LED Display quality control

Understand the LED Display Production Process

Step 1: Technical study

An exclusive professional department with more than a decade of experience in advertising LED screen manufacturing will thoroughly study your needs and the technical concepts required for a new order.

Step 2: Structural design

We will design the frames of a big LED screen to adapt to the features and sizes requested by you perfectly.

Step 3: Assembling of structural components

We will assemble the manufactured structure in such a way that there is no visual separation in the whole unit. All the inside pieces will be placed according to a pattern and perfectly aligned by laser.

Step 4: Electronic components

We will program the assembling of electronic and LED equipment to assure that only the parts corresponding to your order are used. This is one of the most complex and delicate tasks of the entire process. It is the most important phase of creating the LED advertising screen.

Step 5: Assembly of electronic components

We will assemble the circuits we manufacture to create complete panels, which are fully functional and capable of reproducing a full-color image.

Step 6: Tuning and adjustment

We will adjust the LED panels to light and chromatic levels to ensure that sharpness and color are the same in the entire LED advertising screen. To do this, we will use photoelectric sensors measuring chromatic patterns adjusting and memorizing each LED component.

Step 7: General assembly

We will assemble the structural frames and parts to form complete units capable of reproducing videos.

Step 8: Assembly test

We will activate the screen as a whole and carry out exhaustive testing. Once all the tests prove smooth functioning, we will proceed to the image management and control phase.

Step 9: Image test

We will reproduce several test videos during the image control phase. We will analyze the chromaticism and its quality level. Finally, we will tune everything to adjust the whole unit.

Step 10: High protection packaging

We will carefully pack the LED screen into a high-resistance package to ensure product protection during transportation.

LED Display Quality inspection Details

Quality control of LED display is a process of ensuring that the LED display screen meets the desired standards of performance, reliability, and color accuracy. There are several aspects of quality control of LED display, such as:

- Defective pixels: Defective pixels are pixels that do not function properly or do not emit light at all. They can affect the overall appearance and quality of the LED display.

- Uniformity: Uniformity refers to the consistency of brightness and color across the LED display. A good LED display should have uniform brightness and color without any noticeable variations or spots.

- Color accuracy: Color accuracy refers to the ability of the LED display to reproduce the colors of the original content faithfully and realistically. A good LED display should have high color accuracy without any color distortion or deviation. To test for color accuracy, you can use some online tools such as [DisplayCAL], which is a graphical user interface for the display calibration and profiling tools of Argyll CMS, an open source color management system. You can also use a colorimeter or a spectrophotometer to measure the color gamut and color temperature of your LED display.

- Sharpness: Sharpness refers to the clarity and detail of the images displayed on the LED display. A good LED display should have high sharpness without any blurriness or pixelation. To test for sharpness, you can use some online tools such as [Lagom LCD test], which is a series of test images that help you to adjust the settings of your monitor. You can also use some test patterns or images that have fine details and edges to check the sharpness of your LED display.

- Viewing angle: Viewing angle refers to the angle at which the LED display can be viewed without losing image quality or color fidelity. A good LED display should have a wide viewing angle without any color shift or contrast loss. To test for viewing angle, you can use some online tools such as [Viewing Angle Test], which shows you how the colors and contrast change when you view your monitor from different angles. You can also use some reference images or videos that have various colors and contrast levels to check the viewing angle of your LED display.

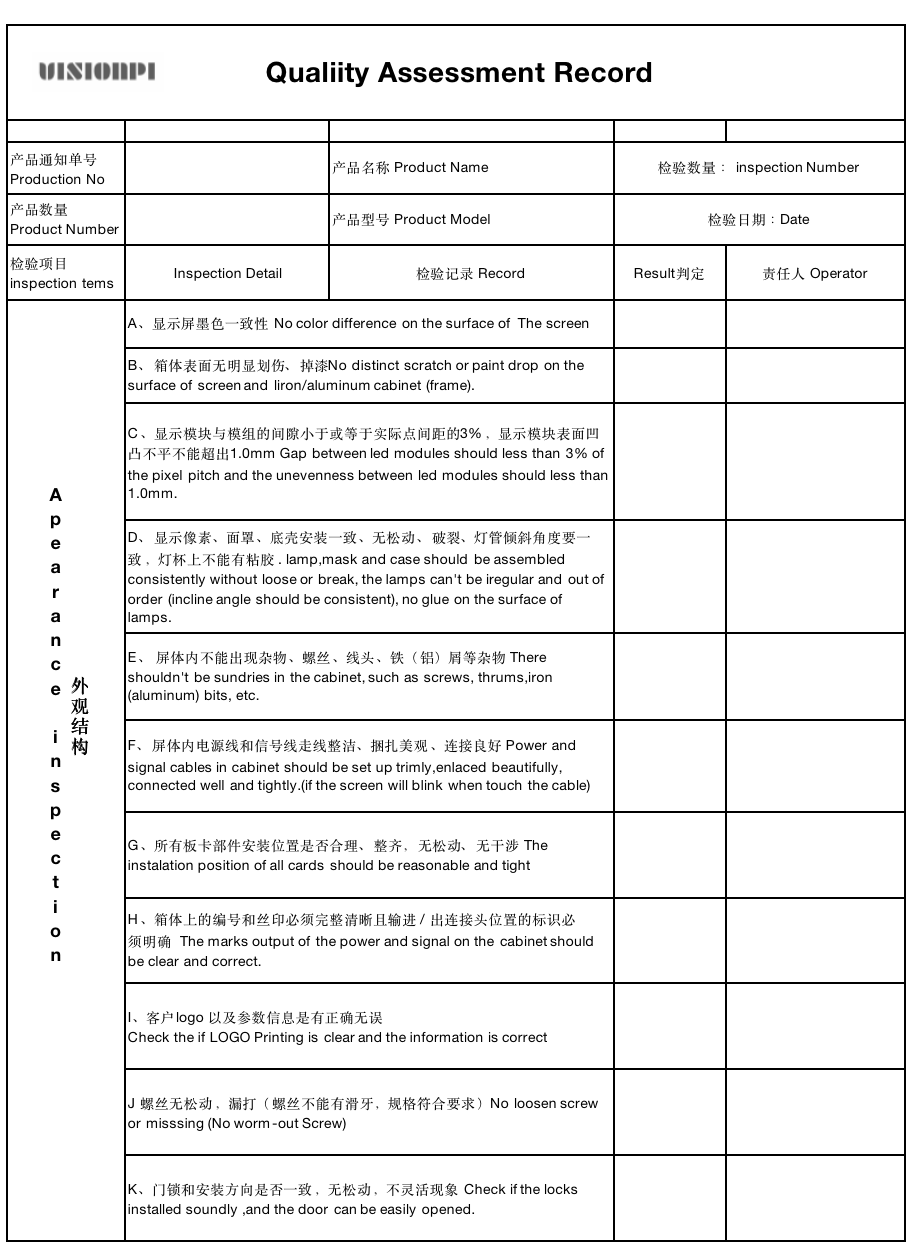

Example of inspection checklists

A good checklist is central to managing quality

Managing quality is a bit like coaching a professional sports team. A big part of the job is about repeating the same thing over and over, to get the basics right.

If you buy a led display from a supplier located thousands of miles away and rooted in a different culture, There should be an order confirmation letter to the customer to check and sign back before arrange the productionyou really need to focus on the basics:

- Document your requirements.

- Make your requirements s specific and testable, so that they are ready to be used as an inspection checklist.

- Ensure your supplier, and especially the people who really count (their purchaser, their manufacturing staff, their quality staff), is aware of your requirements and commits to hitting them.

- Inspect products based on your checklist, and request rework/reproduction if needed..

How to organize a QC inspection checklist

First, you have to think of the best way to guide an inspector through the job. For LED DISPLAY inspection checklist, it generally involves:

- LED Brand (verification, the resources, and the batch number) copper wire or golden.

- Driving IC (Brand and model)

- Power supply and receiving card

- cables (pure copper)

- special functions: calibration or high temperature resistant

- performance( viewing angle, error rate,uniformity of color )

- Appearance check

- Package

- Reliability testing

Then, at each stage, you need to think about what details to check. and what standard?

- Were specific requirements given to the supplier? Go through those requirements that are really important.

- Any safety or regulatory considerations? Definitely cover them.

- Are aesthetics important? Define what to look at and what common issues are to be counted as defects.

- Any function test, endurance tests, or any similar?

Once you know what needs to be checked, the most important questions are:

- How to check this criterion, and what will consider a pass or a fail?

- How many samples should I check for this point? (Some checkpoints take a long time and/or destroy samples, so smaller sampling sizes may make sense.)

- What measuring/testing equipment will be necessary? Will the inspector bring it, or will the factory have to provide it?

LED Display Quality inspection service

VISIONPI QC is a Sino-foreign joint venture quality assurance, project management, and product engineering agency based in China. We are dedicated in A&V products for decades and our key focus is on transparency and control in your supply chain. We offer startups and SMEs the expert assistance you need on the ground in China to improve your relationship with, management of, and quality from your Chinese supply chain,We never hold any of your information for ourselves to ‘lock you in’ We work exclusively for you, and we share and investigate all the information we have in or out of our database for you.

Dedicated & professional 👍👍

Thanks Robert

Show me your email address. We would like to send our PO.

Highly appreciated. My email:william@vision-pi.com

We are the LED TV manufacturing company in Iran that has commercial and technical cooperation with several suppliers for SKD parts of TV in China.

We need comprehensive quality inspection service of LED TV panel in China.

We would like to know your service and quality inspection process exactly and inquire about your service tariff and rate.

sure. please leave your email