Features Of COB LED DISPLAY

1. With Ultra-High Reliability

COB technology eliminates the process flow of SMD light-emitting tube packaging, color separation, taping, and patching, simplifies and improves the reliability of the product production process. Longer Life Span: Without the holder, the LED chip has lower heat resistance, largely increasing its life span

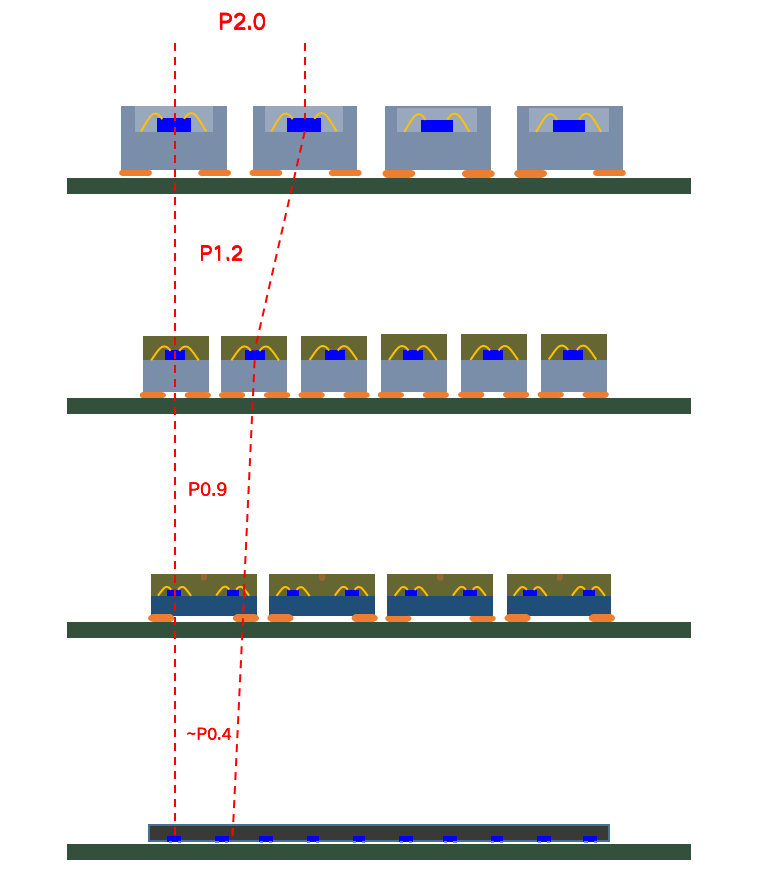

2. Smaller Pixel Pitch allowed

Smaller Pixel Pitch: the pitch of SMD is P1.2-P2.0, while COB is P 0.5-P2.0 .The COB technology is not limited by the physical size, bracket, and lead of the SMD LED package, and can break through the SMD pitch limit, achieve higher pixel density, and have a more flexible dot pitch design.

3. Larger Viewing Angle:

COB more likes the surface light source than the SMD, when light refracts, it has less light loss. COB Realizes The Conversion From “Point” Light Source To “Surface” Light Source.No pixel graininess; can effectively control the brightness of the pixel center, reduce the intensity of light radiation, inhibit moiré, glare, and glare to the retina, suitable for close and long-term viewing, not easy to cause visual fatigue, suitable for close-screen viewing.

4. Higher Protective Performance

The PCB circuit board, crystal particles, solder feet, and leads are fully sealed. The advantages of the sealed structure are an obvious-for examples, moisture resistance, anti-collision, prevention of pollution damage, and easier cleaning of the device surface.

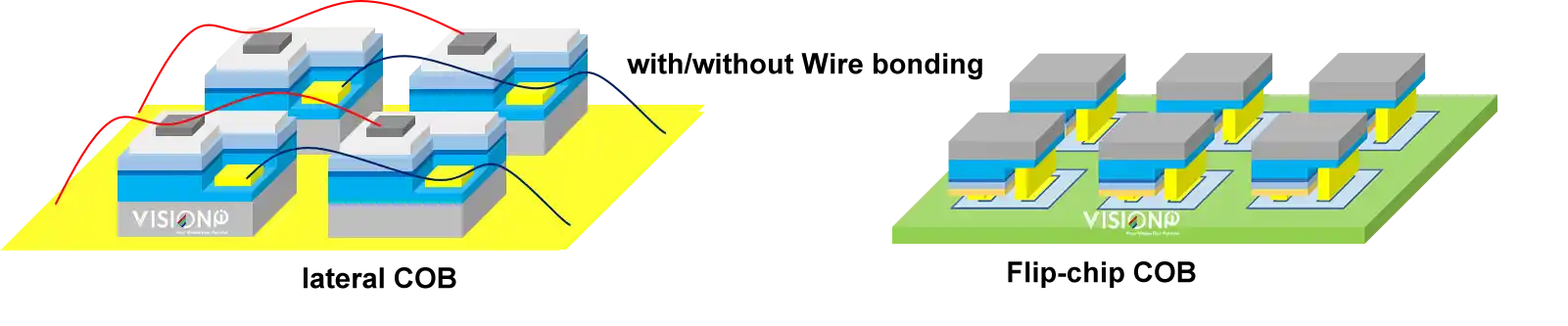

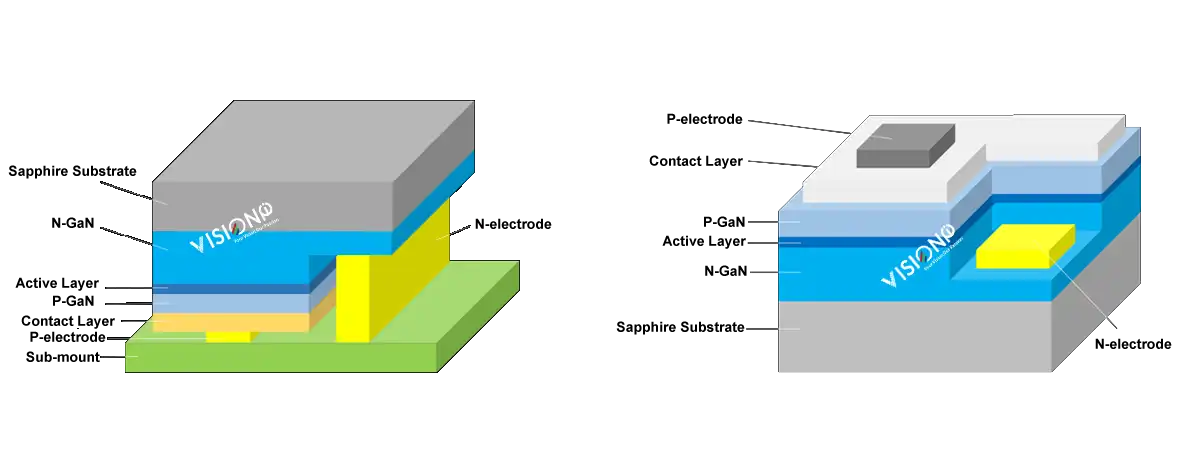

Wire bonding COB structure VS A Flip-Chip COB structure

Wire Bonding COB. In wire bonding COB Also called (face-up cob or Lateral COB), the LED chips are attached directly to the substrate using an adhesive, and their electrical connections are made with thin wire leads. This method is quite traditional and widely used due to its cost-effectiveness and simplicity in connecting the LED chips to the driving electronics.

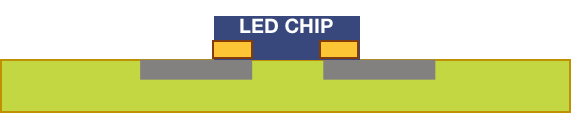

Flip chip COB, on the other hand, involves mounting the LED chip upside down on the substrate so that the light emits from the top, making direct contact with the substrate. This setup enhances heat dissipation, reduces the thermal path, and generally provides better luminous efficiency and reliability.

Flip chip cob led display advantages

1. Higher stability. Flip chip packaging technology eliminates wire bonding, eliminating the risk of gold wire breakage and simplifying the production process.

2. Smaller pixel pitch. Flip-Chip COB encapsulation is the chip-level integrated encapsulation. Without the wire bonding, the physical space size is only limited by the size of the light-emitting chip, which can achieve higher pixel density.

3. Better visual performance. Regarding display performance, the area of the Flip-Chip is smaller on the PCB board, and the duty cycle of the substrate is increased. It has a larger light-emitting area, which can present a darker black field, higher brightness, and higher contrast Presenting HDR-level display effects.

4. Cost-effective. There is no welding wire link, simplifying the production process and reducing equipment investment costs. As the industry scales, the product cost will be significantly reduced, especially when the dot pitch is less than 1.0mm.

Therefore, Flip-Chip COB technology is a necessary condition for the realization of MicroLED and will go further in the era of micro-display.

The Future Of direct view led display.

Flip-chip COB is an upgraded version of lateral COB, flip-chip COB improves reliability and visual performance, simplifies the production process, and narrows the pixel pitch. COB is the future of direct view led display

Well I truly enjoyed studying it. This subject procured by you is very helpful for proper planning.