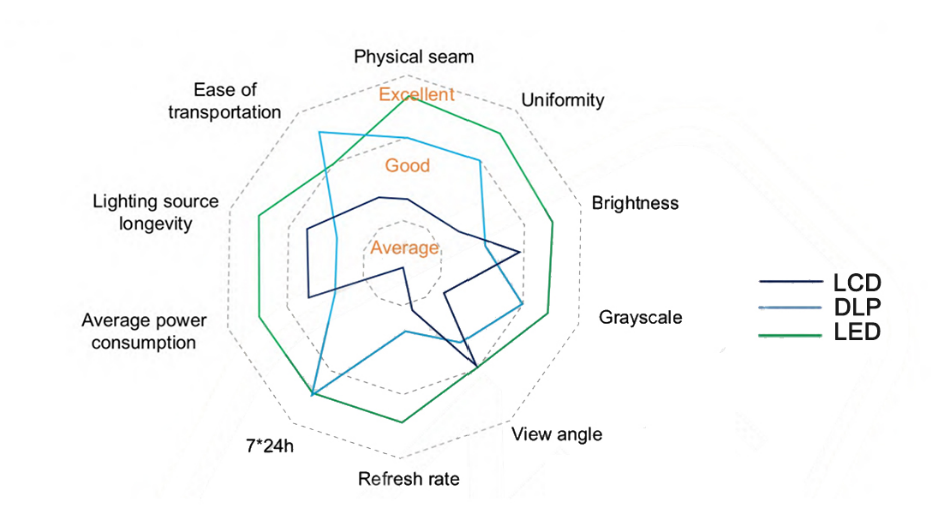

With LED displays evolving to the fine-pitch level, viewing distance is also greatly reduced, which broadens the applications for fine-pitch LED displays. Indoor LED displays start at 4mm, and fine-pitch products start from 2.5mm. Further finer pitch in the sub-1 mm range will bring LED displays to the consumer market and ultimately compete against LCD and laser projections in the TV market.

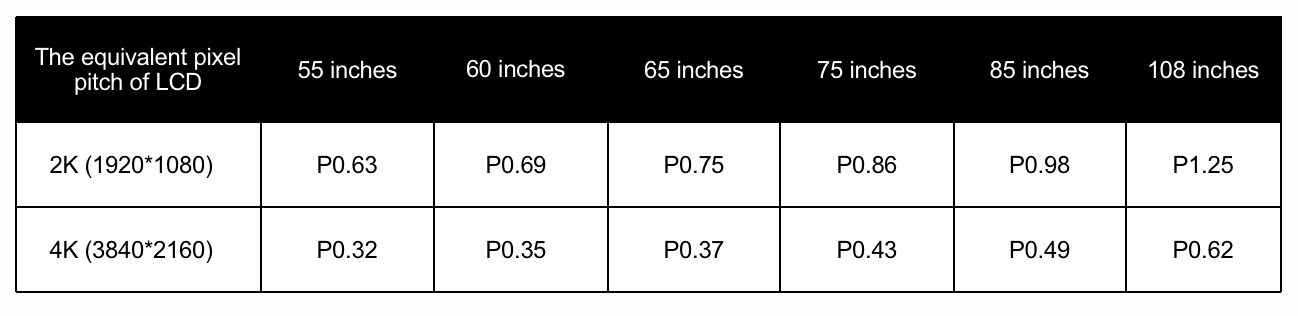

Take the 108-inch LED display as an example (600*337.5mm LED panels in 4×4 panel array). When the pixel pitch is P1.25, P0.62, and P0.31, the resolution can be 2K, 4K, and 8K respectively. According to the Rec. ITU-R BT.1769 reference standard of ITU (International Telecommunication Union), the optimal horizontal viewing angle under this resolution is 32°, 58°and 96°respectively, from which the optimal viewing distances are estimated to be 4.17m,2.02m and 1.01m respectively. The above viewing distance makes it possible for LED displays to be used in living rooms as a TV. The viewing distance of 2.02m and 1.01m is suitable for the living room area of most houses. From another perspective, if we convert the resolution of 2K and 4K LCD TVs into pixel pitches of 53” LED displays, we can find that 2K LCD TV’s pixel pitch is between 0.6mm and 1.2mm, and 4K LED TV’s pixel pitch is between 0.3mm and 0.5mm. Up to now, SONY, Samsung, and other display manufacturers have launched large-size Mini/Micro-LED display products up to 120 inches based on a modular design. If we ignore their sky-high price, these products are perfect for living room applications.

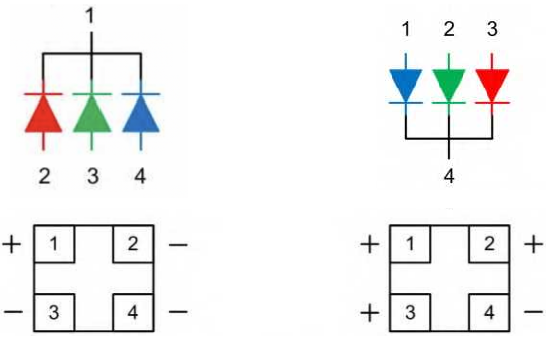

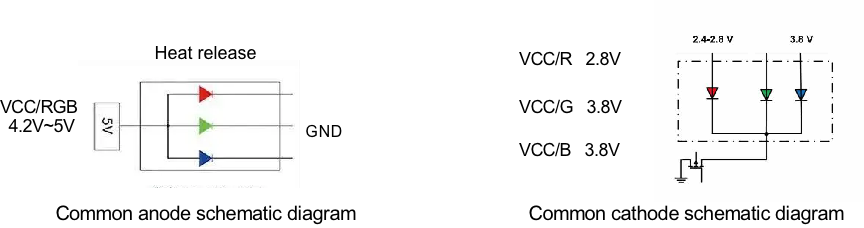

Common anode LED screen has all of the anodes of the individual LEDs connected together and to a common terminal, while the cathodes of each LED are connected separately.

A common cathode LED screen is also called” energy-saving led display”. It has all of the cathodes of the individual LEDs connected together and to a common terminal, while the anodes of each LED are connected separately.

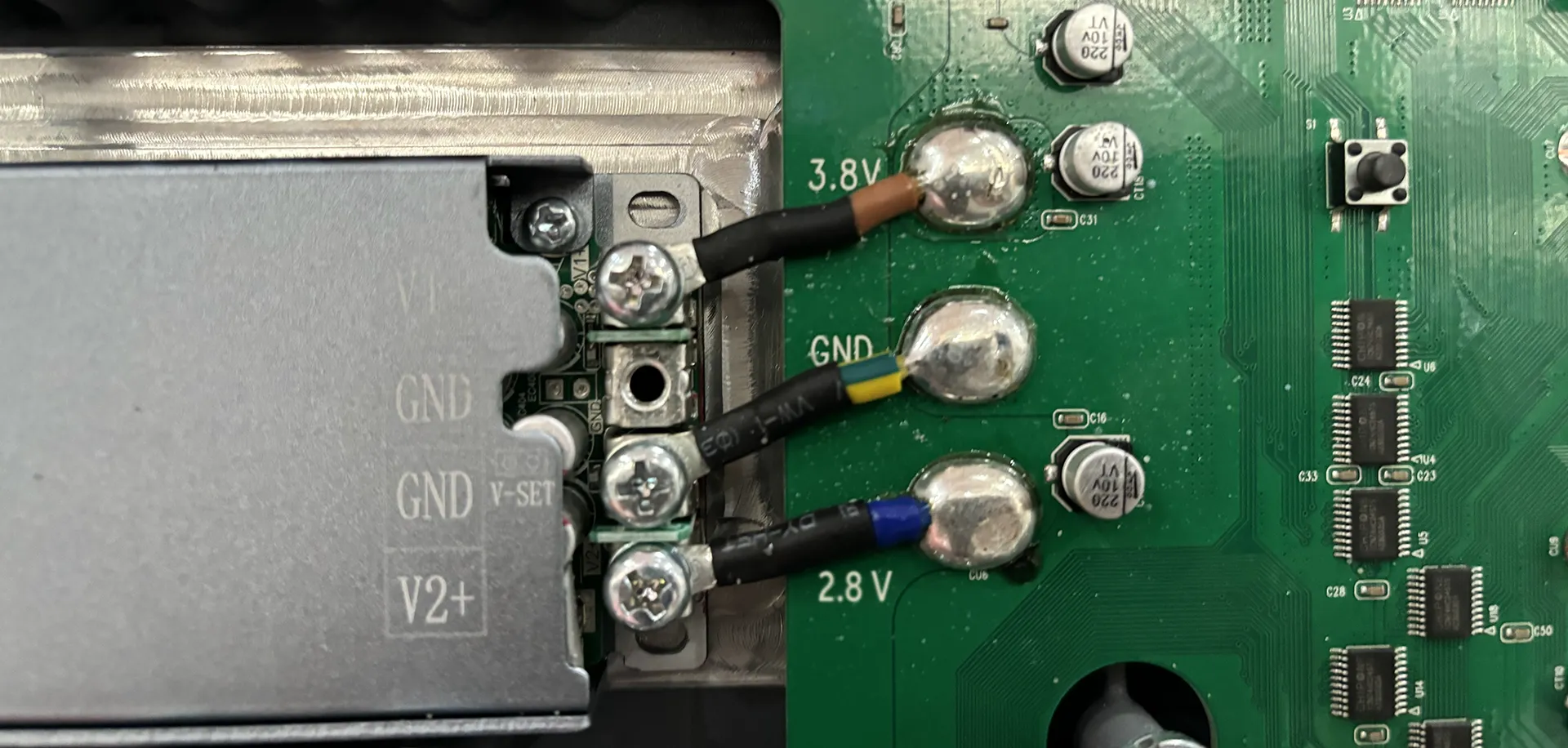

common cathode”. It is an energy-saving power supply technology for LED displays where the current first passes through the LED chips and then reaches the negative pole of the driving IC, hence the name “common cathode”. The voltage drop and current loss can be reduced by using the independent voltages power supply method. Additionally, this technology can separate and precisely power the red, green, and blue LED chips. LED professionals know that the rated power required for the red, green, and blue chips is different, and ordinary power supply methods cannot separate them and can only provide them with the same power. With an independent voltage power supply, the red, green, and blue LED chips can be separately and accurately powered, providing different voltages to them under the same current, which can ensure that they work at their rated power, thereby improving energy utilization and reducing energy consumption.

Common Cathode Fine Pixel Outdoor LED Display

In the early stage, LED displays were mostly used for outdoor applications using larger pitch products, which did not have a physical space limit for driver ICs as they were designed with static scan drive. However, when LED displays began to be used for indoor applications using smaller pitch products, the space available for electronic components was squeezed, and as a result, dynamic scan drive (line-scanning drive) based on time-division multiplexing (TDM) came into being.

Under line-scanning drive mode, LED displays can be categorized into two types: the common cathode and the common anode.

As the name implies, common anode means individual LEDs are connected via their positive ends and driven by negative ends; and common cathode means individual LEDs are connected via their negative ends and driven by positive ends, and in common cathode mode, R, G, B chips are separately powered with voltage and current precisely distributed to red, green, and red diodes, and the current passes the diodes then to the negative ends of ICs.

■ In common anode mode, the current of LED displays flows from PCB to LED diodes, and the RGB LEDs are powered with the same power source at the same power rate, and therefore the forward voltage drop is increased.

■ In common cathode mode, the LED display’s current first passes through LED diodes with R, G, and B LEDs separately powered. Voltage and current are precisely distributed based on individual needs, then to the negative ends of ICs. The forward voltage drop is reduced, and as a result, there is less internal conduction resistance.

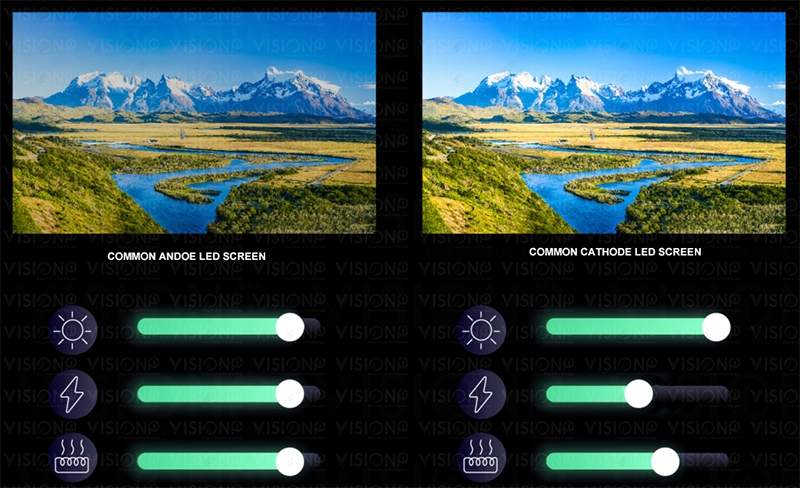

■ In common anode mode, the LED display provides RGB LEDs with a unified voltage higher than 3.8V (such as 5V), therefore the power consumption is high.

■ In common cathode mode, the LED display provides RGB LEDs with separate voltage based on actual needs (2.8V for the red LED, and 3.8V for the green and blue LEDs). Because of this separate and precise power supply, the power efficiency is higher. Consequently, less heat is produced as less power is consumed.

■ Based on accurate power control, common cathode technology can reduce the power consumption of the entire system by reducing the red LEDs’ supply voltage. Moreover, there are no extra line-scanning devices needed to achieve this. By using common cathode technology, LED displays can reduce excessive heat and power consumption, pixel failure rate, and ghost lines (tailing effect), thus improving LED displays’ overall performance

■ Common cathode technology reduces forward voltage drop by reducing the supply voltage of red LEDs, however, this requires the use of more power supplies, which further increases the complexity of the component layout on PCBs. Currently, the key supporting components related to common cathode technology are LED diodes, power supplies, and driver ICs. These components have market-proven solutions for common anode technology but are still in the early stages of common cathode technology.

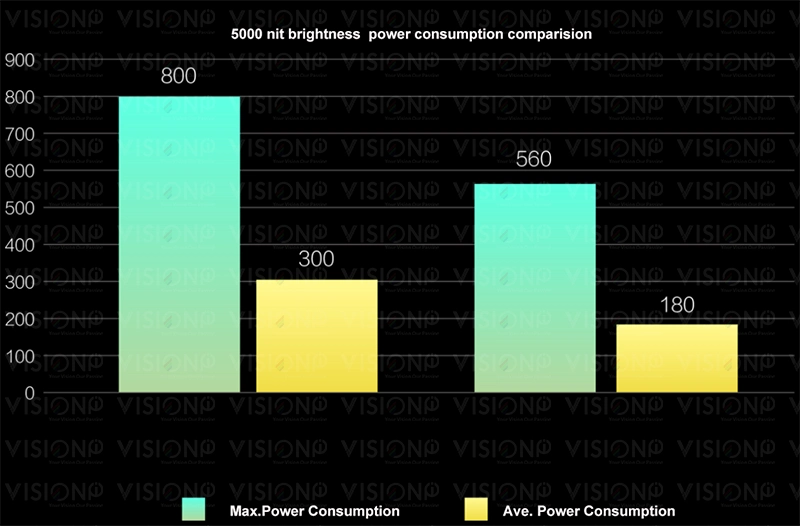

Assuming that under common anode mode, a 5V voltage is used as the unified power, under common cathode mode a 2.8V is used for red LEDs, and all other conditions are the same if the current of red LEDs accounts for 40% of the total current, then we can quickly calculate the percentage of power saved: 40%*(5-2.8)/5=17.6%. If the ed LED current accounts for 50% of the total current, then we can save 50%*(5-2.8)/5=22%, Therefore, there is a theoretical 17.6%~22% power savings using common cathode technology over common anode technology.

• 1). Electricity, save operating costs: accurate power supply to reduce led display power loss, reduce operating costs.

• 2). No-cooling systems required: low heat temperature rise can also save the air conditioning, fans, and other cooling equipment.

• 3). Maintenance and repair costs: the subsequent fully enclosed die-casting aluminum chassis, the components are maintained one by one, making the led display life is about 2 times that of ordinary screens.

Ultra-low power consumption & temperature riseThe indoor common cathode LED screen can effectively save energy and dissipate heat through the flip-chip LED plus common cathode drive.

The Common Cathode Outdoor Fine Pitch LED Display series, with pixel pitches of 1.2mm, 1.5mm, 1.8mm, and 2.5mm, provides unmatched clarity and durability for outdoor environments. Utilizing cutting-edge common cathode technology, these displays significantly reduce power consumption and heat output, all while maintaining high brightness levels. This ensures reliable, long-lasting performance, even in the most demanding outdoor conditions. Whether for advertising, events, or architectural installations, these displays offer vibrant, high-definition visuals with exceptional stability.

The future of led displays is to be more energy-efficient and environmentally friendly and to provide high-performance and low-power products that can solve the customers’ problems. The LED display should also be easy to maintain so that it can work stably for a long time. The LED display production technology is becoming more mature, and the future development of LED displays will focus on meeting the personalized needs of customers with energy-saving and easy-maintenance features.

Contact us today to learn more about how our LED displays can enhance your outdoor projects and deliver exceptional visual impact.

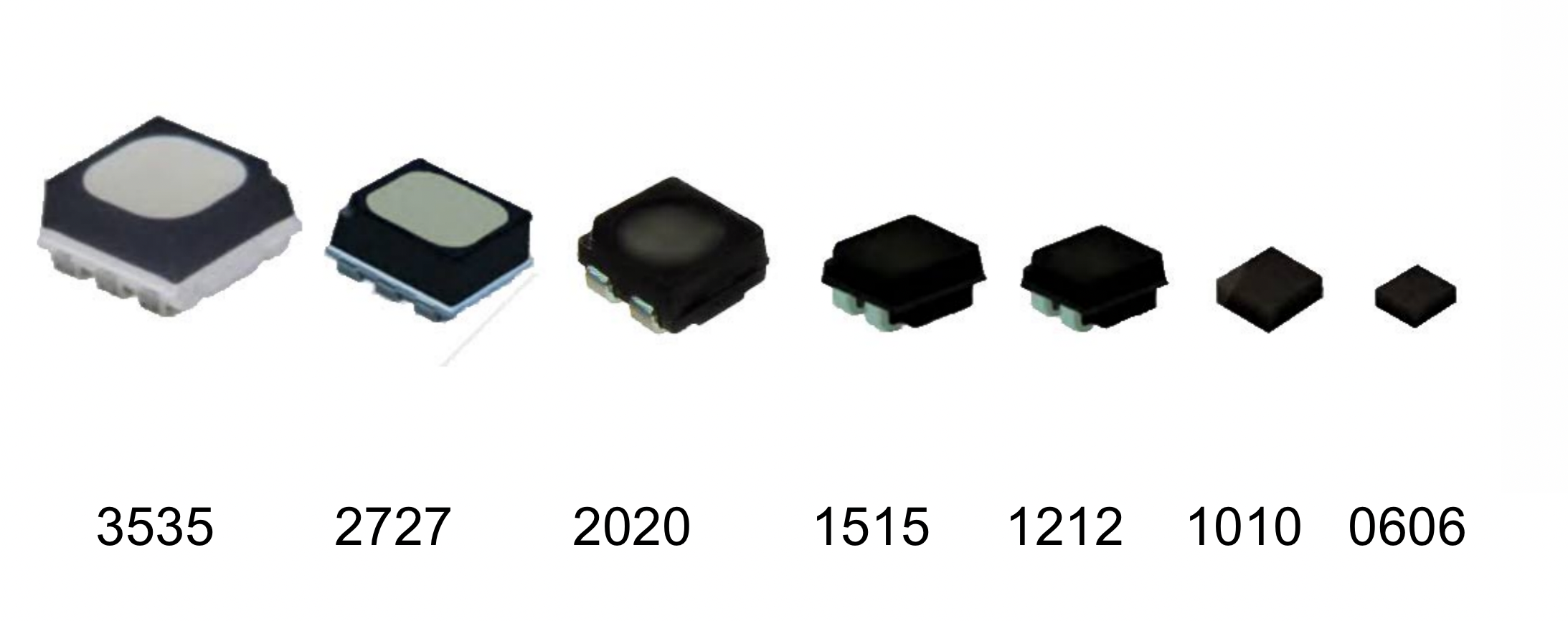

Advantages and disadvantages of SMD :

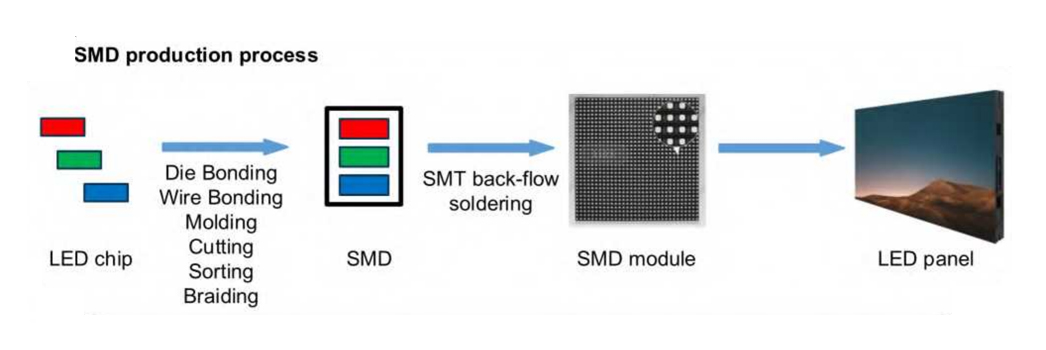

Introduced in 2001, SMD packaging technology is highly mature for 1mm and above products, whether for indoor or outdoor applications, with almost two decades of development. SMD has a well-established supply chain with complete equipment and experienced production lines for mass production. SMD diodes are highly reliable and easy to repair, and the cost is relatively low compared to other packaging methods.

SMD surfaces are not sealed like COB’s, therefore the level of protection against water, dust, and external force (during transportation and installation) is not as high as expected. This is why fine-pitch LED display installation becomes a white-glove job, requiring delicacy and experience. Some SMD LED displays use a module mask (shader). In high-temperature environments, mask bulging is likely to occur, which will affect viewing. In most cases, the mask surface may turn white or yellow after a period of use, which may also degrade the user experience. Pixel pitch at or below P0.7mm presents physical limitations. Due to the size of SMD packaging and welding wiring layout space on PCB boards, it is challenging for SMD displays to advance to finer pitches.

Definition of fine-pitch LED displays

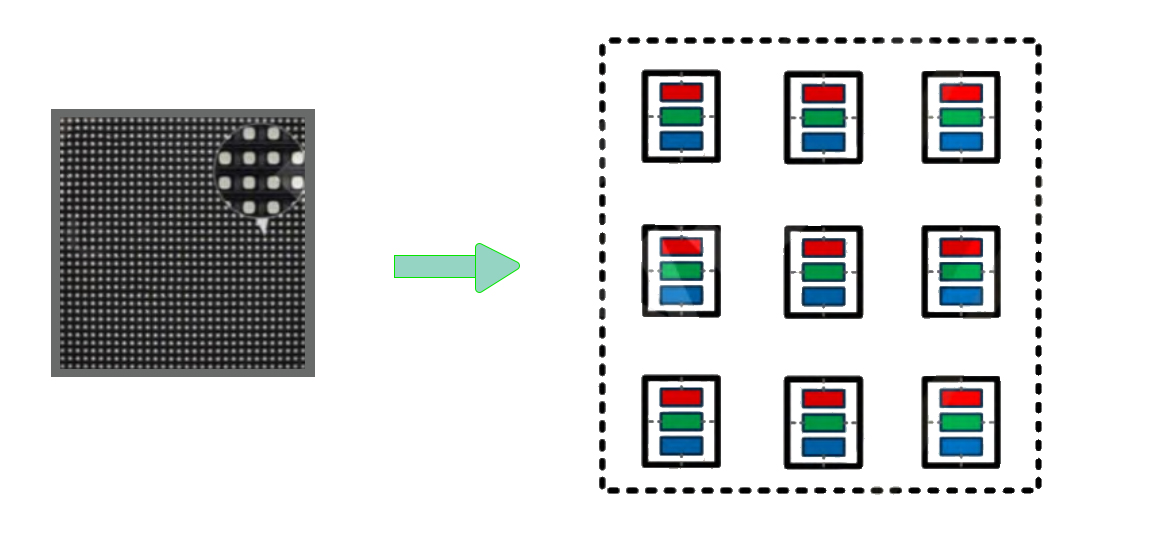

Fine-pitch LED display generally refers to LED displays with pixel pitch at or below 2.5mm. Mainstream fine-pitch LED display products are referred to as P2.5, P1.8, P1.5, P1.2, P0.9, etc. As technology develops and costs lower, direct-view fine-pitch LED displays are being used in an increasing number of applications, including corporate, retail, and educational settings, control rooms, broadcast studios, 3-D, and virtual or augmented reality displays. Compared with traditional larger-pitch LED displays, fine-pitch LED displays to bring higher resolution (full HD, 4K, 8K, and higher) to the application market, allowing an increasingly broader range of creativity. Fine-pitch LED display is a general term for a larger set of systems, consisting of LED display, HD/UHD display control systems, video processing systems, etc. Fine-pitch LED displays to use pixel-level point control technology to achieve a highly detailed level of brightness, color reproduction, and uniformity in every pixel unit. A key production link in the fine-pitch LED display manufacturing process is Automatic Reflow Welding, which helps to improve the reliability of welding and tremendously reduces the pixel failure rate.

Development history of fine-pitch LED displays

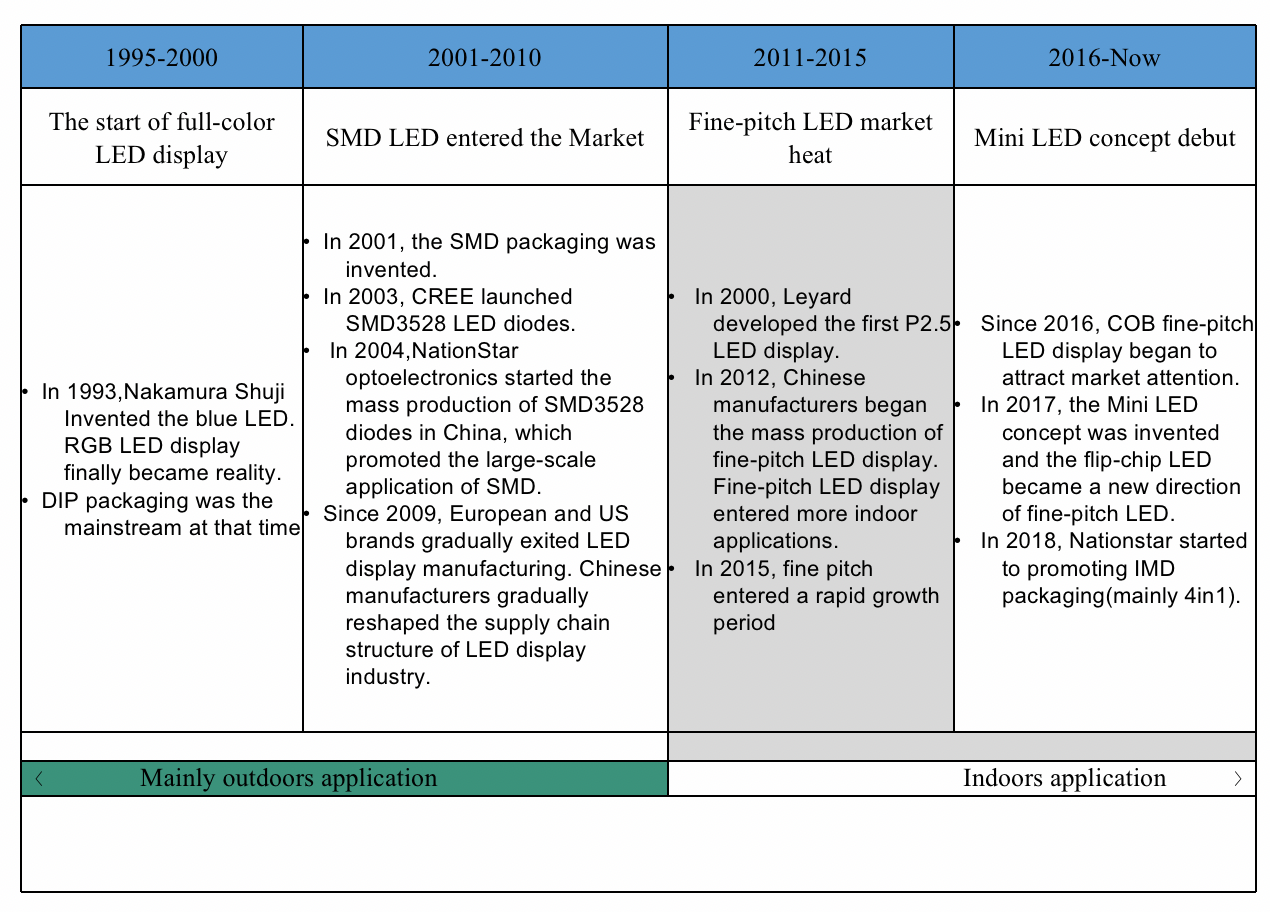

Since LED displays entered the application market, they have developed from single- and dual-color displays to full-color screens, then to fine-pitch. Prior to 1993, LED display screens were limited to red and green dual-color displays and were used in limited applications such as traffic lights and the banking & securities industry. In 1993, Nakamura Shuji invented the blue LED chip, which completed the three primary colors (RGB) and opened a new chapter of full-color displays. In 2001, SMD packaging was introduced, and Chinese LED display manufacturers gradually grew in scale and expanded from domestic to overseas markets. By 2009, European and American enterprises withdrew from the LED display manufacturing market, and Chinese manufacturers became a driving force in the global LED display industry.

In 2010, with the launch of the first P2.5mm fine-pitch display, the entire industry began a long-term evolution from outdoor to indoor applications, shifting from larger to finer pitches. The following five years witnessed a stunning 3-digit growth rate with fine-pitch products used in more and more applications. In 2015, facing pressure from Chinese LED display manufacturers, whose compound annual growth rate exceeded 100%, manufacturers of traditional rear-projection and LCD equipment, such as Samsung, Panasonic, Planar, NEC, etc, also joined the fine pitch race. In 2016, Sony-made COB products caught market attention, especially after its Crystal Micro-LED screen, based on COB packaging technology, exhibited at CES in 2017. In the same year, the concept of mini-LED was raised and COB packaging further advanced to flip-chip technology. In 2017, IMD (integrated matrix device, also known as N-in-one) technology was introduced by NationStar with its pioneering product, the 4-in-1 IMD0.9, dividing the fine-pitch market into three major product lines: SMD, IMD, and COB.

2020 was expected to be the beginning of the Sub-1 mm Era, with a conservative estimate of 5% of overall fine-pitch sales volume. However, due to the worldwide outbreak of COVID-19, the Sub-1 mm Era may be postponed into 2021 or even 2022.

VISIONPI provides a full range of fine pixel pitch led wall solutions from 0.77 to 2.5mm.Get answers about Pricing, Specifications, Installation, and more.