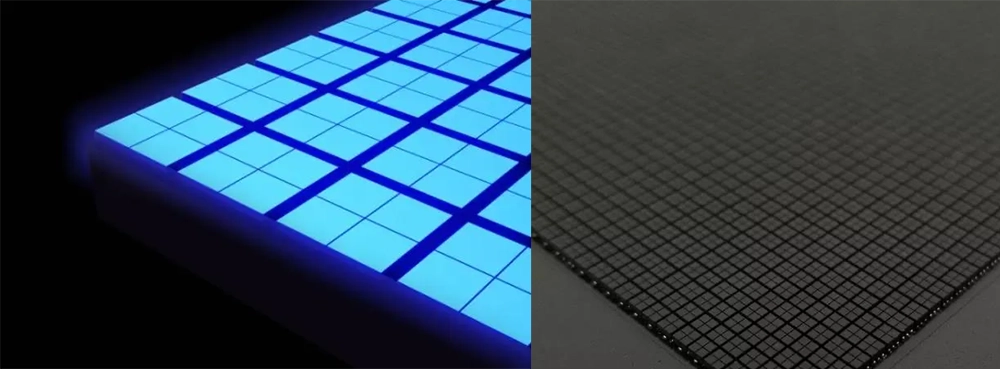

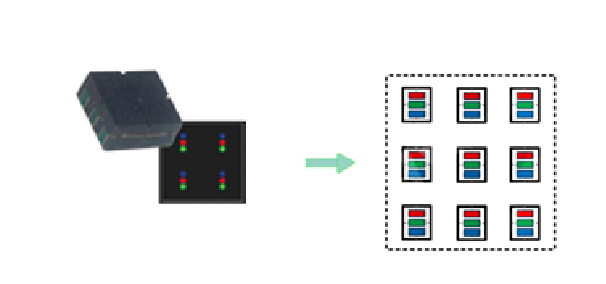

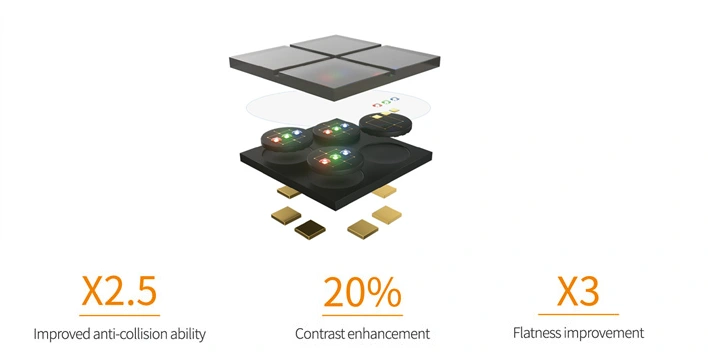

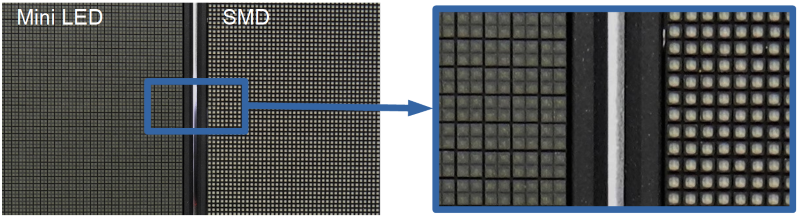

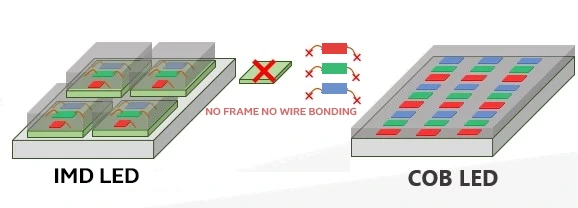

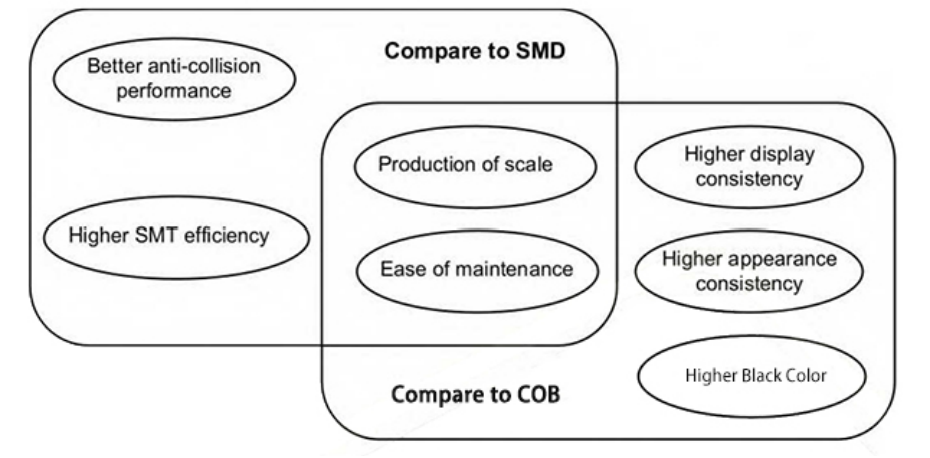

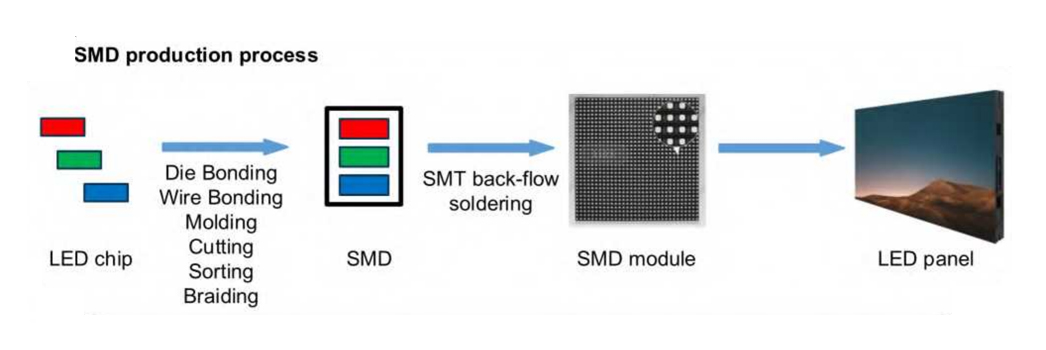

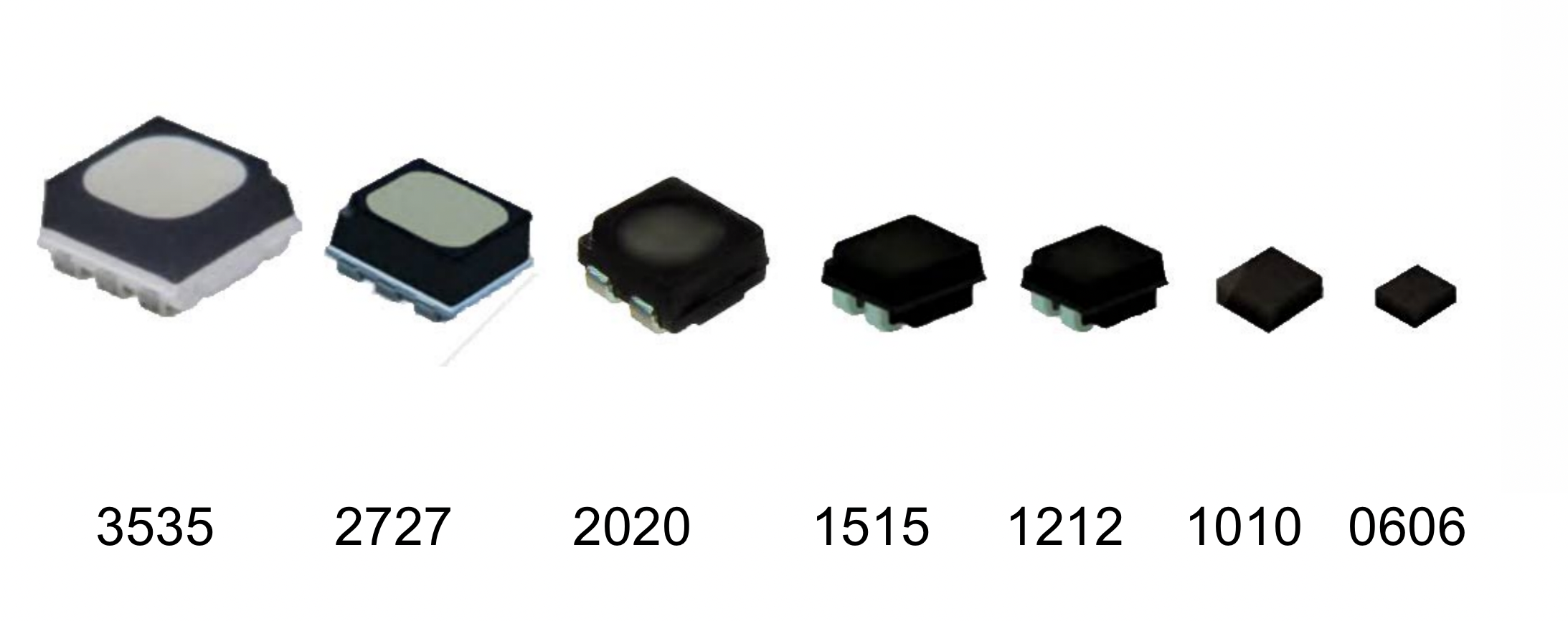

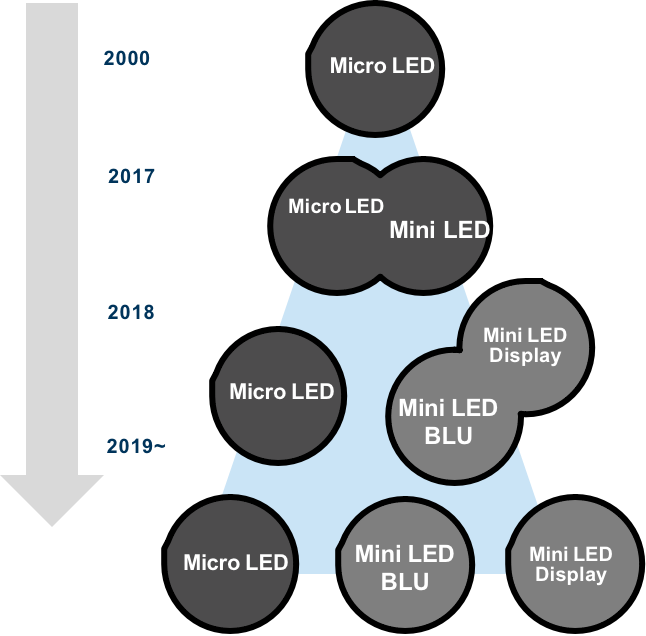

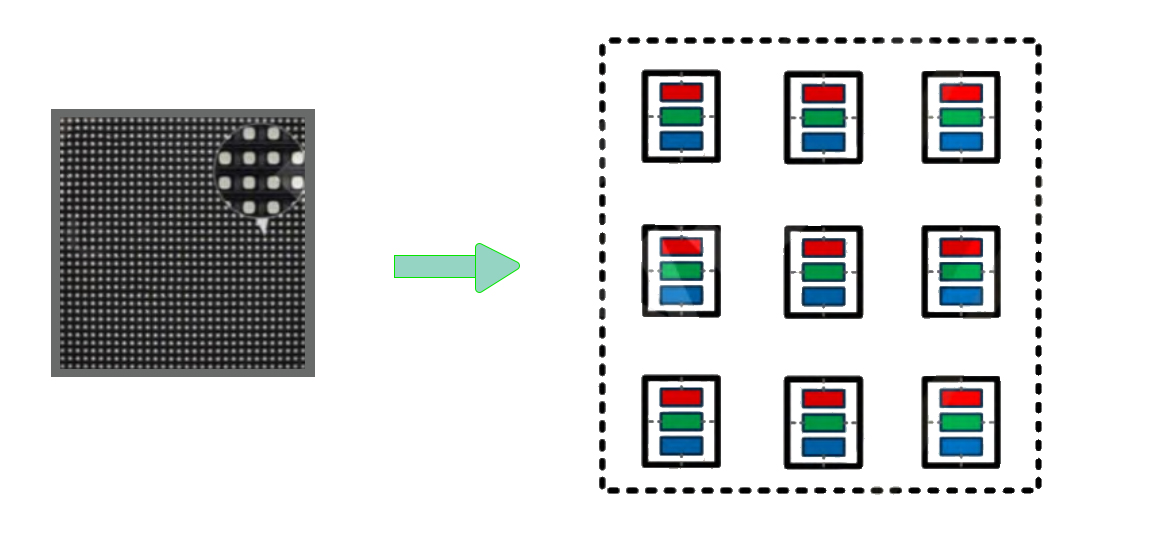

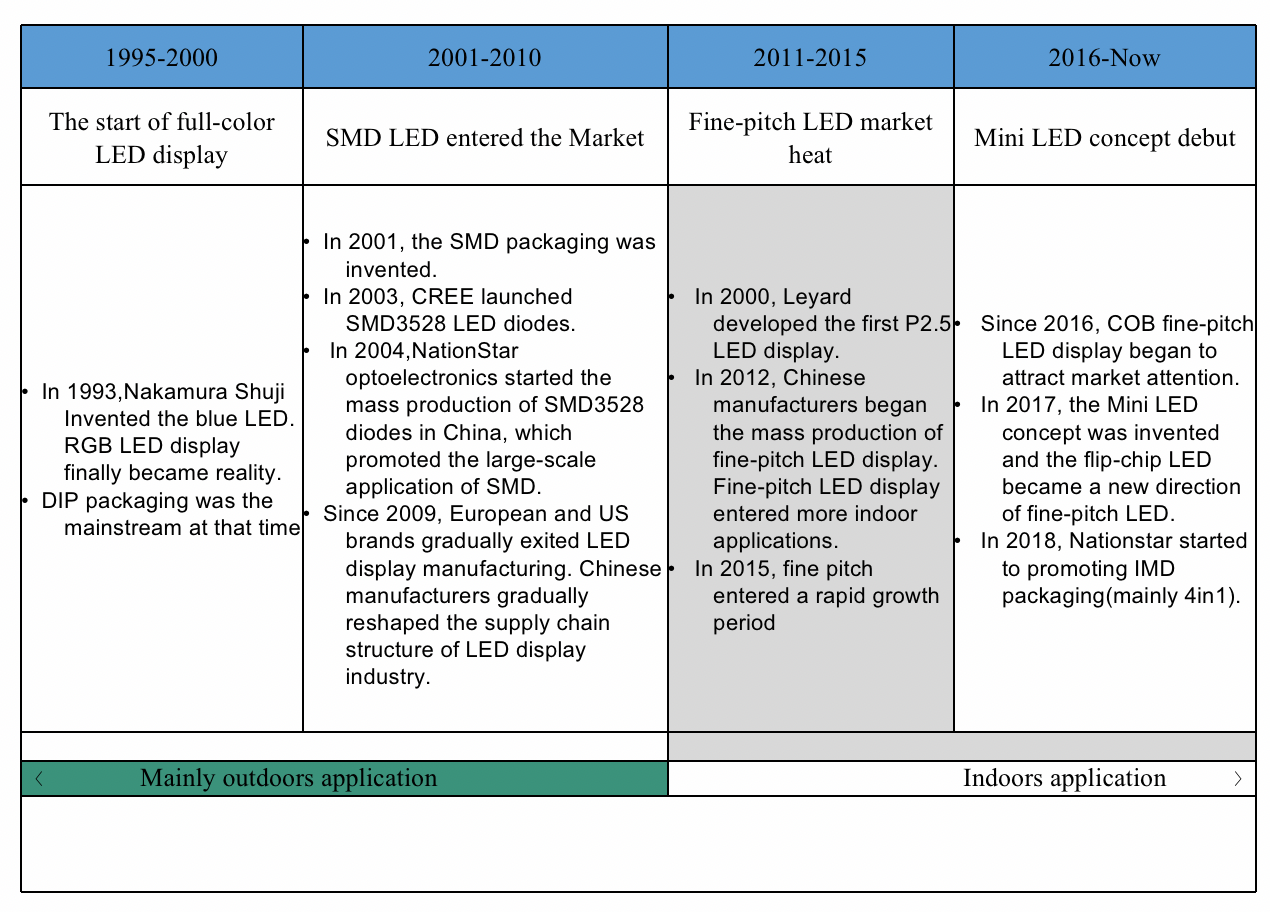

IMD LED display (Also called Mini LED Display) is one of the latest fine pitch led package technology. In the field of LED display, with the development of upstream packaging technology, there gradually form two different LED display panel preparation technologies, SMD and COB. We can use these two technologies to produce small-spacing mini LED display screens. And we will share some information about these two technologies with you.

Top 10 led sign board manufacturers

Since purchasers need to get the best LED, they are consistently keeping watch generally advantageous and confided in maker also. LED video divider has gone to be a persuasive wellspring of on location promoting and in this manner; LED manufacturers are required to send the best items on the lookout. In any case, the inquiry is how to ensure that the maker is solid and creating great China LED displays? When scouting for the best-LED LED DISPLAY MANUFACTURER, you’ve got to be sure about a couple of things including the size, Authentication, after sales service ,technology background and their product lines.You’ll need to think about the budget and the payment terms too, depending on your needs.

Trustworthy : The most importantly thing is to sort out if the LED display screen producer is dependable. On the off chance that somebody is delivering P10 LEDs, they are the most trusted and purchasers can aimlessly take any item from them. Organization notoriety is another main consideration alongside client surveys and tributes. This load of variables is the way to discovering legitimacy of a maker.

Financial plan: The following significant thing is to decide the financial plan. Since each purchaser has a few limits, it’s important to assess the degree to which they can proceed to purchase a LED display. According to a producer’s perspective, the cost for LED display screens will differ as per their strategies, nature of material and different variables.

Involvement :The prospect of purchasing commercial digital display solutions is daunting, in no small part due to the complexity of everchanging industry jargon. The fluidity of many of the industry’s most common –yet most confusing- specifications can make the precise definitions of these terms quite difficult to pin down. Due to the complexity of the led screen, ever-updating technologies, increasing intense competition, flooded suppliers’ information, it is getting more difficult to find or choose the right products and suppliers. With the knowledge of their experience, purchasers are having confidence about the nature of LEDs they will get.

1.Leyard Group

Famous for being a global name in LED industry, Leyard Group is one of those manufacturers who have been using audio-visual technology since years. Its products are the result of technology research, development, creativity and product innovation. Its business layout comprises of four core elements: landscape lighting, virtual reality, intelligent display and cultural tourism. Leyard Group was awarded the National Technology Innovation Demonstration Enterprise, National Culture and Science, Beijing Top 10 Information Industry, Technology Integration Demonstration Enterprise and China’s Top 100 Electronic Information Enterprises awards.

2.Unilumin

Since its foundation in 2004, Shenzhen Unilumin Group Co. has arisen as one of the main LED manufacturers. The organization is likewise giving answers for the assembling, advancement, deals and post-deals administrations. Their vision is to cooperate for a more promising time to come and in this way; clients can hope to have superior, great LED display items alongside the dependable review arrangements. The organization has been gladly fabricating full-shading, top quality LED display screens and lighting. Their help and deals network has reached more than 100 nations where there are in excess of 700 channels and 16 workplaces and auxiliaries to serve the clients.

3. ROE Visual

ROE Visual stays consistent with its words and attempts its level best to change clients’ assumptions into the real world. This LED display maker delivers best, remarkable display screen for business applications. From engineering and lovely transmission establishments to the top stage anyplace on the planet, ROE Visuals has kept up with its greatness, maximal inventiveness, simple of-utilization and solidness.

ROE Visuals has been working as per clients’ assumptions and has figured out how to deliver a scope of LEDs appropriate for HD broadcast, control room, compositional, games, visiting and rental market, places of-love, corporate and different applications.

4. InfiLED

Known as a cutting edge undertaking in China for presenting enormous LED video display, Infield endeavors to investigating new entryways for constant improvement and autonomous development. The organization has been investing heavily to stay at a main situation with its wide scope of item applications. Their made China LED display screens are utilized in corporate gatherings and marking, transportation, order and control, innovative applications, sports, commercials and significantly more. Their items have arrived at in excess of 85 nations of the world with TUV, RoHS, CCC, FCC, ETL and CE affirmations.

With the assistance of dependable parts and progressed creation strategies, InfiLED has been conveying the best nature of items. The organization used to follow guidelines as expressed by Total Quality Management System, OHSAS18001 Occupational Health and Safety Management System, ISO9001 Quality Management System and ISO14001 Environment Management System. InfiLED follows the idea of ‘Five Stars Culture’ and attempts its level best to guarantee one of the best positions in the LED producing industry.

5. Yaham

The organization has brought its hands into the assembling of LED lighting, China LED display and LED traffic signage. Situated in Shenzhen, Guangdong, Yaham Optoelectronics Co. is into planning and delivering great LEDs for clients in everywhere. The organization deals with the soul of compulsiveness and artisanship to guarantee proficiency in hand crafted and solid LED display frameworks. Yaham Optoelectronics is gladly serving more than 112 nations and has figured out how to support its situation as the pioneer of LED innovation. It is the main maker to present hand crafted display frameworks. The organization is as yet on the dubious of reevaluating strategies to update display screens with the goal that clients can have a superior encounter a while later.

6. LedMan

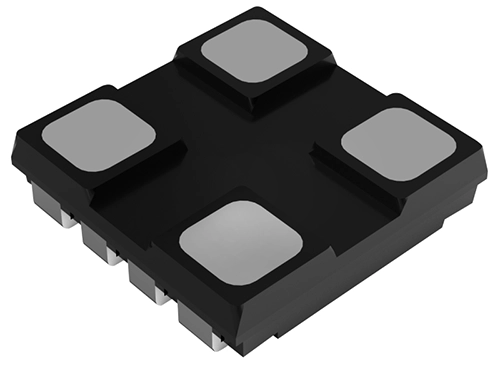

Shenzhen based organization, Ledman Optoelectronics Co. has been in the LED business since 2004. It has been considered to deliver some cutting edge LED items alongside viable visual arrangements. The organization represents considerable authority in working for the 8K UHD industry where they are gladly fabricating a full scope of items. What makes LedMan unique in relation to others is their hands into 8K miniature LED UHD display items that work on cutting edge COB LED innovation. It is a result of their demonstrable skill and proficiency that LedMan is presently an essential accomplice in the avionic business of China.

Today, LedMan is filling in as a main UHD display screen organization, thorough games administrator, worldwide LED industry chain accomplice and cutting edge benchmarking undertaking in China. The organization additionally own and LED item environment comprising of UHD Micro LED display things (having COB trend setting innovation), keen LED lighting, complete games activity, LED arrangement portfolios, 5G astute meeting frameworks, city lighting undertakings and data joining arrangements.

Aside from giving quick inclusion to 5G administrations, it pursues most recent directions of the time. From 5G+8K+AI, the organization is effectively giving the data biological system to five distinct regions, specifically edge registering (EC-IOT), chip arrangement joining, server farm item arrangements, shrewd city and savvy vehicle computerized arrangements..

8. Liantronics

Liantronics is another dependable China LED display producer that offers framework answers for high and medium-end LED display items. Being a state-level endeavor having 97.8 million USD of enlisted capital, Liantronics has practical experience in the turn of events, assembling, deals and post-deals administrations.

9. AOTO

It is an expanded holding organization that comprises of 4 vital units, to be specific financial hardware, sports activity, best LED display and lighting designing. The organization has developed two or three years and put forth a ton of attempts to acquire a spot among the world’s driving LED display manufacturers on the planet. It prides for delivering a wide scope of outside and indoor direct view display items.

10. Desay

Another LED display producer who is assuming a huge part in the business is Desay. Its own control framework, coupled with advancements like optics, electron and especially, pixel-by-pixel alignment method empower the organization to make particular degrees and striking photos of the administrations. It has effectively installed more than 5000 LED across the world, regardless of how much endeavors it needed to make.

Conclusion

Thinking about this rundown of top China LED manufacturers, it would be very simple for individuals to concoct a suitable decision. There are no rigid guidelines about the determination model. Individuals can pick whoever suits their prerequisites. In any case, assuming somebody needs to evaluate an alternate specialist organization, then, at that point Doitvision ought to be the decision. Despite the fact that we are new to this industry, one thing is without a doubt that our clients will leave with a major grin on their countenances. We offer an assortment of things like IP68 outside screens, innovative adaptable screens, Xr stage screens etc (What is a Xr stage). Along these lines, give choice in support of ourselves and assist us with getting into this rundown later on.