LED Display Printed Circuit Board (PCB)

LED Circuit Boards(PCB)– the basement of the building. “LED Boards”, “LED blocks”, “LED panels”, “LED modules”, “LED cabinets” or simply “LED displays,” along with numerous other designations in the culture-specific parlance of the individual manufacturer, are in effect the biggest differentiated when comparing one SMD LED solution to another.

Choosing a Good Quality PCB

Choosing the right circuit board material for LED displays is crucial for ensuring their quality and reliability. Here’s a simplified breakdown of what to consider and some popular options to help you make an informed decision:

1. Heat Conductivity

LED displays generate a lot of heat. Selecting materials with good heat conductivity helps manage this heat, keeping the electronic components at a stable operating temperature and preventing overheating damage.

2. Electrical Performance

The electrical performance of the circuit board material affects the flow of current and voltage. Key parameters to look out for include electrical resistivity, dielectric constant, and dielectric loss. These factors ensure smooth current flow and stable signal transmission.

3. Mechanical Strength

LED displays need to withstand mechanical stresses such as vibrations, impacts, and bending. Materials with high mechanical strength ensure the display’s structural stability and reliability.

4. Environmental Friendliness

With growing environmental awareness, choosing eco-friendly materials is becoming important. Avoiding harmful substances like lead and halogen compounds is crucial for both environmental and health safety. Look for materials compliant with environmental standards like RoHS.

Why Multiple Layers for LED Display

PCB, or Printed Circuit Board, layers are essentially the various levels or strata through which electrical connections are made in a circuit board. Think of a PCB like a multi-story building, where each floor represents a different layer with its own specific function, and stairs or elevators (vias in PCB terms) connect them together.

These layers house power circuitry and electrical grounding. Also, electronic circuitry to deliver, drive, and distribute both data for rendering the digital content and electricity to power the LED (Light Emitting Diode) will be housed in these layers. With respect to the “pixels” – the individual RGB LED packages – there are circuitry, diodes, resins, design elements, and peripheral surfacing materials/colors to consider as well.

- Layer 1 (Top Layer): This contains the components like resistors, capacitors, and integrated circuits. It’s connected by copper traces that form the circuit.

- Layer 2 (Inner Layer 1): Dedicated to ground connections. This layer helps in reducing electronic noise and interference, providing a stable environment for the circuit to function.

- Layer 3 (Inner Layer 2): Used for power distribution. This layer distributes power from the power supply to various components across the board.

- Layer 4 (Bottom Layer): It may contain additional components or traces that couldn’t fit on the top layer, or it could be used to complete circuits that start and end on the top layer.

How Many Layers of PCB for LED Display

For LED display PCBs, the number of layers required can vary significantly depending on the complexity, power requirements, and size of the display. Generally, LED displays can be categorized into simpler designs, such as those used in small consumer electronics, and more complex arrangements, like those seen in large outdoor or high-resolution displays. Here’s a general guideline:

Big Pixel pitch LED Displays

1 to 2 Layers :Simple (big pixel pitch) LED displays, such as those used in outdoor advertising P10,P8 or the single color led banners often use 1 or 2-layer PCBs. These are sufficient for routing power and signals to a modest number of LEDs without complex circuitry.

Moderate Complexity LED Displays

2 to 4 Layers: As the complexity increases(high brightness,high refresh rate) with more LEDs and driving IC or the need for better power distribution and signal integrity, PCBs may expand to 2 to 4 layers. This allows for more sophisticated routing that can accommodate moderate densities of LEDs, improved heat management, and reduced electromagnetic interference (EMI).

High-Complexity LED Displays

4 Layers and Above: Large-scale or high-resolution indoor and outdoor LED displays, such as those used in outdoor advertising, stadiums, or professional-grade indoor displays, require 4 layers or more. These displays need extensive routing for hundreds to thousands of LEDs, necessitate excellent thermal management, and must minimize EMI. High-layer-count PCBs offer the necessary space for intricate routing and dedicated layers for power and ground planes, which enhances the overall performance and reliability of the display.

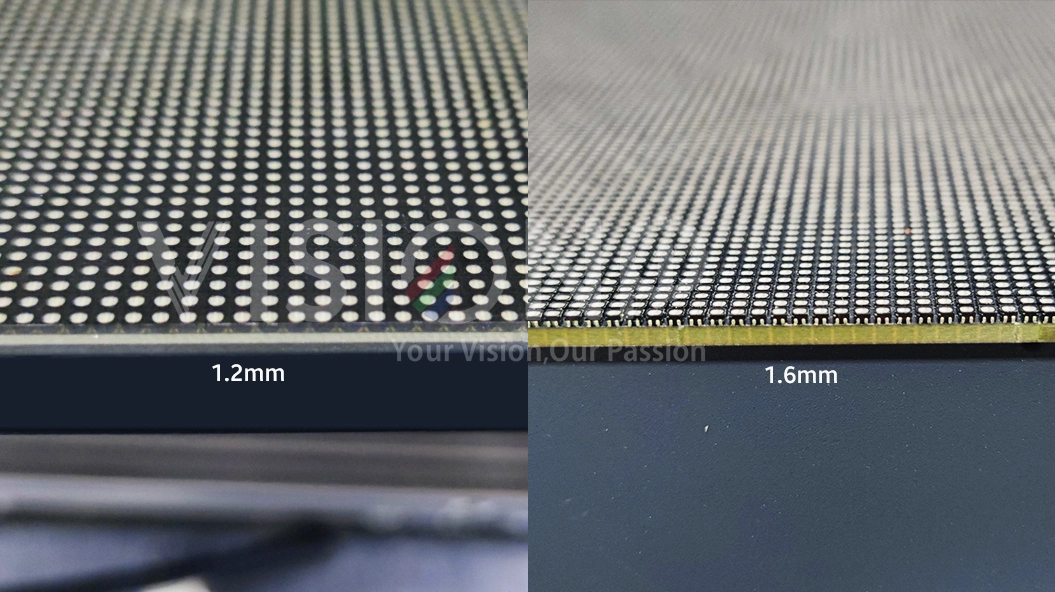

Material requirements: PCB board thickness:

The base material of most PCBs is a copper clad laminate consisting of fiberglass reinforced epoxy resin. Standard thicknesses for common laminate grades are:

- 0.8 mm

- 1.0 mm

- 1.2 mm

- 1.6 mm

Thinner laminates are more prone to warpage while thicker stacks can resist flexing and twisting forces.

generally 1.6mm thickness; Material: FR-4 glass fiberboard, some manufacturers may use FR-2 paper substrate in order to reduce costs.

Copper foil thickness:

The thickness of the copper foil is the key to heat dissipation of the PCB board and the stability of the circuit. The normal copper foil thickness is 35um (1Oz), while one manufacturer will use the 18um (0.5Oz) copper foil. How can tell which standard they are making ? by weighting an empty, you can find out which is better, Under normal circumstances, the heavier the better.

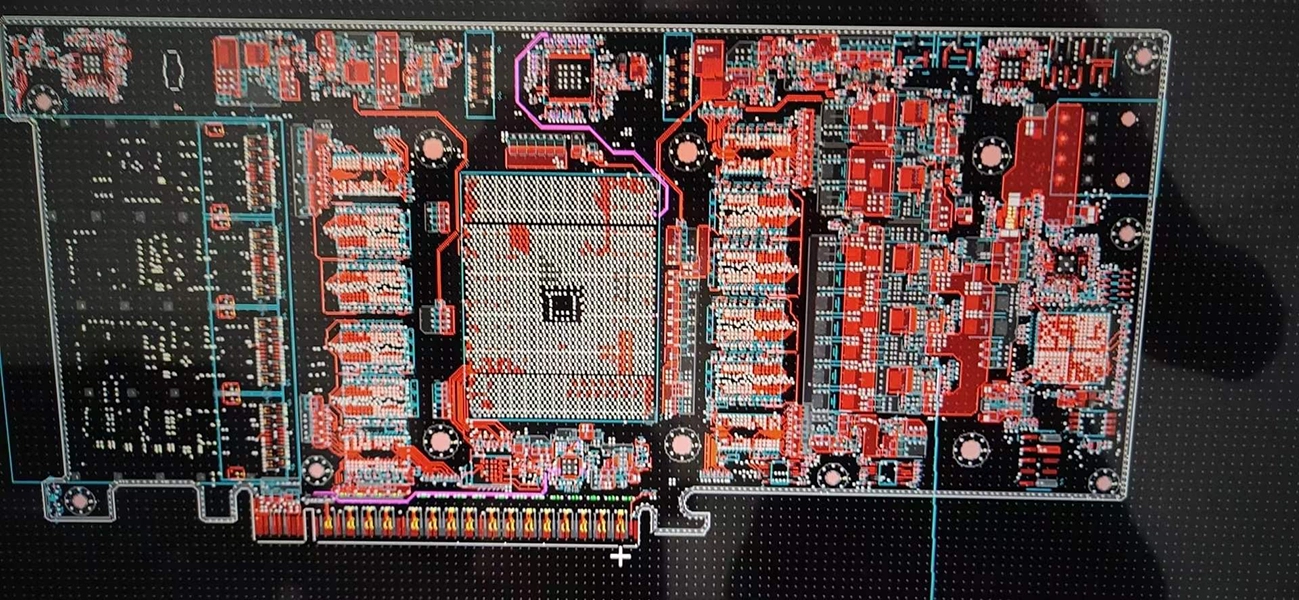

Circuit Design:

The designs of the actual circuitry to deliver data and power to the diodes are as different and recognizable in the LED display manufacturing industry as the brush strokes of Monet and Lautrec are in French Impressionism. This is where the real intellectual property of the individual manufacturers of these displays begins to differentiate the products.

The end game of these designs is to maximize the conversion of electrical wattage to light vis-à-vis heat. More light, less heat wins the race. Industry standards show that current typical circuitry design renders somewhere in the 60%-75% range as the percentage of wattage converted to light in the displays. This means the remaining 40%-25% of wattage is converted to heat. Depending on the environment where the display solution will be used that could be a problem. Imagine LED displays emitting a high level of heat in a high-end retail cosmetics store adjacent to say a lipstick PoP structure. A manufacturer who’s the elegance of design with their circuitry is rendering conversion percentages approaching 85% to-light efficiency.PoP structure. There is a handful of tier 1 (read: high-quality) display manufacturers who are the elegance of design with their circuitry, is rendering conversion percentages approaching 85% to-light efficiency.

How to check the PCB Design?

The distance between the “road” should be at least triple of the thickness of the “road”, the easiest way is to send to visionpi to check. we provide service to check the design. if you are interested to know more check our another article” what makes a good PCB layout design.

Industry standards show that current typical circuitry design renders somewhere in the 60%-75% range as the percentage of wattage converted to light in the displays. This means the remaining 40%-25% of wattage is converted to heat. Depending on the environment where the display solution will be used that could be a problem. Imagine LED displays emitting a high level of heat in a high-end retail cosmetics store adjacent to say a lipstick