Since the advent of SMD in 2001, the market share of DIP (direct insertion pattern) packaging has been shrinking annually. However, DIP is still used to ensure product reliability in harsh environments like high-altitude or ultra-low temperature conditions. SMD has played a dominant role in LED packaging for more than a decade. It was not until 2016 that COB began to attract more market attention.

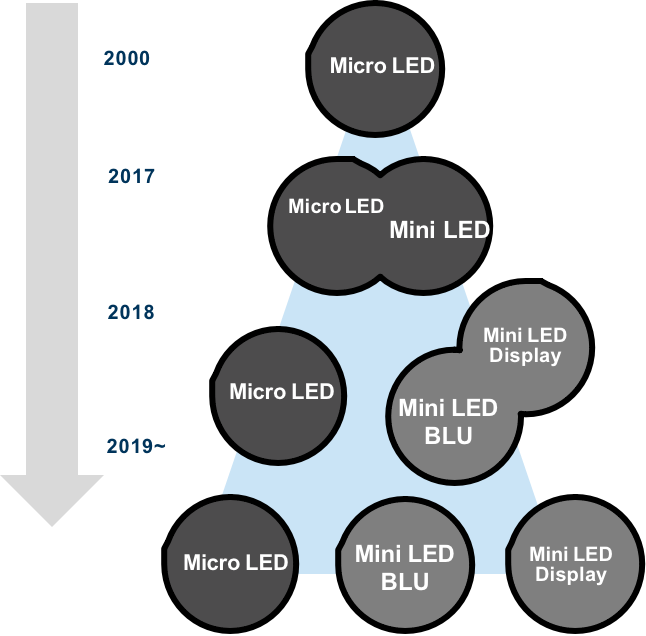

In 2017, SONY launched a Micro-LED display based on flip-chip COB, which inspired the industry to further explore the COB development path. At the end of 2017, the concept of Mini-LED was raised. That greatly accelerated the evolution of pixel pitches towards a finer level. Limited by technology and equipment, conventional single diode SMD packaging reaches it’s smallest size at 0.5*0.5mm. Any smaller packaging size from this point is no longer processable by the current SMT process. This physical limit encouraged the entire industry to explore other technologies such as COB (especially flip-chip COB) to continue its technological evolution.

In 2018, NationStar launched its 4-in-1 IMD09 and put forward the concept of IMD, which combined the advantages of both SMD and COB. This officially began the three-way race between SMD, IMD, and COB in the fine-pitch LED display industry.