LED Display Flight Case

ATA Cases, also known as Road Cases, Flight Cases, and Anvil™ Cases are used for the storing and transportation of high-value items, or items that need to travel hundreds of times throughout their life. Some of our customers that use cases are sports teams, rock bands, tech, and trade show companies, as well as musical and scientific instrument manufacturers and aerospace and space exploration companies. A flight case can be small enough for a handheld drone or large enough for a rocket nozzle.

Video Processor Flight Case

Video processor Flight case give a overall protection to the video processor. A simple suicase design,carried like a bag. customized for Novastar LED Processor; Linsn Video processor.

The key benefits of using flight cases include:

- Protection: Road cases help protect items from physical damage, shock, vibration and moisture.

- Durability: Road cases are designed to withstand a lot of wear and tear and often have a long lifespan.

- Versatility: Road cases can be customized to fit a variety of items and are available in a range of sizes, shapes and materials.

- Convenience: Road cases are easy to transport and often feature wheels, handles and other built-in features that make them easier to move.

- Security: Many road cases include locks, straps, buckles and other security features to help protect items from theft or loss.

How to Choose Flight Case for Display Screen

The most popular materials used in road cases include aluminum, plywood and plastic.

The most common are the durable and handsomely covered ABS laminated black wooden road cases with aluminum tongue-in-groove edges, recessed steel handles, and heavy-duty steel ball corners. Depending on what the road case is intended to house, the interior can be felt, carpet, bare wood, or custom cut foam inserts.

- Aluminum is strong, lightweight, and corrosion-resistant making it a great choice for protecting delicate equipment.but the cost is usually more.

Plywoode Flight case

Plywood offers strength and durability,Wood is a lightweight and affordable material that offers strength, durability, and protection.For long-term cases that must withstand physical stresses such as drops and sudden jolts, solid materials such as plywood or aluminum are an ideal choice due to their durability.

Hexagrip board

Hexagrip is a high-quality plywood panel with a black phenolic film on both sides. One side has a hexagonal texture that makes it resistant to slipping and scuffing. The other side is smooth and easy to clean. The plywood base is made of thin layers of birch veneers that are glued together. This makes the panel stiff and flat, but not brittle. The thickness of a typical 9 layer (3/8”) panel is very precise, less than 0.03 inches. The phenolic film is not only attractive, but also durable. It can withstand impacts, scratches, marring, grease and fingerprints. It is also bonded to the plywood base with a chemical process, so it will not peel off or bubble under heat or sun exposure.

High Pressure Laminated Board

HPL panels consist of a single-sided plastic sheet glued/laminated to varied quality and ply ACX softwood plywood or solid-core hardwood (luann or meranti) substrate. Unlike the phenolic coating of Hexagrip, the bond of the plastic coating on ABS laminate varies in quality based on the manufacturing process of the composite panel. ABS panels are only as good as the quality of the plywood, glue bond, and your ability to keep them out of the sun. Frequently, case manufacturers will stock several different qualities of ABS laminate in varying thicknesses, based on their price point, and availability.

Plastic Flight Case

Plastic provides flexibility with features such as latches, handles and locks, if a lightweight and portable solution is desired, plastic may be preferred over more heavy metals or composite boards. Plastic also has better waterproof ability but working under high temperature will be a big chalenge

Flight Case Key components

Flight Case Corners

Flight case corners are essential to protect cases from damage, especially as impact points on most cases are the corners. Corners are most commonly made from heavy-duty steel but also come in plastic. Ball corners provide greater impact protection, but case corners come in a large range of sizes and shapes.

Road case handles

flight Case Hangles are important for moving your case around easily and safely. There are different kinds of handles for different purposes. Some handles are recessed, which means they fit into a hole in the case and don’t stick out. This protects them from getting damaged by bumps or scratches. Other handles are surface or strap handles, which are attached to the outside of the case. These are usually used for smaller cases like briefcases or guitar cases. Some handles are pull out handles, which can extend and retract like a suitcase handle. These are good for heavy cases that need to be rolled on wheels. Some handles are corner handles, which are placed on the corner or edge of the case. These give you a better grip on the case.

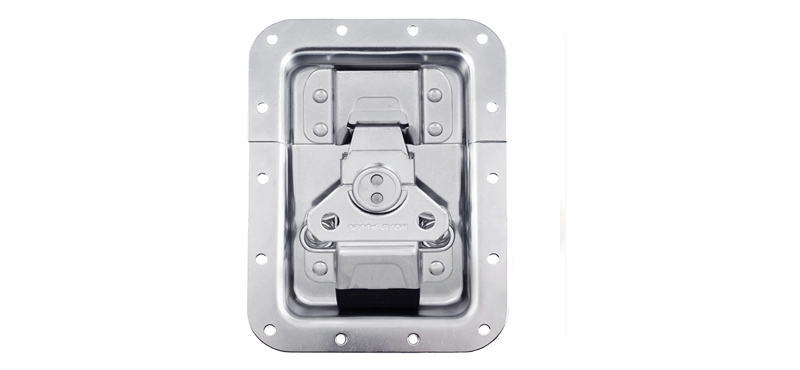

Flight Case Laches

Latches are the parts that let you open and close your road case.

There are many kinds of latches for different needs and preferences. Some latches have locks or padlocks to keep your case secure.Some latches are recessed, which means they are inside a hole in the case and have a dish around them. This helps them avoid getting hit or scratched when you move the case. Other kinds of latches are surface latches, slam latches, overlatches and small latches for briefcases or drawers.

Flight case Wheel/Castors

Castors are the parts that let you move your road case easily, especially if it is heavy. Castors or wheels can turn in any direction, so you can steer your case where you want.

Road case castors are made of strong materials like steel or zinc with rubber wheels. They can last for a long time and handle rough surfaces.

Castors come in different sizes and some have brakes to stop your case from rolling away. Some castors also have a special feature that makes them align with each other when you stack your cases. This makes your cases more stable and saves space.

Usually, castors are attached to the bottom of the case, but you can also put them on the corner of the case with special castors made for that.

Flight case Foam

Road Case Foam and carpet are the materials that keep your case contents safe and secure. They act like a cushion that wraps around and pads the item or items inside the case.

There are different types of foam and carpet for road cases. Foam can be cut with a CNC machine to make the perfect shape for the item you want to transport. This way, the item won’t move or shake when you move the case.

Carpet gives a soft and smooth lining inside the case. It also makes the case look more professional and neat. You can choose from many kinds of carpet materials and colours to suit your needs.