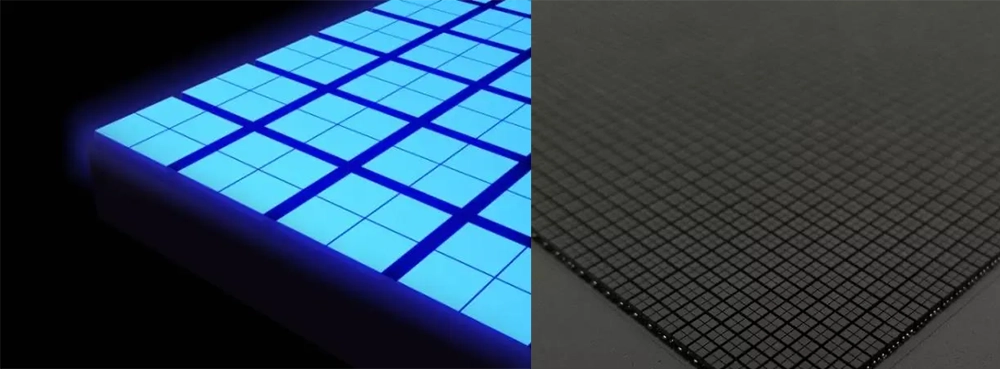

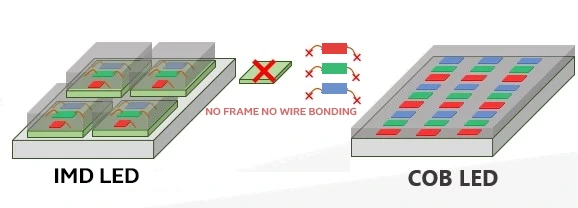

The technical definition of IMD

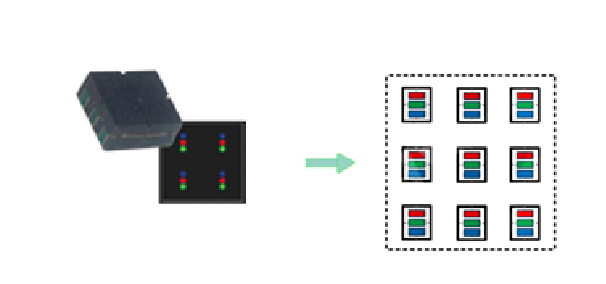

The matrix-integrated package scheme of IMD (Integrated Matrix Devices) is to package two, four, six, or more groups of RGB diodes in a small unit, also known as “N in 1”. A typical IMD model is produced in the form of 2*2, or 4-in-1. Each 4-in-1 package includes 4 SMDs; each SMD includes the three chips (Red, Green, and Blue). IMD is an intermediate product between SMD and COB and has the combined advantages of both. NationStar IMD09 is the major 4-in-1 model used in the market for the production of 0.9mm fine-pitch LED displays. It officially entered mass production in

Mini LED : 4 SMD Packed in one

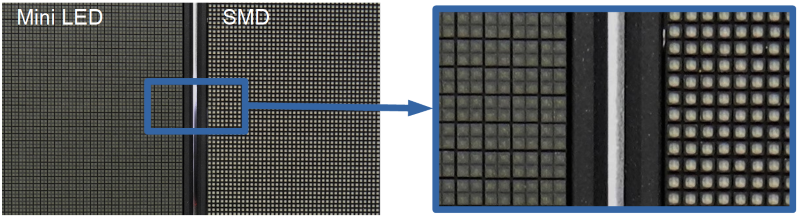

Figure 1: IMD Mini LED vs SMD

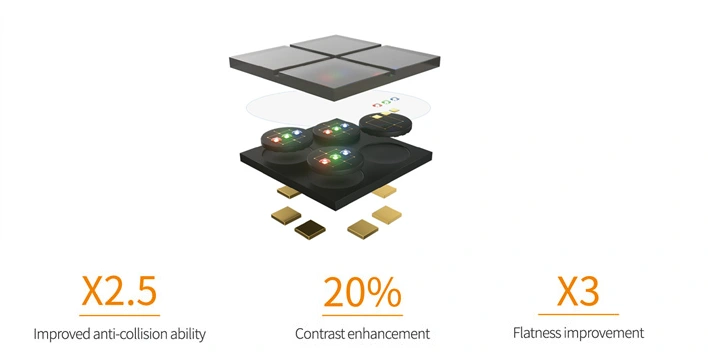

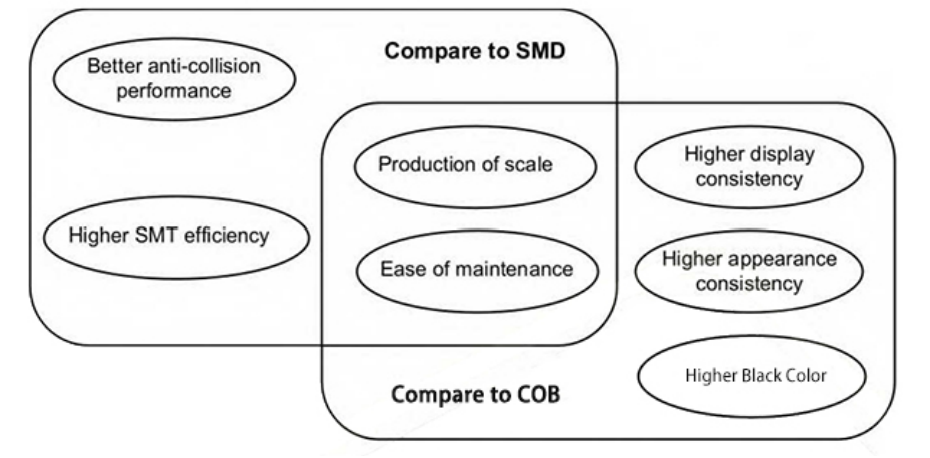

Figure 2: IMD mini LED vs COB

Advantages:

Higher reliability. Compared with traditional SMD, IMD has better anti-collision performance and higher SMT efficiency. Compared with COB.

Higher color consistency. IMD combines the advantages of traditional SMD and COB and has properly addressed issues in damage protection, black consistency, seamless splicing, light leakage

Lower maintenance costs, especially when there is only a single diode to be repaired. , and maintenance. It features a higher contrast ratio, higher integration, easier maintenance, and lower cost, which makes it an ideal product for the evolution of finer pitches.

Lower Manufacturing Cost. Traditional SMT 1010 machines can still be used for the production of IMD with a similar manufacturing process. By keeping the SMT process, LED display manufacturers can move to IMD display production faster, due to the existing mature SMT supply chain.

Disadvantages:

With the continuous narrowing of pixel pitch, IMD faces the same problem as SMD-there will always be a physical limit, leaving limited room for IMD product growth.

Without further subdivision of bins by chip suppliers, IMD’s bin-selection process becomes more difficult as it has multiple RGB chips per package. The uniformity and consistency of RGB chips in each package may not be as high as LED displays made of individual SMDs.

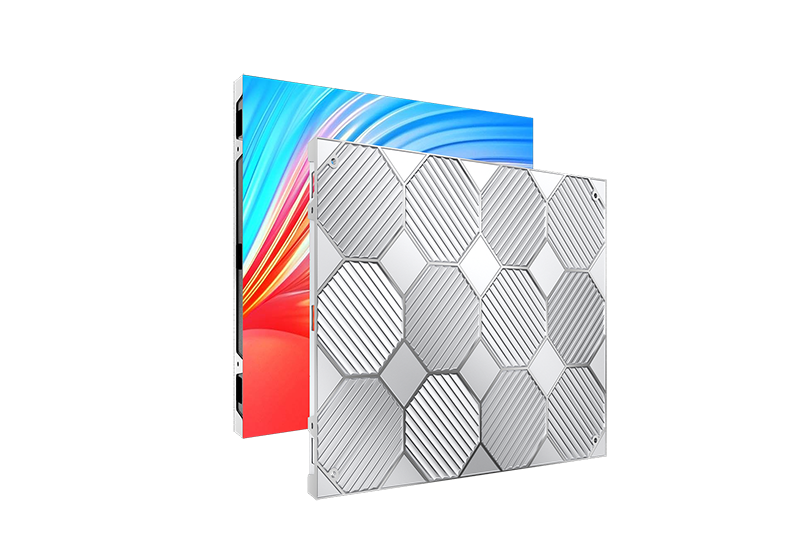

Mini LED Display: Fixed Installation

Dimension: 500*500*74.3mm

Pixel Pitch Indoor: Mini LED 1.95mm, 2.6mm

Applications: XR studios, TV stations, exhibitions,conferences, etc.

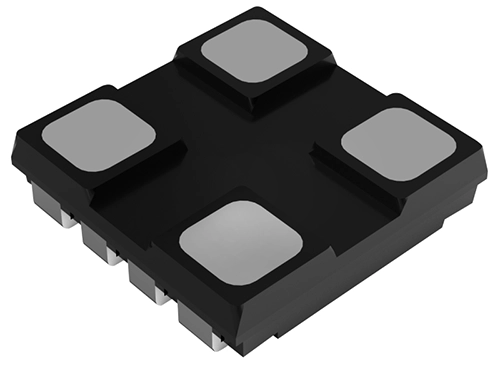

4 in 1 Mini LED

Mini LED Rental Display P1.9 2.6

Key Features:

● Unique Mini 4in1 LED,can bear 13kg impact force per pixel.

● High contrast ratio to 10000:1.

● Reduce more effect during camera shooting.

● High brightness up to 1500nits.

● High refreshment up to 7680Hz.

● Intelligent module.

Seriously!You made a number of nice points there. I did a search on the theme and found mainly folks will consent with your blog. This internet site may perhaps be the best I have seen in a while. Your post offers fantastic content material. Ive been looking everywhere for information for this kind of stuff. I looked everywhere, I looked in Yahoo, and I didnt find your posting right up until now. Honestly, you truly present good content, it is really useful. I will be returning here in the near future. Please keep your website current, it’s excellent. Go check out my site and buy a Nook

thanks!

Thanks for any other informative web site. Where else may I am getting that kind of information written in such a perfect approach? I have a undertaking that I am simply now working on, and I’ve been on the look out for such information.

What i don’t understood is in fact how you’re no longer actually a lot more well-appreciated than you may be now. You’re very intelligent. You understand thus significantly when it comes to this subject, made me for my part consider it from numerous varied angles. Its like men and women are not interested except it is something to accomplish with Woman gaga! Your personal stuffs excellent. At all times handle it up!

Everyone loves what you guys tend to be up too. This kind of clever work and reporting! Keep up the superb works guys I’ve added you guys to blogroll.

I?ve been exploring for a little for any high-quality articles or weblog posts in this kind of area . Exploring in Yahoo I ultimately stumbled upon this website. Studying this information So i am satisfied to convey that I have a very just right uncanny feeling I found out exactly what I needed. I most undoubtedly will make certain to don?t omit this site and give it a glance on a relentless basis.

Thanks for the suggestions you are revealing on this web site. Another thing I would really like to say is always that getting hold of some copies of your credit history in order to inspect accuracy of any detail will be the first activity you have to accomplish in repairing credit. You are looking to cleanse your credit reports from harmful details mistakes that ruin your credit score.

Hello, this weekend is good in favor of me, as this

time i am reading this great educational piece of writing here at my house.

I was very happy to search out this web-site.I wanted to thanks for your time for this wonderful learn!! I positively having fun with every little little bit of it and I’ve you bookmarked to check out new stuff you weblog post.

I would like to thank you for the efforts you’ve put in writing this blog. I’m hoping the same high-grade site post from you in the upcoming also. In fact your creative writing skills has inspired me to get my own blog now. Actually the blogging is spreading its wings quickly. Your write up is a good example of it.

I conceive you have remarked some very interesting details, appreciate it for the post.

A person essentially help to make seriously articles I would state. This is the first time I frequented your website page and thus far? I amazed with the research you made to create this particular publish extraordinary. Magnificent job!

It is really a nice and helpful piece of info. I?m glad that you shared this useful information with us. Please keep us up to date like this. Thank you for sharing.

I’m blown away by the quality of this content! The author has clearly put a huge amount of effort into researching and organizing the information. It’s inspiring to come across an article that not only gives useful information but also keeps the readers captivated from start to finish. Kudos to him for producing such a masterpiece!

Your webpage doesn’t display appropriately on my iphone – you may wanna try and repair that

I’ve been exploring for a bit for any high quality articles or blog posts on this sort of area . Exploring in Yahoo I at last stumbled upon this web site. Reading this info So i’m happy to convey that I have a very good uncanny feeling I discovered just what I needed. I most certainly will make sure to don’t forget this site and give it a glance regularly.

Have you ever considered writing an ebook or guest authoring on other sites? I have a blog centered on the same subjects you discuss and would love to have you share some stories/information. I know my audience would enjoy your work. If you’re even remotely interested, feel free to shoot me an e-mail.

Hello! Would you mind if I share your blog with my myspace group? There’s a lot of people that I think would really enjoy your content. Please let me know. Many thanks

It is best to participate in a contest for top-of-the-line blogs on the web. I will suggest this website!

I’m really inspired together with your writing skills as neatly as with the structure in your weblog. Is that this a paid subject or did you customize it yourself? Anyway keep up the excellent quality writing, it?s rare to see a great weblog like this one these days..

One other issue is that if you are in a scenario where you do not possess a co-signer then you may really want to try to exhaust all of your federal funding options. You will discover many funds and other scholarship grants that will ensure that you get funding to help you with college expenses. Thanks alot : ) for the post.

I’m extremely impressed with your writing skills and also with the layout on your blog. Is this a paid theme or did you modify it yourself? Anyway keep up the nice quality writing, it is rare to see a nice blog like this one nowadays..

Spot on with this write-up, I truly assume this website wants rather more consideration. I?ll in all probability be once more to learn far more, thanks for that info.

My brother recommended I may like this web site. He was once totally right. This publish actually made my day. You can not imagine just how a lot time I had spent for this information! Thank you!

I can’t believe how amazing this article is! The author has done a fantastic job of conveying the information in an compelling and informative manner. I can’t thank her enough for offering such valuable insights that have definitely enriched my understanding in this topic. Hats off to him for producing such a masterpiece!

Wow, fantastic blog layout! How long have you ever been blogging for? you make running a blog look easy. The overall look of your website is excellent, let alone the content!

F*ckin? tremendous things here. I?m very glad to peer your article. Thanks so much and i am taking a look ahead to touch you. Will you kindly drop me a mail?

Wow! This could be one particular of the most useful blogs We’ve ever arrive across on this subject. Basically Great. I’m also a specialist in this topic therefore I can understand your hard work.

hello there and thank you for your information ? I have certainly picked up anything new from right here. I did however expertise several technical points using this website, since I experienced to reload the site many times previous to I could get it to load correctly. I had been wondering if your web host is OK? Not that I am complaining, but sluggish loading instances times will often affect your placement in google and can damage your high quality score if advertising and marketing with Adwords. Well I?m adding this RSS to my e-mail and could look out for much more of your respective fascinating content. Make sure you update this again very soon..

Thanks for another great post. Where else could anyone get that type of info in such an ideal way of writing? I’ve a presentation next week, and I am on the look for such information.

Thanks for some other informative site. The place else may I get that type of info written in such an ideal method? I have a undertaking that I am simply now operating on, and I’ve been at the glance out for such information.

Some genuinely wonderful work on behalf of the owner of this web site, absolutely outstanding content.

Superb post however I was wanting to know if you could write a litte more on this subject? I’d be very grateful if you could elaborate a little bit more. Many thanks!

Hey there! I know this is somewhat off topic but I was wondering if you knew where I could find a captcha plugin for my comment form? I’m using the same blog platform as yours and I’m having trouble finding one? Thanks a lot!

Good day! This is my first visit to your blog! We

are a collection of volunteers and starting a

new initiative in a community in the same niche.

Your blog provided us beneficial information to work on. You have done a outstanding

job!

If you are going for most excellent contents like I do,

just pay a quick visit this site all the time as it provides quality

contents, thanks

Howdy! This is my first visit to your blog! We are a

collection of volunteers and starting a new project in a community in the same

niche. Your blog provided us valuable information to work on. You have done a

extraordinary job!

Having read this I thought it was very informative. I appreciate you taking the time and effort to put this article together. I once again find myself spending way to much time both reading and commenting. But so what, it was still worth it!

Yes! Finally someone writes about kontol.

Pretty section of content. I just stumbled upon your

web site and in accession capital to assert

that I get actually enjoyed account your blog posts. Anyway I’ll be subscribing to your feeds

and even I achievement you access consistently rapidly.

It’s going to be finish of mine day, except before end I am reading this great

piece of writing to improve my know-how.

At this moment I am going away to do my breakfast, when having my

breakfast coming again to read other news.

Hello to every one, the contents existing at this web site are truly awesome for people experience,

well, keep up the nice work fellows.

I’m really impressed together with your writing talents and

also with the layout to your blog. Is that this a paid topic or did you customize it your self?

Either way stay up the nice high quality writing, it is rare to peer a nice blog like this one nowadays..

Very good information. Lucky me I ran across your blog by accident (stumbleupon).

I have book-marked it for later!

Thank you for the auspicious writeup. It in truth was once a entertainment account

it. Look complex to more brought agreeable from you!

By the way, how could we be in contact?

If you are going for most excellent contents like I do, simply pay a quick visit this web site

daily since it presents quality contents, thanks

Wow, that’s what I was looking for, what a information! present

here at this web site, thanks admin of this website.

Do you have any video of that? I’d love to find out some additional information.

Appreciating the commitment you put into your website and detailed information you present.

It’s nice to come across a blog every once in a while

that isn’t the same unwanted rehashed information. Great read!

I’ve bookmarked your site and I’m adding your RSS feeds to my Google account.

If you are going for most excellent contents like I do, only go to see this web site all the time since it presents quality contents, thanks

Terrific work! This is the type of information that

should be shared across the web. Disgrace on Google for not positioning this put up higher!

Come on over and talk over with my web site . Thanks =)

I?m not sure where you’re getting your info, but good topic. I needs to spend some time learning much more or understanding more. Thanks for excellent information I was looking for this information for my mission.

Avrupa’nın en güvenilir medyum hocalarından medyum haluk yıldız hocamız siz değerli kardeşlerimize yardım eli uzatıyor.

I read this article fully concerning the comparison of newest and

preceding technologies, it’s amazing article.

Hey! I’m at work surfing around your blog from my new iphone! Just wanted to say I love reading through your blog and look forward to all your posts! Carry on the outstanding work!

My brother suggested I might like this web site. He was totally right.

This post actually made my day. You cann’t imagine simply how much time

I had spent for this info! Thanks!

I really appreciate this post. I have been looking all over for this! Thank goodness I found it on Bing. You’ve made my day! Thanks again

I do not even know the way I ended up here,

however I assumed this put up was once great. I don’t recognize who you’re however

definitely you’re going to a well-known blogger in case you are not already.

Cheers!

Exceptional post but I was wanting to know if you could write a litte more on this topic? I’d be very thankful if you could elaborate a little bit more. Kudos!

Fantastic items from you, man. I have have in mind your stuff previous to and you are just too great. I actually like what you’ve acquired right here, really like what you are stating and the way during which you are saying it. You make it entertaining and you still take care of to stay it wise. I can not wait to read far more from you. This is actually a tremendous site.

WONDERFUL Post.thanks for share..more wait .. ?

There is certainly a lot to find out about this subject. I like all of the points you’ve made.

Excellent post. I am dealing with some of these issues as well..

I?m not sure where you’re getting your information, but great topic. I needs to spend some time learning more or understanding more. Thanks for wonderful information I was looking for this info for my mission.

I blog often and I really thank you for your information. The article has truly peaked my interest. I will take a note of your blog and keep checking for new information about once per week. I subscribed to your RSS feed too.

I think this is one of the most important information for me.

And i am glad reading your article. But want to remark on some

general things, The website style is perfect, the articles is really great :

D. Good job, cheers

Hey very interesting blog!

Right here is the perfect site for anybody who would like to understand this topic. You realize a whole lot its almost tough to argue with you (not that I personally would want to…HaHa). You certainly put a brand new spin on a topic that has been discussed for a long time. Excellent stuff, just excellent.

It’s difficult to find educated people about this topic, but you sound like you know what you’re talking about! Thanks