- Level 1: the recently-created and unstructured workshop; and the factories only make the assembly work with all the half-completed product purchased from other suppliers, there are thousands of factories like this.

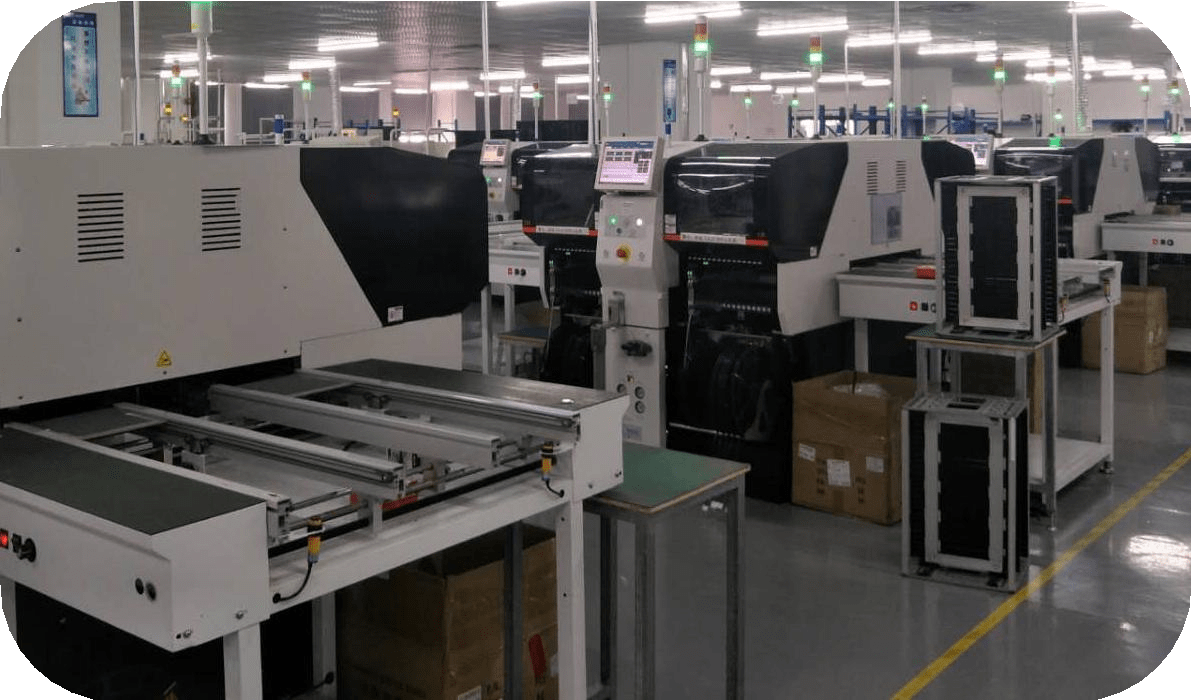

- Level 2: the semi-organized factory that got out of level 1 but is still struggling to keep quality & timing under control, they have SMT machines, they can produce led panels themself, and focus on the segmented market, like led poster, rental display, transparent.

- Level 3: the factory that made big efforts to get organized, with the objective of pleasing large customers, and they usually with many years of experience and their own R&D team and overseas sales team. here we can name a few, chip show, GCL, SBC.Yestech.

- Level 4: that rare birds like Yaham, Unilumin that applies Lean manufacturing, and that avoids level 3’s rigidity.

In this article, I am excluding Chinese state-owned enterprises, which are a breed on their own.

Most manufacturers are at level 1 or level 2:

Level 1: the unstructured led display workshop

Typical profile:

- 0-50 workers, engaged in simple processing (often assembly);

- Managed by the owner and his family;

- Not mature quality system and quality control staff;

- No ability or time to work on complex prototypes before production starts;

- Focused only on “making production” fast and on the cheap;

- Can accept small orders, as long as purchasing components in small quantity is possible;

- Seldom works directly for export customers;

- Count on other manufacturers or trading companies to get business.

Result: low costs and low MOQs, but needs to be followed very closely by customers.

Level 2: the semi-organized led display manufacturer

This category is a mixed bag. Some export 100% of their output and are very familiar with their market’s quality & safety standards. Others focus more on the domestic market or the most price-sensitive countries (Middle East, India…), and should be avoided by importers from North America and Europe.

Still, it is possible to draw a somewhat typical profile:

- 50-100 workers

- Has grown out of the “disorganized workshop” stage

- Has had to hire a few professional managers because of the growing complexity of operations

- Has had to hire a few QC employees, to avoid big disasters.

- But still, low concern for quality among staff and managers (in most cases).

- May have English-speaking salespeople if direct relationships with foreign customers is a goal.

- May still get orders mostly from trading companies and other factories.

Result: costs are relatively low, and quality & timing are relatively unstable. The owner’s motivation for your orders still determines their reliability.

Level 3: the organized/Listed led screen manufacturer

Typical profile: 200+ workers, usually established before 2010 with decade experience.

They have tried hard to comply with demanding buyers’ requirements:

- Every aspect of production is specified in detail;

- Production is checked thoroughly by QC department;

- Own R&D team and updating led

- Hopefully, strong staff discipline to follow the system;

- a team for export business,and 60-80% of their sales is come from exporting.

Result: few quality issues, but high indirect labor costs (QC, middle management) and low flexibility. Top 10 led sign board manufacturers

Level 4: the continuously improving led display manufacturer

Typical profiles:

- Part of a large multinational group or a joint venture.

- Midsize factory with a process-oriented/engineering-oriented general manager.

- dedicated to segment markets, like transparent led display or soft led display.

They follow the lean model:

- Regular improvements to material flow and to each process;

- Errors are prevented or corrected at the source;

- Staff is trained and supports the philosophy.

Result: high customer satisfaction (close to zero defects; production cycle below 5 days) and relatively low cost (high productivity of operators, limited QC staff, and rework).

Unfortunately, these companies are a very small minority. They usually don’t advertise themselves on B2B directories. They are very hard to find.

What kind of Chinese factories should you work with?

First, a couple of rules to keep in mind:

- If you work with a supplier that is too large relative to your orders (e.g. you would occupy 1% of their annual capacity), you will be quoted high prices and given poor service.

- If you work with a small supplier that cannot produce the quantities you order, they will be forced to subcontract production and you will probably be in for a disaster.

My general advice would be as follows:

- If your orders are very small, you might need to work with a trading company/quality assurance team that will place your orders in a level 1 factory and follow production.

- If your orders are large enough to work directly with a manufacturer, but not big enough to be interesting to big factories, go for level 2, but you will still need a final inspection service before the shipment to make sure everything settled.

- If your order is considered large and even big companies actively fight for your business, go for level 3.

- If you are in a very quality-sensitive market and you cannot afford even 1% of defects, spend time and search for level 4 (but you might not find any in your vertical).

Small importers tend to have the feeling that buying from a large factory is more expensive but more reassuring. There is some truth regarding the higher prices, but risks are not necessarily lower. the fierce competition makes the industry more of chaos. after all, the company needs to survive, if the price allows them little profit, they will have to find a way to saving the cost from the raw material. smaller companies who dedicated one or few product line can be a good one to work with.

We believe the core comptiveness is on the supply chain managment of a whole supply chain not between companies. VISIONPI dedicated in the supply chain management since the very beginning of the led display industry,back to 2000. we works with hundreds to thousand of importers to make the full adavantage of the supply chain in china.our professionla quality control team and managing system allow us to take the most advantage of the supply chain to provide our cusotmer with the best products.

What do you think?