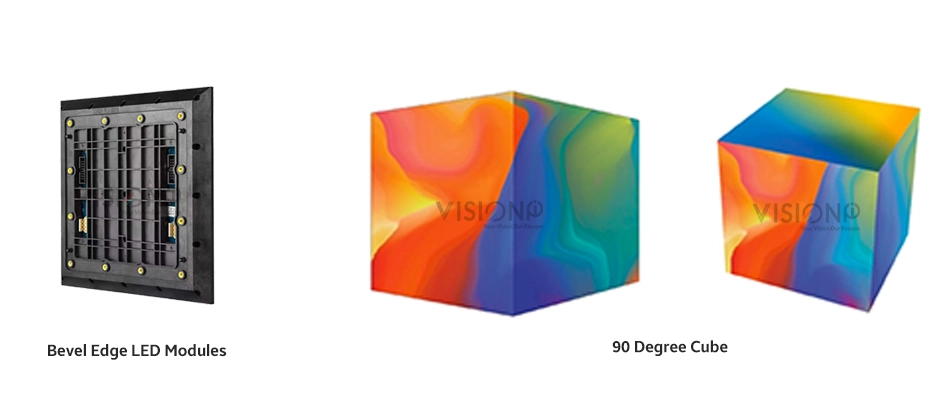

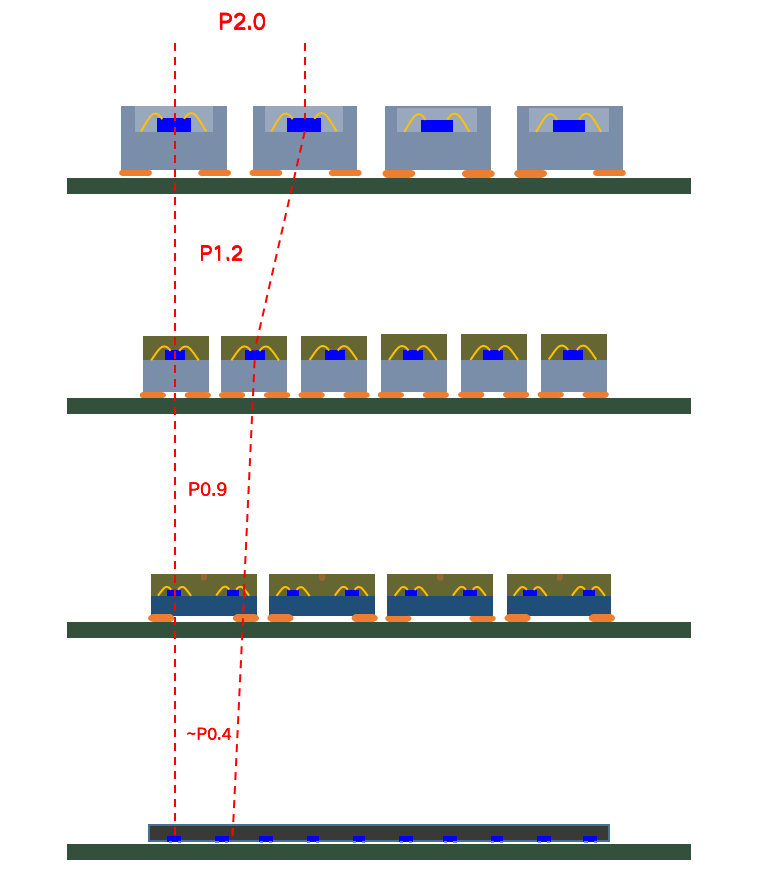

In the field of LED display, with the development of upstream packaging technology, there gradually form two different LED display panel preparation technologies, SMD ;IMD; COB. We can use these two technologies to produce small-spacing mini LED display screens. And we will share some information about these two technologies with you.

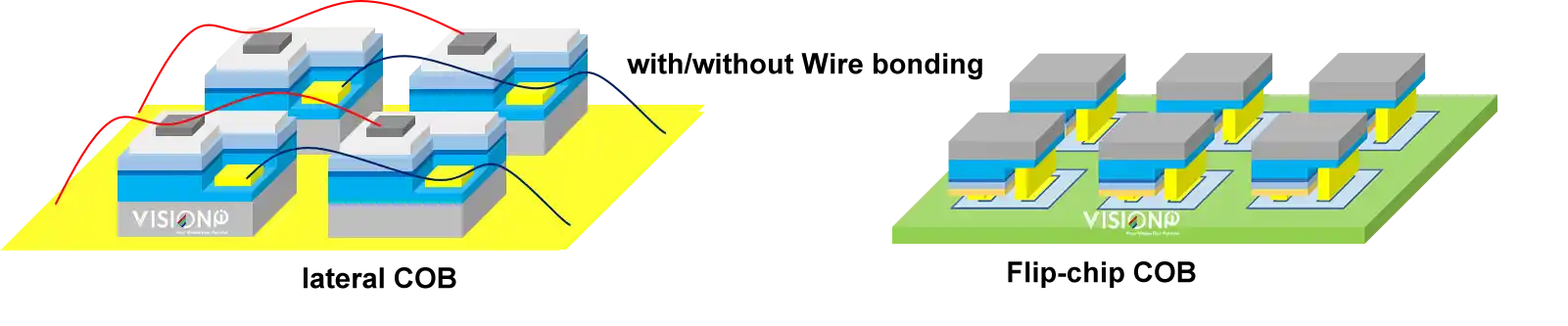

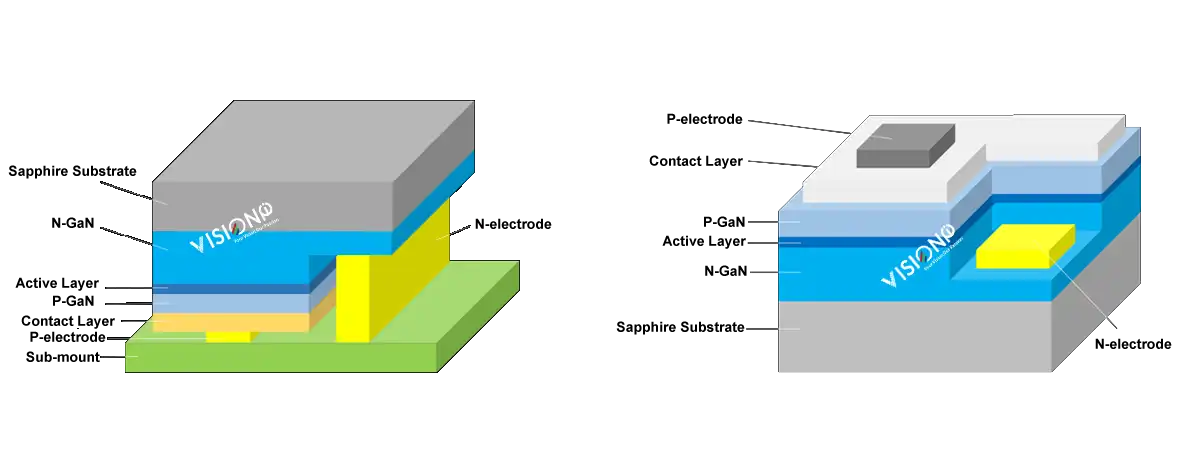

What is COB?

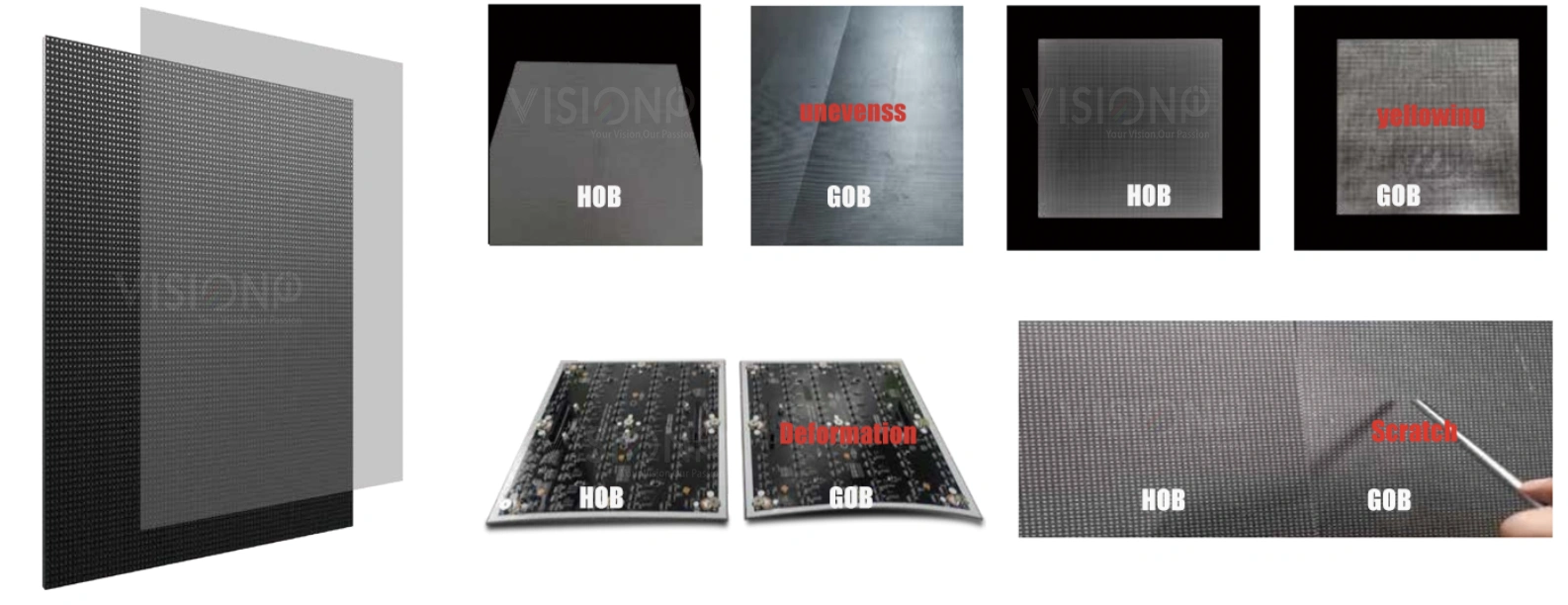

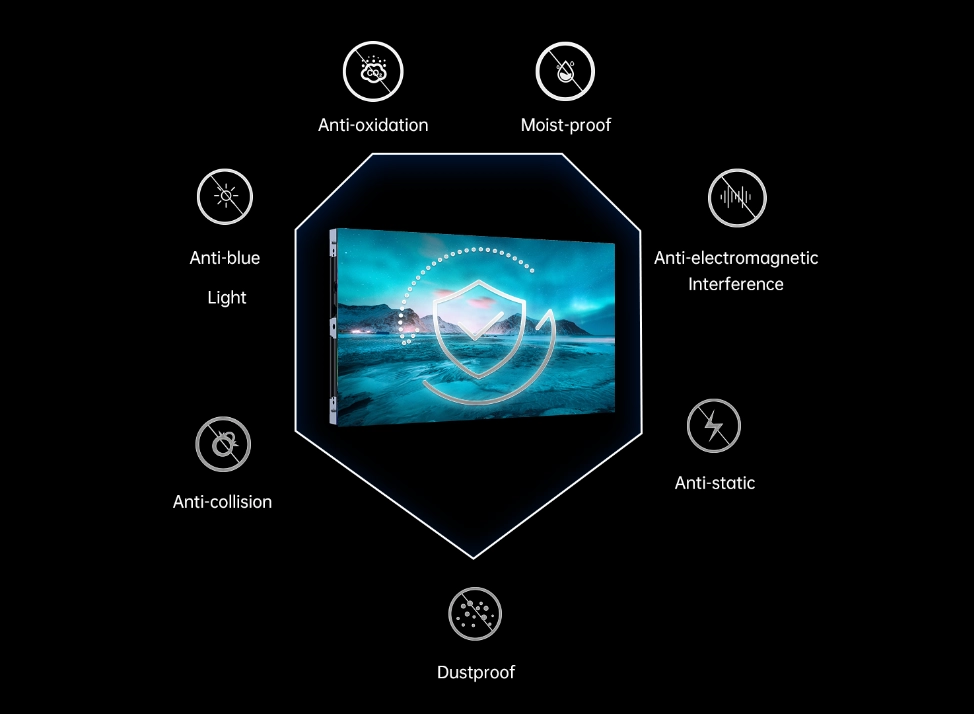

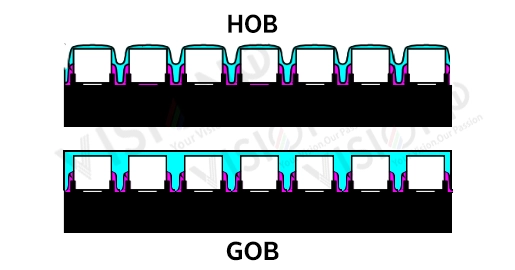

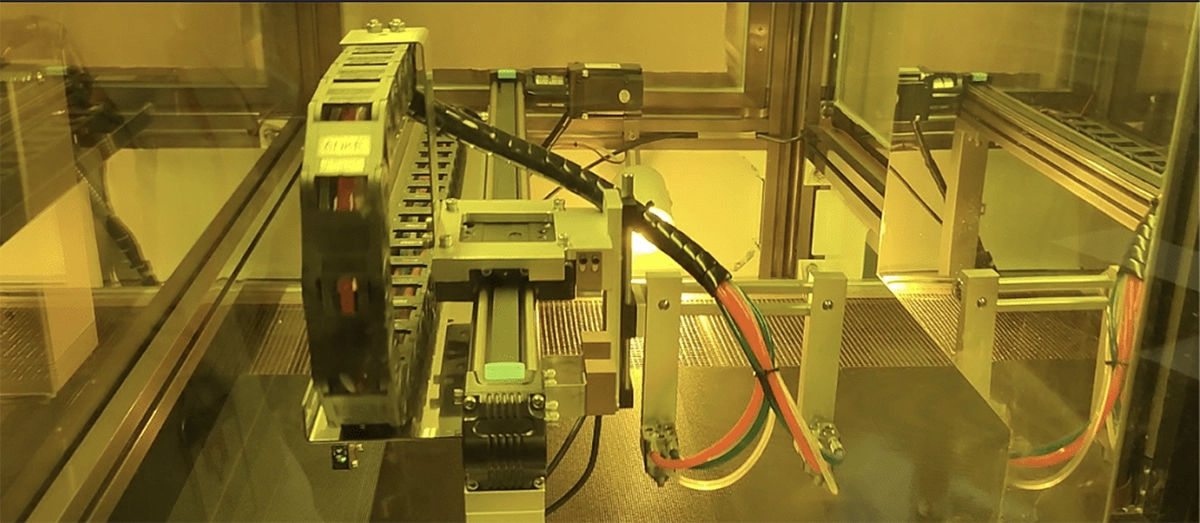

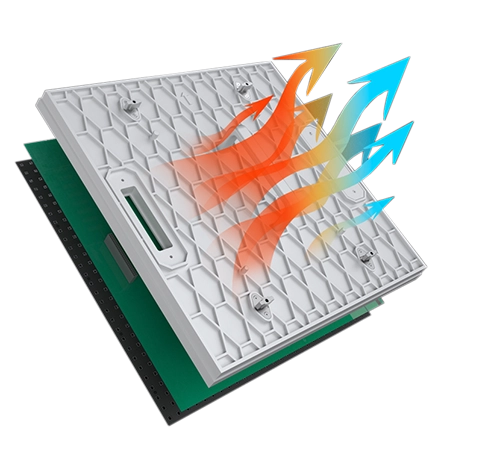

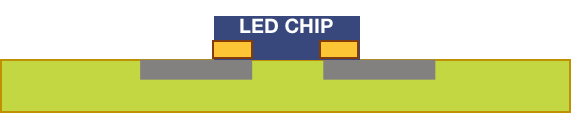

COB (Chip on Board) is a kind of LED display packaging technology. LED light-emitting chips are directly bonded to the module board with high precision and connected to driver components on the module board through special media for overall protection of the light-emitting surface. COB packaging eliminates the two key procedures of turning LED chips into lamp beads and reflow soldering as compared to standard SMD packaging.