CHOOSING THE RIGHT LED DISPLAY!

CHOOSING THE RIGHT LED DISPLAY!

Video walls can create stunning centerpieces for a variety of spaces. LED video displays can transform any environment, but you may become overwhelmed when you look at all the options on the market. There are many elements to consider when selecting video screens, including indoor vs outdoor, pixel pitch, front vs rear serviceability, and shape. If you aren’t sure where to start, VISIONPI has products to fit every need.

So Many Video Wall Options—Where to Start

To get started, it’s essential to understand the basics. Here are some fast facts you should know:

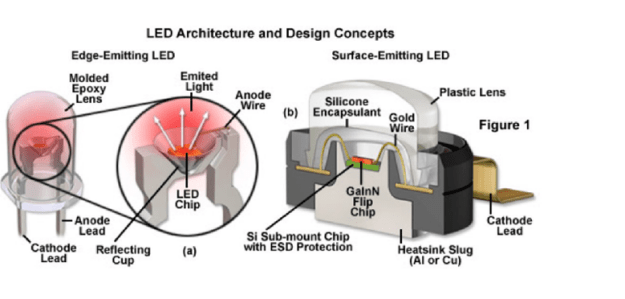

- An LED (light emitting diode) is a semiconductor device that emits visible light when an electric current passes through it.

- LEDs require much less power than other types of screens powered by incandescent lamps, offering greater efficiency and a longer lifespan.

- Indoor LED screens have wide-viewing angles, no color shifts, and have a smooth appearance from a short distance.

- Outdoor LEDs are weather-proof, very bright, and are ideal for longer viewing distances.

- Brightness is a key element in designing your video wall and is measured by nits. Indoor LEDs typically have 1000-1500 nits while outdoor LEDs have 2000-3000 nits. A nit is almost 3.5 times brighter than a LUX, the measurement of brightness used by projector screens.

- Pixel pitch is another important part of LED selection. Pixel pitch is the physical distance from the center of one pixel to the next, measured in millimeters. The higher the number, the fewer pixels, and lower resolution. Depending on viewing distance, you’ll need to determine the right pixel pitch for optimal resolution. A general rule is 3.28 feet per 1mm of resolution.

- Cost and budget are always a consideration. LEDs have a higher initial investment than projectors but last much longer.

Finding the Right Video Wall Equipment for Your Project

If you aren’t an AV expert, selecting the right LED video wall may seem difficult. It’s important to educate yourself on the basics of LED screens, as provided above. This gives you a foundation to begin your search. As you work with those that have specific expertise, like VISIONPI, you’ll know the right questions to ask about pixel pitch, brightness, and longevity.

To narrow down your selection, ask these questions:

- How will you use the display? Does it need to be the central element in a setting? Or is it a backdrop?

- Are you using the displays inside or outside?

- Will it be viewed from long or short distances?

- How will it be mounted? Does the area require a certain shape or curvature of the screen?

Depending on your answers, you can narrow down exactly what you need to bring your ideas to life.

Products for Every Video Wall

VISIONPI has a large variety of award-winning LED displays. We can create nearly any size or shape screen required. From indoor to outdoor to curved configurations, there’s a perfect product for every installation.

You may have specific goals for your video walls—attracting attention, upselling, increasing curb appeal—and our team of experienced professionals will help you reach that goal. As a full-service LED provider, we collaborate with customers creatively to ensure the best experience.

Stay Up to Date With The Latest News & Updates

Access Premium Content

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque

Join Our Newsletter

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque