Unlocking Flexibility and Savings with Modular LED Displays

In the evolving world of digital displays, modular LED displays are gaining traction for their unmatched flexibility and efficiency. Unlike traditional LED screens that come pre-assembled in bulky cabinets, modular LED displays consist of independent modules that can be directly installed onto a frame. This innovative approach not only allows for customized screen sizes but also offers significant savings in space and cost. In this blog post, we’ll delve into the advantages of modular LED displays and provide a comprehensive guide on how to install them effectively.

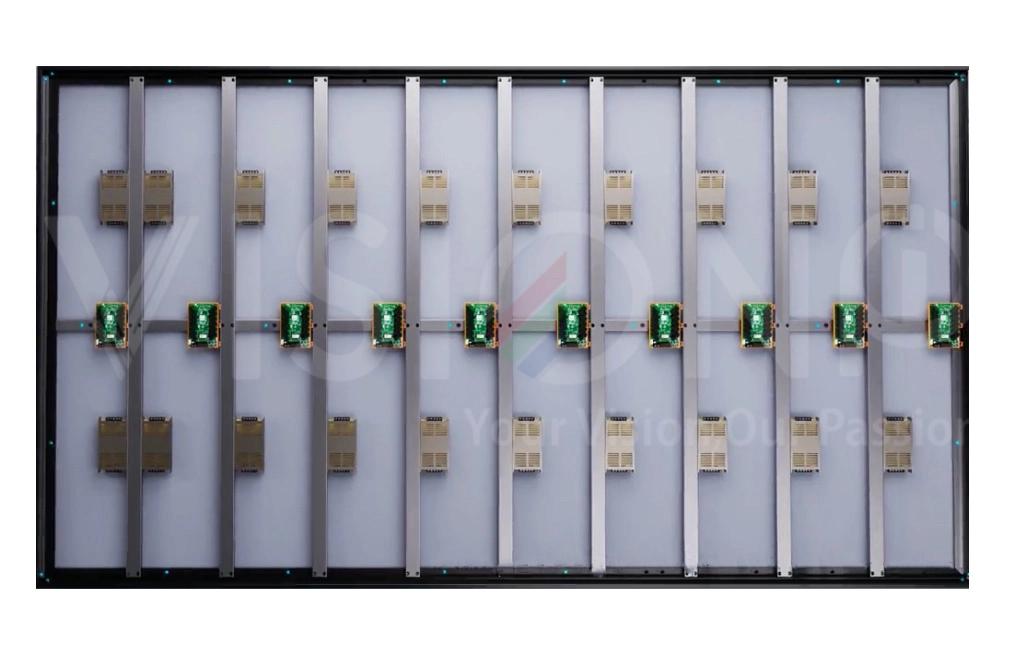

Modular LED Display Installation Guide

- Preparation:

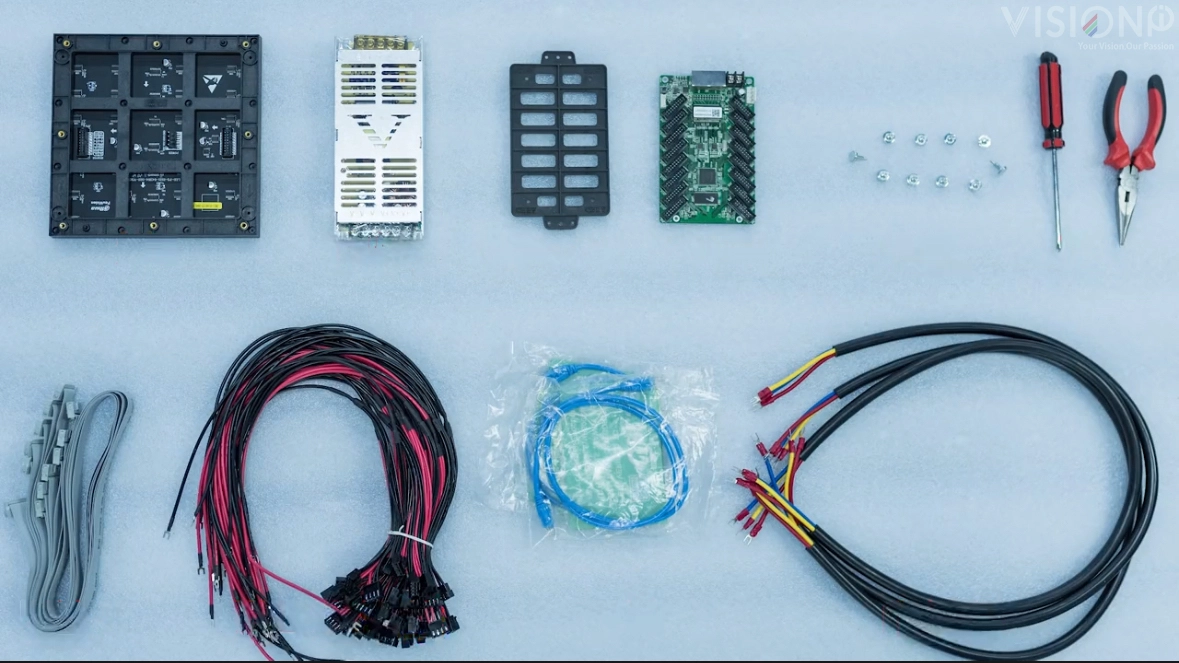

Assess the Installation Area: Measure and evaluate the space where the display will be installed. Ensure the wall or structure can support the weight of the modules. - Gather Necessary Tools and Components:Besides the LED modules, ensure you have all mounting brackets, screws, and tools at hand.

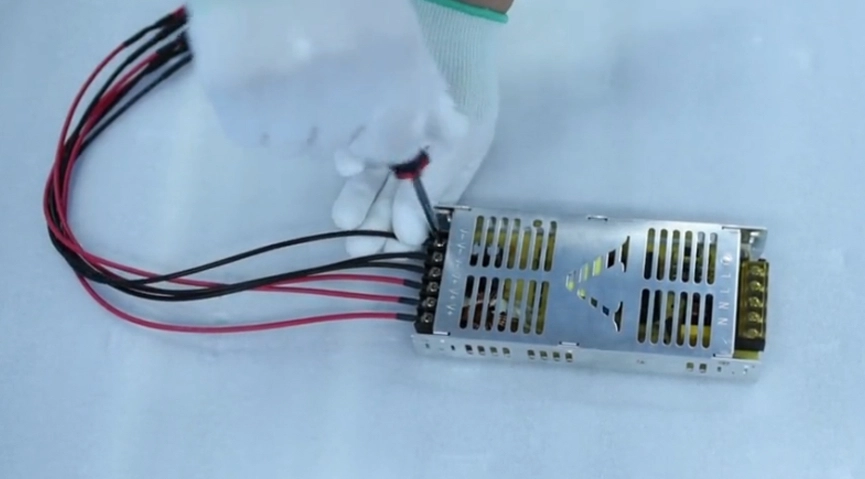

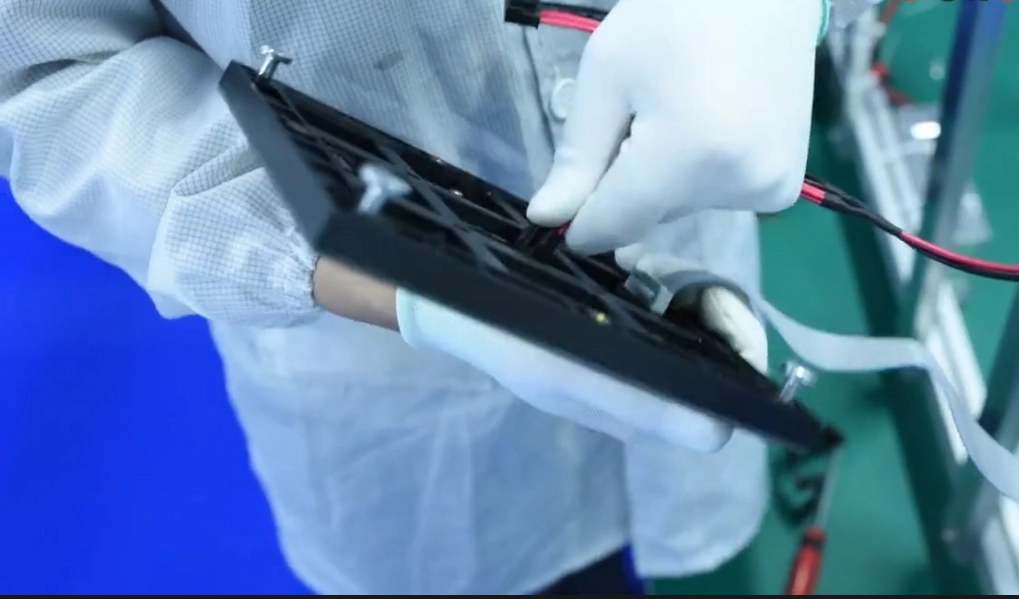

4. 5V Power Cable Wiring: Essential for powering the LED modules, the 5V power cables should be connected from the power supply to the LED modules ensuring secure and stable connections. Use appropriately rated cables to handle the current requirements and minimize voltage drop across long distances.

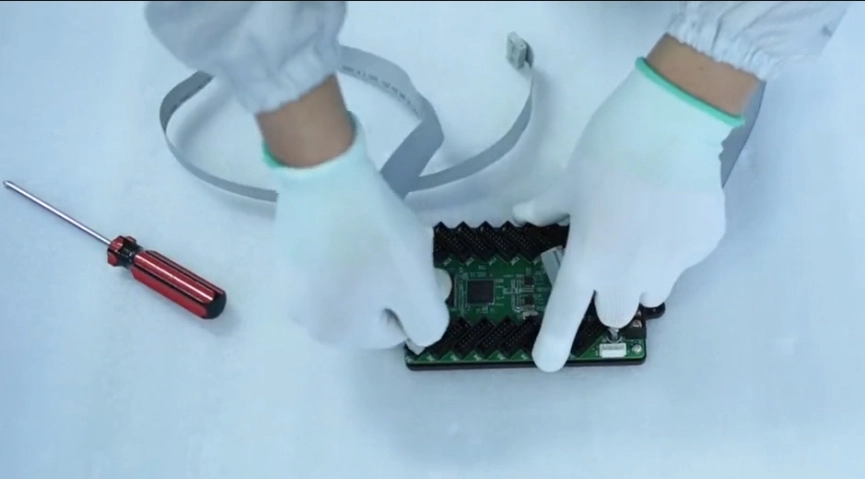

5.Receiving Card Wiring: This involves connecting the receiving card to the LED modules using flat cables. The flat cables transmit data signals and need to be carefully routed to avoid interference and ensure stable signal transmission.

Advantages of Modular LED Displays

- Customization: Modular LED displays can be tailored to fit led screen size more flexiblely than the cabinet type.

- Space Efficiency: By eliminating the need for bulky cabinets, modular LED displays can be integrated into environments where space is at a premium. This makes them ideal for locations like retail stores, art galleries, and places where aesthetic integration is crucial.

- Cost-Effectiveness: With modular LED displays, you’re investing only in the technology you need without additional structures. This not only reduces the initial investment but also decreases shipping and labor costs due to the lighter and more compact nature of the modules.

- Ease of Maintenance and Upgrades: Since each module can be accessed and replaced individually, maintenance and upgrades become simpler and less disruptive. This modular nature ensures that the display can evolve over time with the latest technology without needing a complete overhaul.

- Improved Heat Dissipation: Without the confinement of a cabinet, modular LED displays typically have better heat dissipation. This can lead to longer lifespan of the LEDs and reduced risk of overheating, ensuring consistent performance even in challenging conditions.

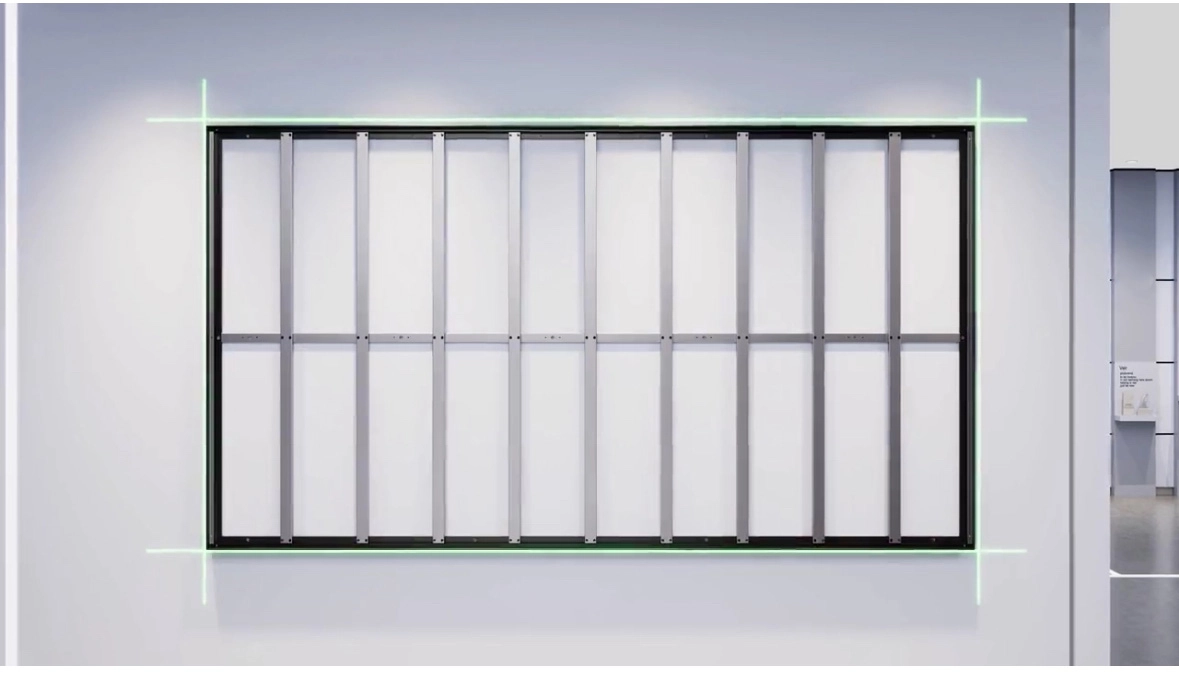

3.Frame Setup: Construct the Supporting Frame: Depending on the design, this could be a simple rectangular frame or a more complex custom shape. The frame should provide stable and even support for the modules.

4.Secure the Frame: Fix the frame securely to the wall or structure, making sure it is level and sturdy.

Installing LED Modules

- Mount the Modules: Attach each LED module to the frame, starting from one corner and working your way across to ensure alignment. Use the mounting brackets and screws provided.

- Connect the Modules: Wire the modules together according to the manufacturer’s instructions. This usually involves connecting power and data cables between modules.

- Configuration and Testing:System Configuration: Once all modules are installed and connected, configure the display using the control system provided by the manufacturer.

- Testing: Test the display for all functionalities. Check for color uniformity, brightness, and connectivity issues.

- Final Adjustments:Calibration: Calibrate the display for optimal color and brightness to match the installation environment.

- Cleaning and Finishing Touches: Clean the surface of the modules and remove any installation debris. Add any protective coverings or aesthetic finishes as required.

Interested in exploring the potential of modular LED displays for your business or next event? Contact us today to find out how our cutting-edge solutions can be tailored to fit your unique requirements.

Upgraded Cost Effective Plastic Cabinet LED Display

Advantages of Plastic-Cabinet-Type LED Displays

- Precision Alignment:Plastic Cabinet-type displays, especially those with Die-cast cabinets, are produced with high precision due to their machine-made nature. Features like interlocks and module positioning holes ensure perfect alignment. This contrasts sharply with cabinet-less designs, which rely on less precise handmade structures that can affect the final screen alignment.

- Enhanced Flatness: The flatness of an LED screen is crucial for providing a seamless visual experience. This level of flatness is difficult to achieve with mild steel (MS) cabinets and nearly impossible with cabinet-less screens, which often suffer from inherent structural unevenness.

- Reduced Fire Hazard : Safety is paramount in any installation, and cabinet-type LED displays offer significant advantages here. Each cabinet in these designs is equipped with an internal electrical terminal block, which acts as a first line of defense against electrical shorts, cutting power to prevent potential fire hazards. In contrast, cabinet-less designs expose power supplies and cables to increased risk, as they are often mounted directly on flammable materials like plywood.

- Protection Against Environmental Hazards: The structured framing of cabinet-type displays, , effectively shields the internal components from dust, insects, and rodents. This enclosure prevents damage that could lead to electrical shorts and hardware failure, issues that are more prevalent in cabinet-less designs due to their open construction.

- Compliance and Safety Certifications: Cabinet-type displays are often backed by quality and safety certifications that are not typically available for cabinet-less modules. These certifications assure buyers of the product’s compliance with international standards, reducing the risk of purchasing substandard or unsafe products.