Solar Power LED Screen

The LED display we are introducing marks a significant advancement in renewable energy utilization and energy-efficient technology. This state-of-the-art display is powered entirely by solar energy, harnessing the sustainable power of the sun to operate with unparalleled efficiency. At the heart of this system lies our newly developed energy storage module, a testament to our commitment to innovation in the field of green technology.

What are solar powered LED display?

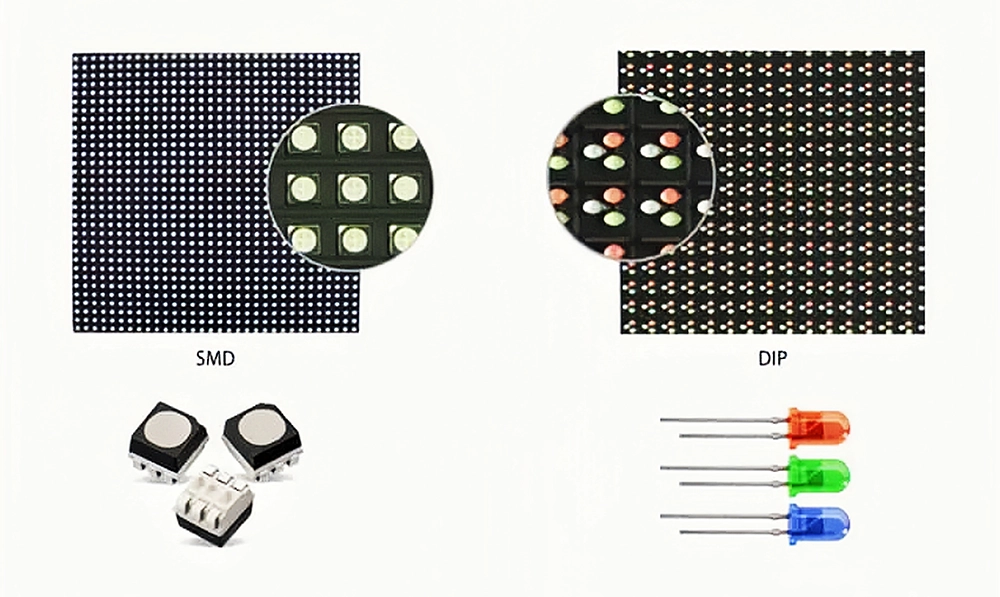

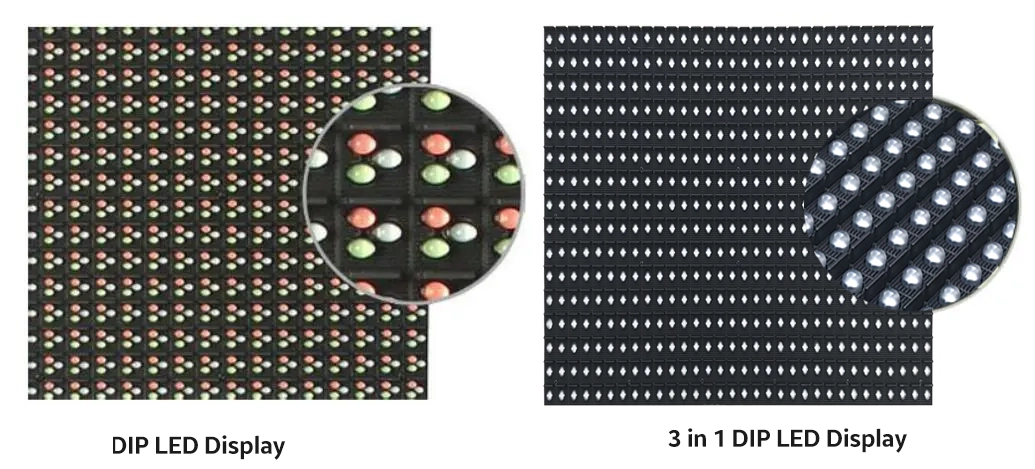

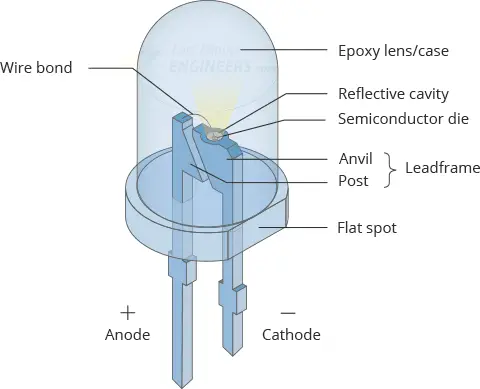

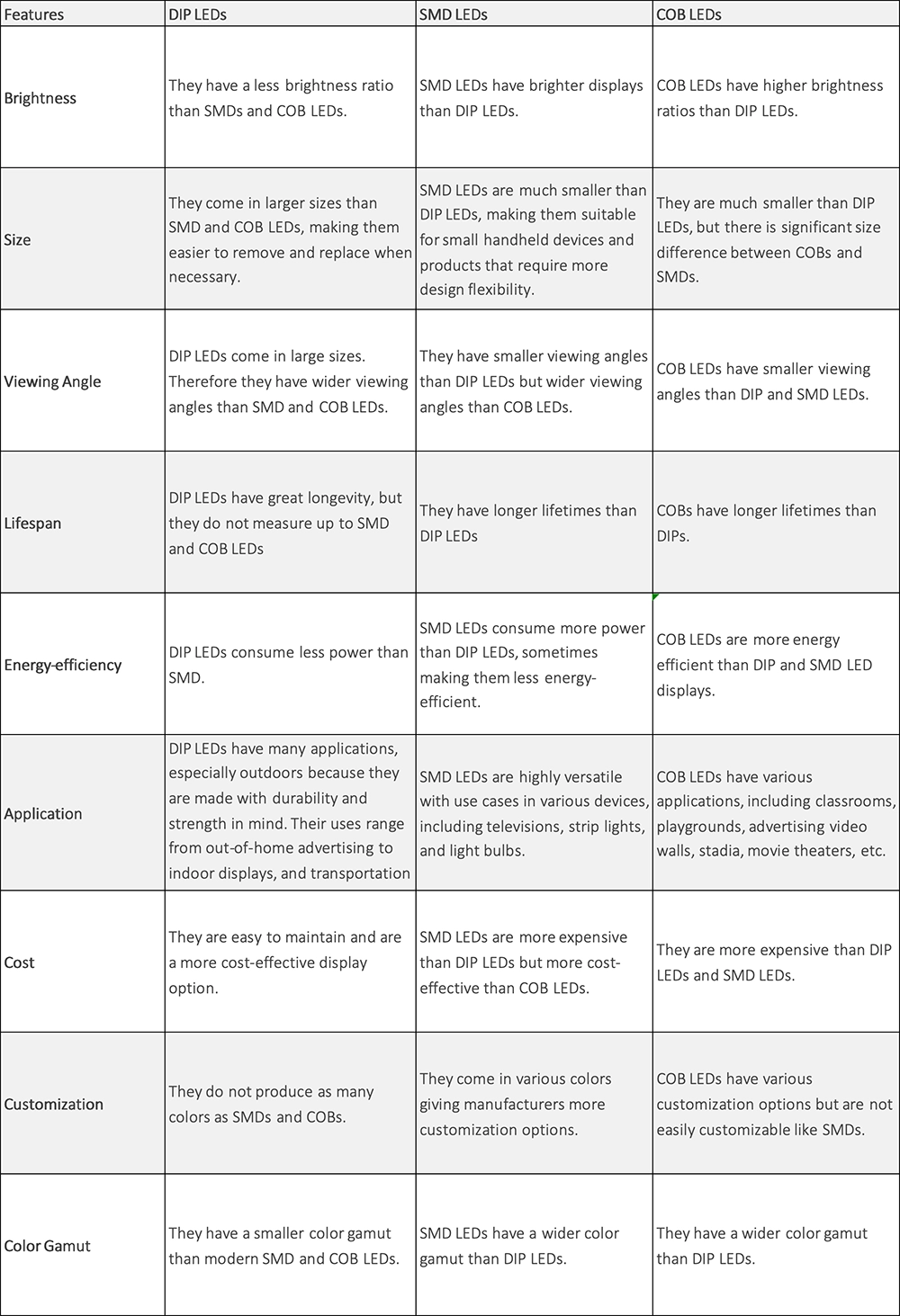

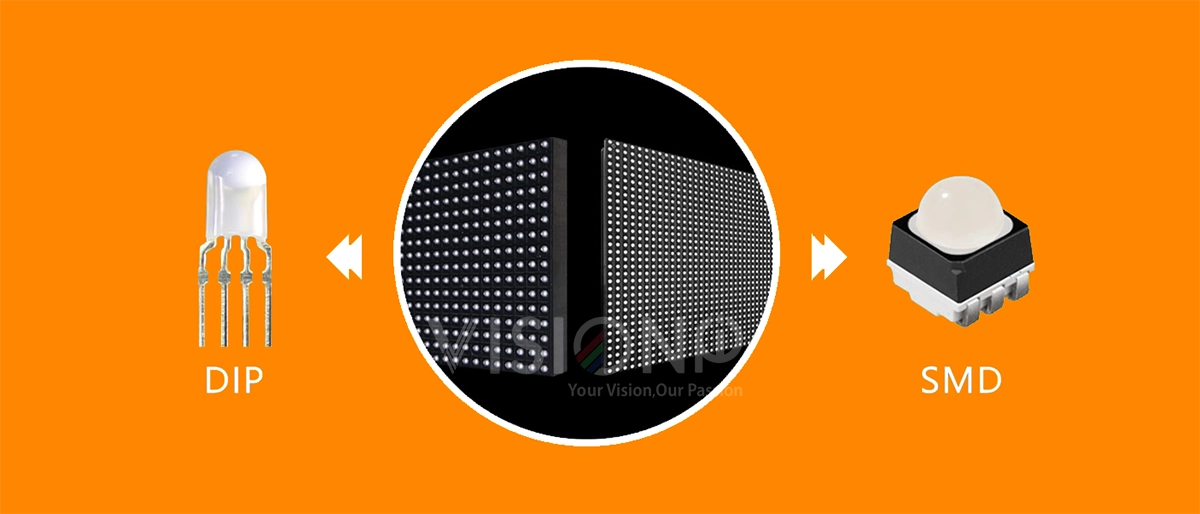

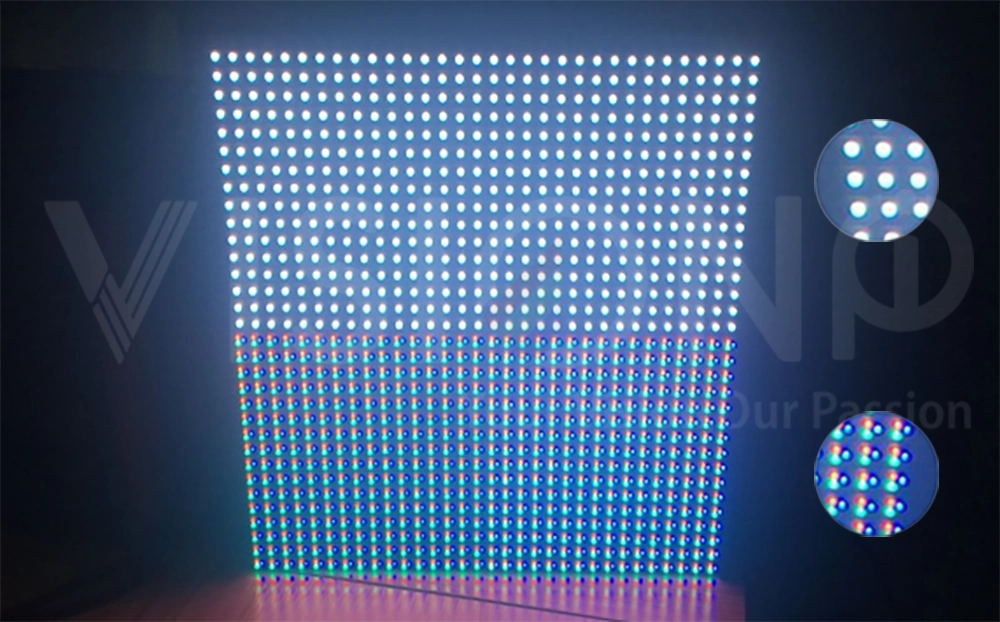

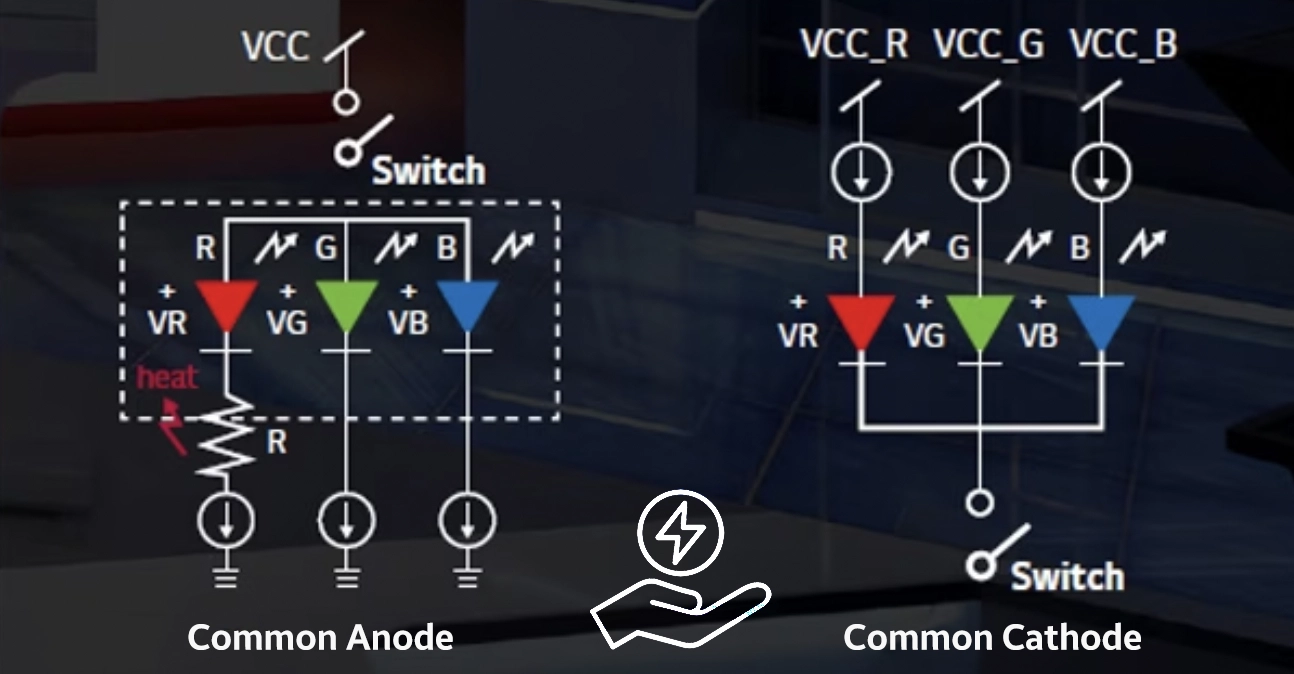

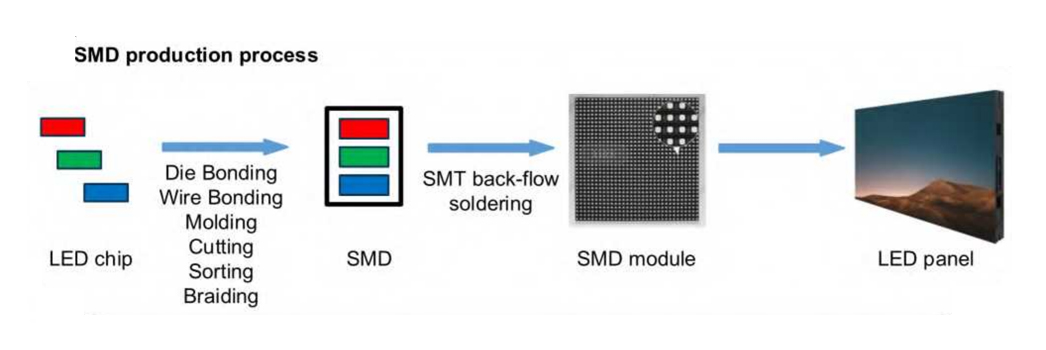

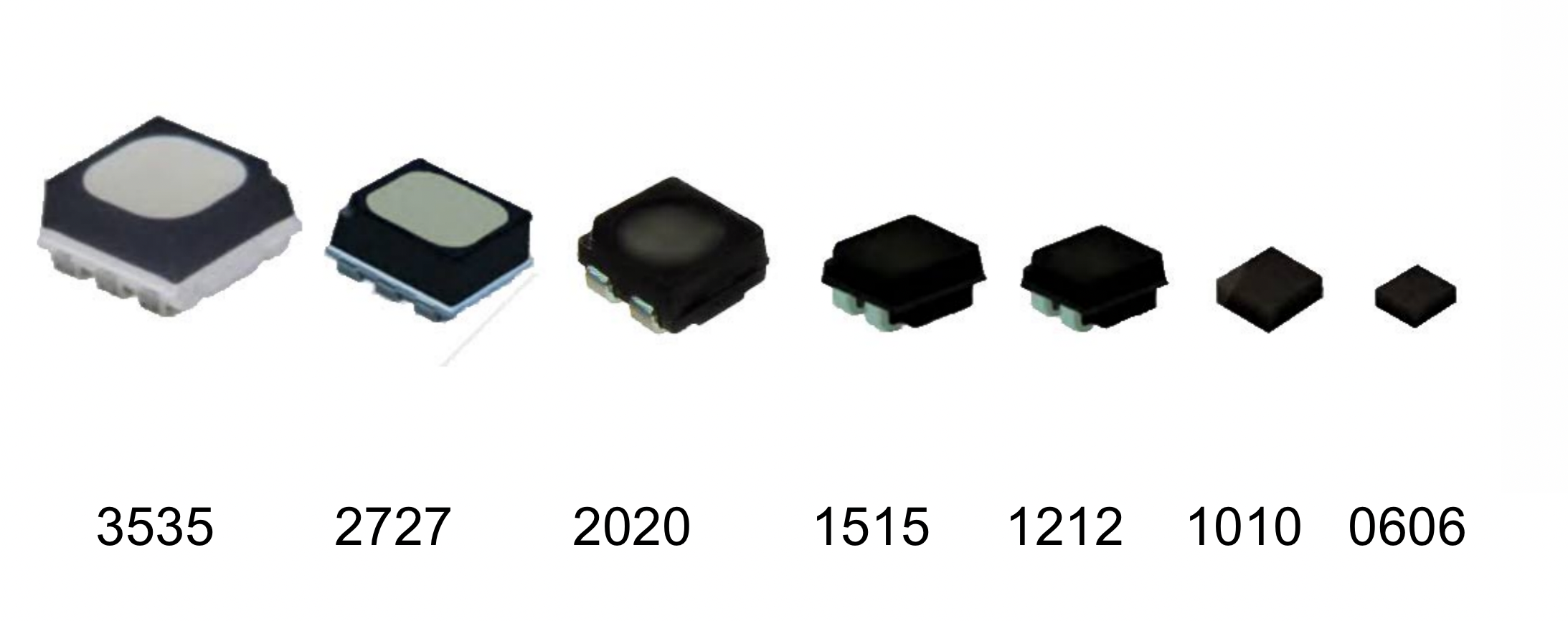

Solar-powered LED displays are electronic devices that use light-emitting diodes (LEDs) to show images, text, or videos. LEDs are small semiconductor components that emit light when an electric current passes through them. They are more energy-efficient, durable, and versatile than traditional incandescent or fluorescent bulbs.

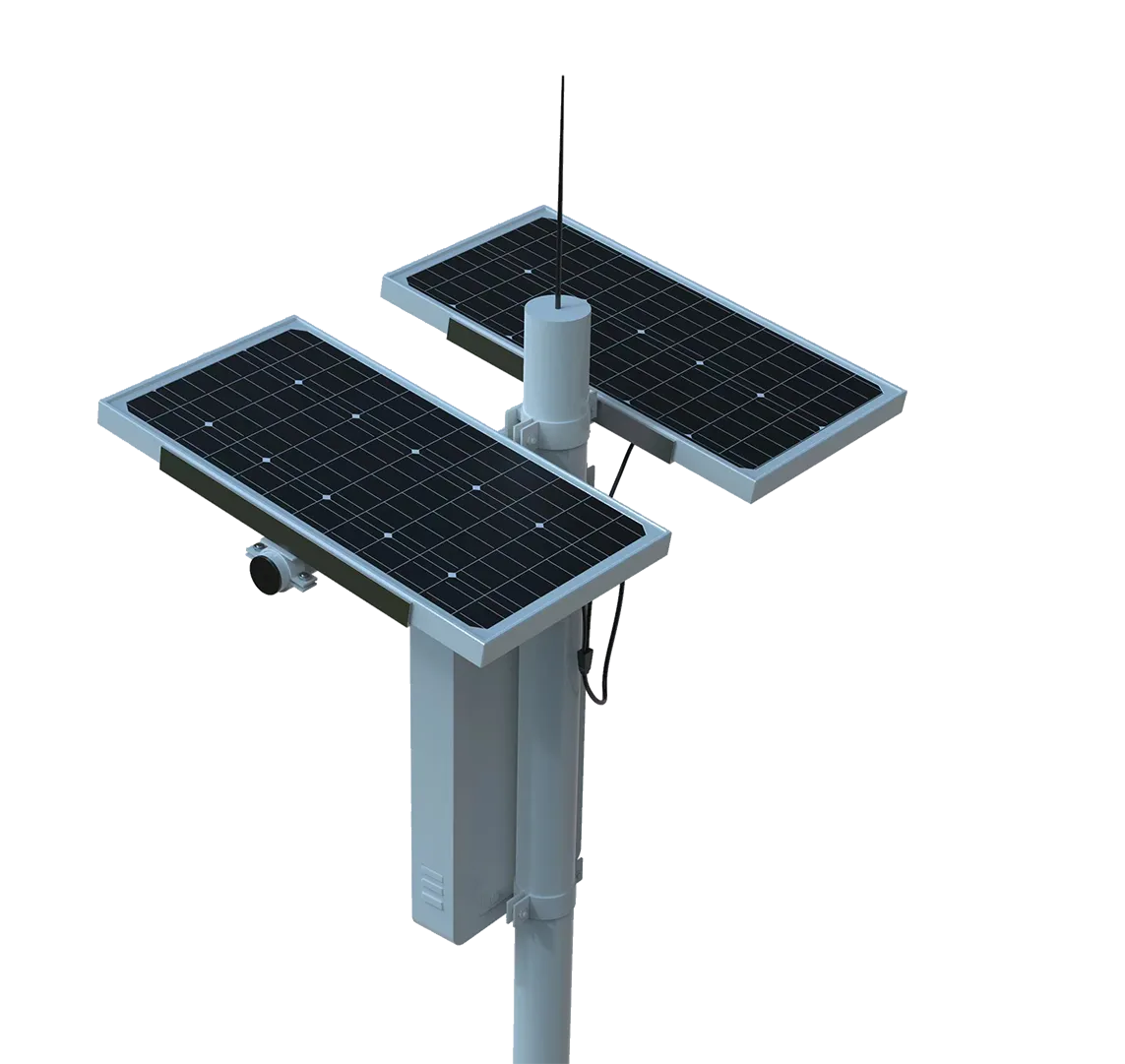

Solar-powered LED displays use photovoltaic (PV) panels to convert sunlight into electricity, which is then stored in batteries or capacitors. The stored electricity is used to power the LEDs and other components of the display, such as controllers, sensors, or speakers. Some solar-powered LED displays also have backup power sources, such as grid connections or generators, to ensure continuous operation in low-light or cloudy conditions.

How do solar-powered LED displays work?

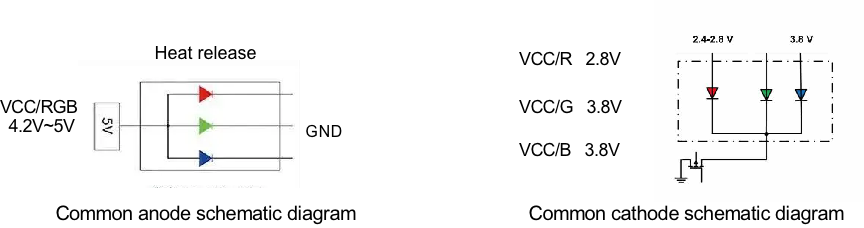

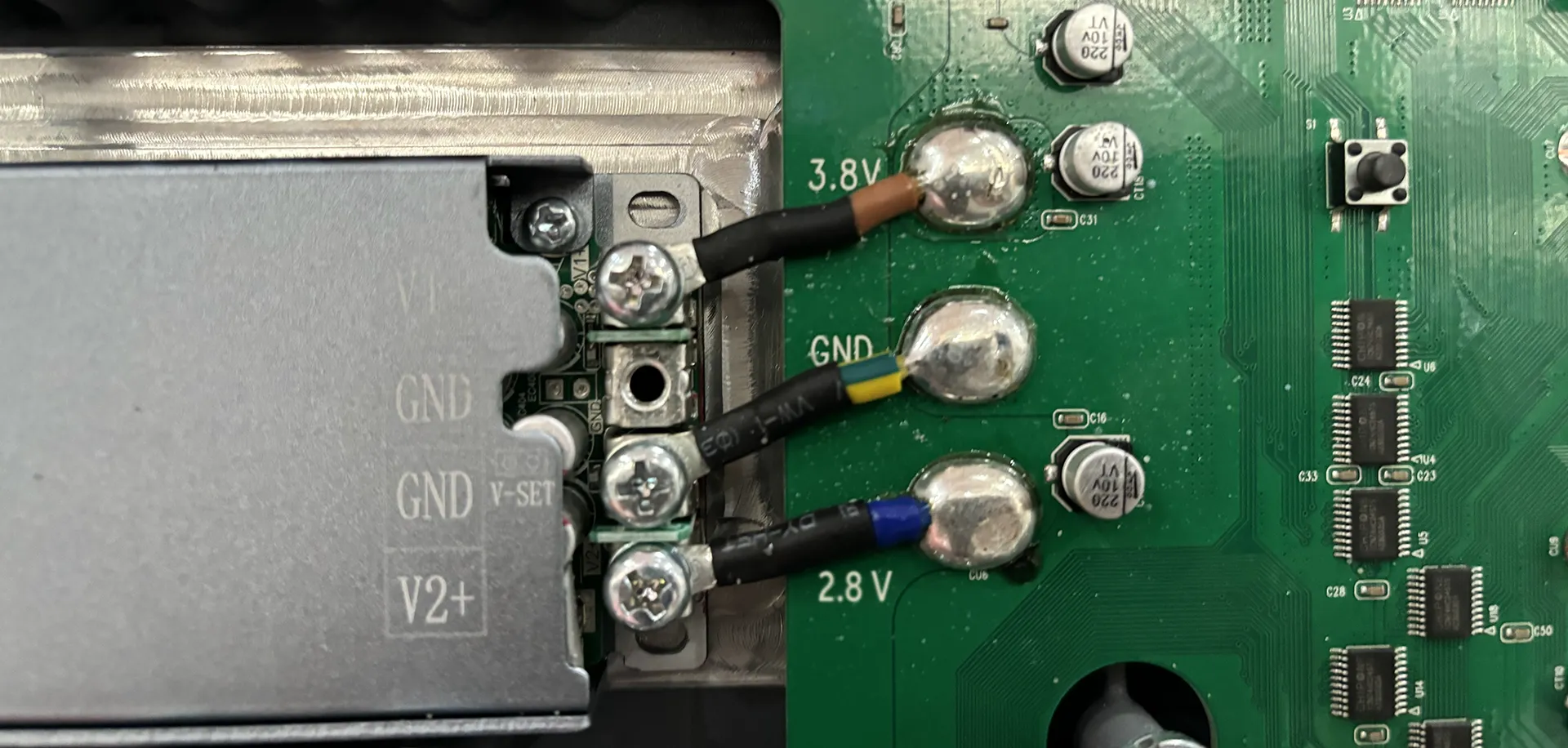

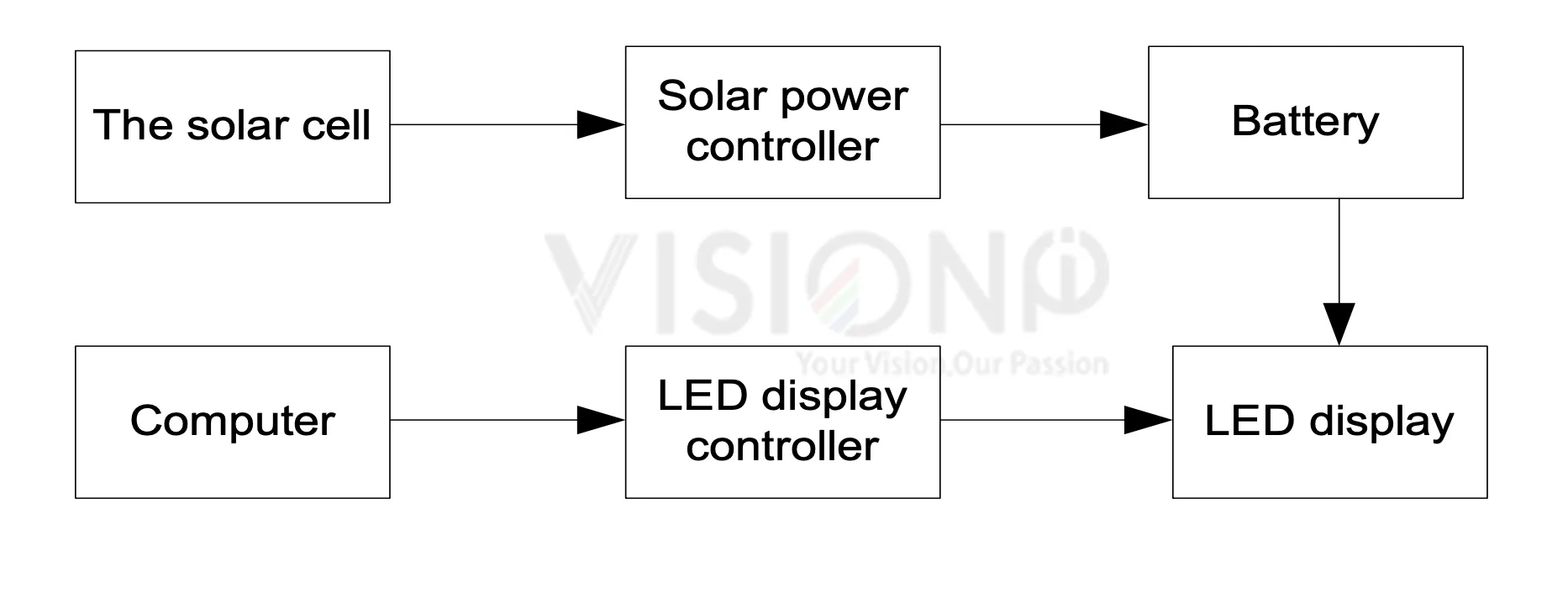

A solar-powered LED display consists of three parts: the solar control part, the battery part, and the LED display part. The solar control part is responsible for measuring the solar voltage, controlling the battery charging and discharging, and regulating the output voltage. The battery part stores the electrical energy converted from the solar panel. The LED display part shows the dynamic information from the video signal.

The solar controller is the key component of the system, as it affects the performance and service life of the battery and the LED display. The solar controller monitors the battery charge and discharge conditions and prevents overcharge or deep discharge. The solar controller also adjusts the output voltage according to the load demand and protects the system from short circuits or overloads.

The design of the solar controller includes the following aspects: solar voltage measurement, battery charging and discharging control, output voltage regulation, and system protection

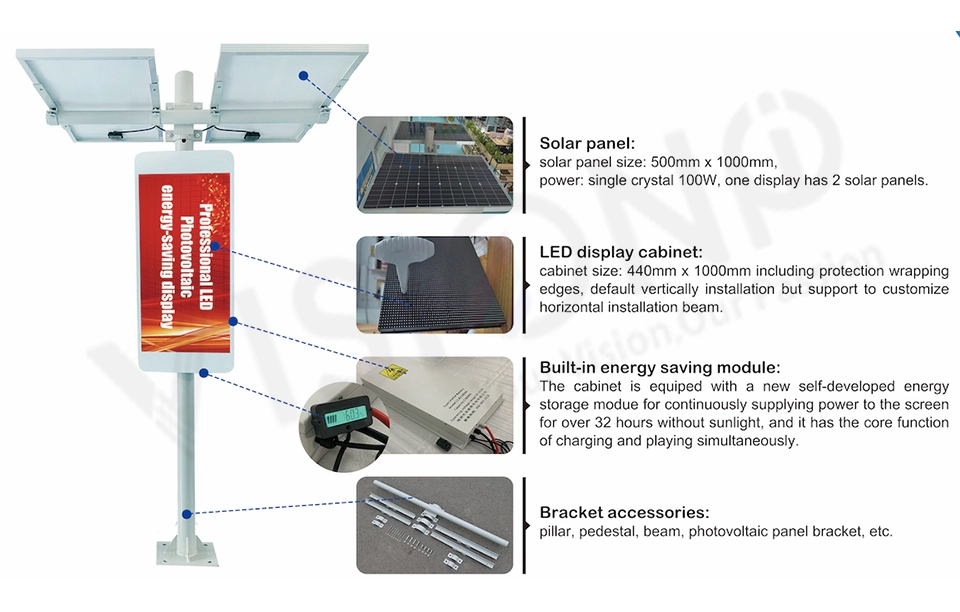

This cutting-edge module is designed to accumulate and store solar energy with exceptional efficiency, ensuring a reliable power supply to the LED display for over 32 hours in conditions devoid of sunlight. Such capability is pivotal for continuous operation, particularly in geographic areas with varying sunlight availability. The module’s sophisticated design enables it to charge during daylight hours while simultaneously powering the display, a feature we describe as “charging and playing synchronization.” This ensures that the display remains operational, showcasing vivid and dynamic content without interruption, regardless of the solar conditions.

What are the benefits of solar-powered LED displays?

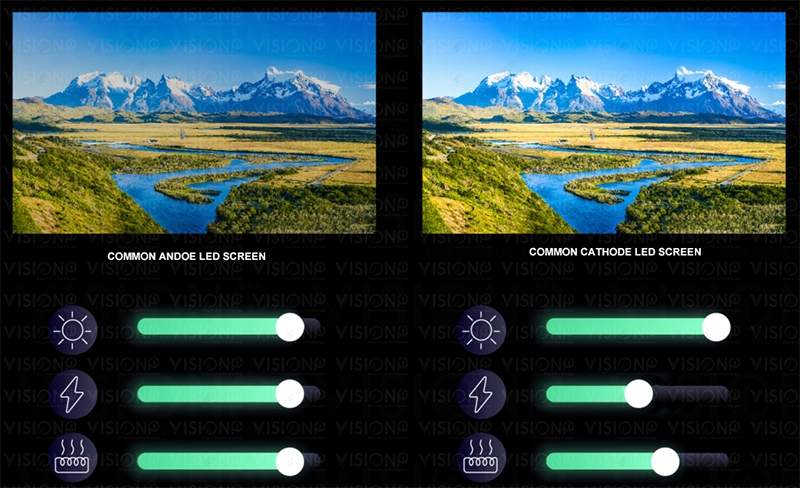

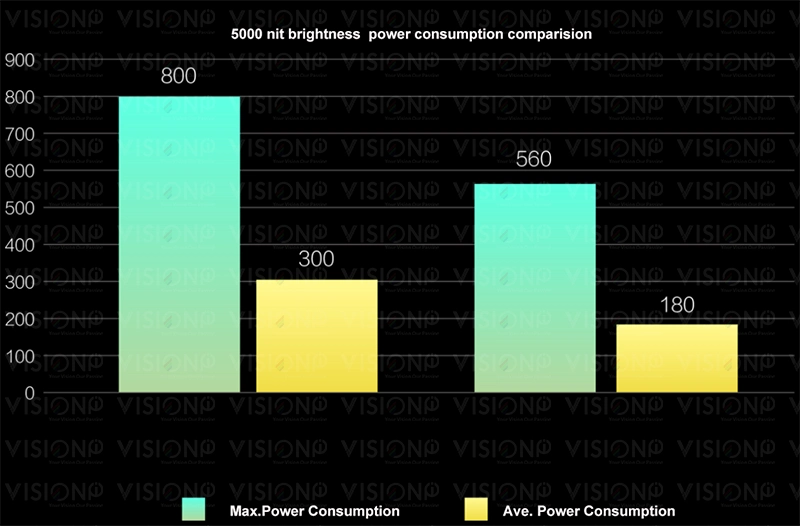

Solar-powered LED displays have many advantages over conventional displays that rely on grid electricity or fossil fuels. Some of the benefits are:

-

Environmentally friendly

. Solar-powered LED displays reduce greenhouse gas emissions and air pollution by using renewable energy sources instead of fossil fuels. They also reduce waste and resource consumption by having longer lifespans and lower maintenance costs than traditional displays.

-

Cost-effective

. Solar-powered LED displays have lower operating costs than conventional displays because they do not need to pay for electricity bills or fuel costs. They also have lower installation costs because they do not need complex wiring or infrastructure. They can pay for themselves in a few years by saving on energy expenses.

-

Unlimited Flexibility in Install Location

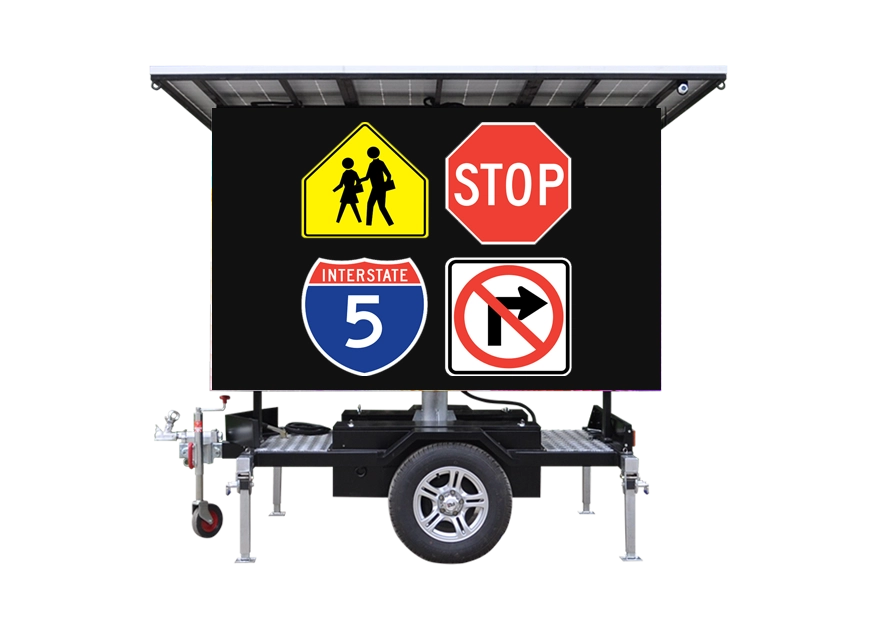

Solar-powered LED displays can be used for various applications, such as advertising, education, entertainment, information, security, or art. They can be installed in any location that receives adequate sunlight, such as rooftops, walls, windows, billboards, vehicles, or portable stands. They can also be customized in different shapes, sizes, colors, and resolutions to suit different needs and preferences.

-

Reliable

. Solar-powered LED displays can operate independently of the grid or other power sources, which makes them ideal for remote areas or emergency situations. They can also withstand harsh weather conditions and extreme temperatures better than conventional displays because they have no moving parts or fragile components.

Solar Power LED Display Applications

All countries of the world have adopted sustainable energy development strategies to protect the environment and ecology while using energy resources. Solar energy is a key area of development planning as a new energy industry. Solar photovoltaic is one of the fastest growing industries in the world, with an average annual growth rate of 40% in the last five years, surpassing the IT industry. As a clean and renewable energy source, solar energy generation is one of the most important directions for the world’s new energy development. The solar energy generation industry is rapidly emerging.

Electronic displays are widely used in various fields to show dynamic information. They can work both indoors and outdoors, and have many advantages over other display media. They can display text, images, and animations directly from video signals. Solar energy can power electronic displays, making them ideal for remote and inconvenient locations. Remote control can make them more convenient and timely. Solar energy also saves energy and protects the environment. This paper will design a solar-powered LED display based on the principle of electronic display screen.