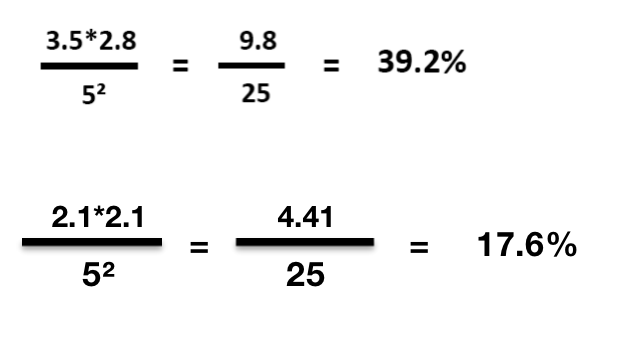

Fill Ratio-active VS inactive area As we briefly mentioned above, reflector cavities for LED packages come in several shapes, comprising greater or lesser percentages of active (light-emitting/reflecting) surface area of the package. The three most common shapes for these cavities are circular, rounded squares (similar to the shape of a radiant-cut diamond), and square. Since most of the industry uses an LED package referred to as a 35/28 SMD (which has a rectangular dimension of 3.5mm by 2.8mm) you can imagine which reflector cavity shapes allow for the highest active light regions within the package – square being the least and circular the most. The higher the fill ratio, the more lighted surface area. There is another component affecting this ratio as well. But some manufacturers will use 2121 for P5, which means the fill ratio will be only 17%, by using 2121 LED, They will save a lot of costs comparing with 3528 LED. Check the article “general SMD type for different pixel pitch led screens” to learn more about this topic. So which type of LED is reasonable to be used in different pixel pitches?

OUTDOOR:

>8mm ;10mm; 16 mm ——-3535 SMD

4.81 mm ;5mm ; 6mm ——2727 SMD

4.81 mm;5.95mm ————2525 SMD

2.6 mm–3.91 mm ————-1820 SMD

3mm;3.91 mm; 4mm ——– 1921 SMD

2.5mm-3mm———————1415 SMD

INDOOR:

2.5 mm -4 mm : 2020 /2121

SMD 1.875 mm-2.6mm :1515 SMD/1415 SMD

1.0-1.7mm : 1010 SMD

0.9mm– 0808 SMD

A lower fill rate can make the pixel pitch seem smaller without actually changing it, lighting area is smaller , it facilitates a better contrast ratio because there’s more black(black louver) visible against which the pixels can stand out. A higher fill rate on the other hand can make the pitch seem wider,The higher the fill ratio, the more lighted surface area ,while smaller black background. all else equal, and the larger a pixel is the more expensive it will be,the more brightness it will be.

Tops you may be interested

Industry news

Supply Chain

led Technology

Company News

LED Tips

White Paper

Quality Assurance

Manuels