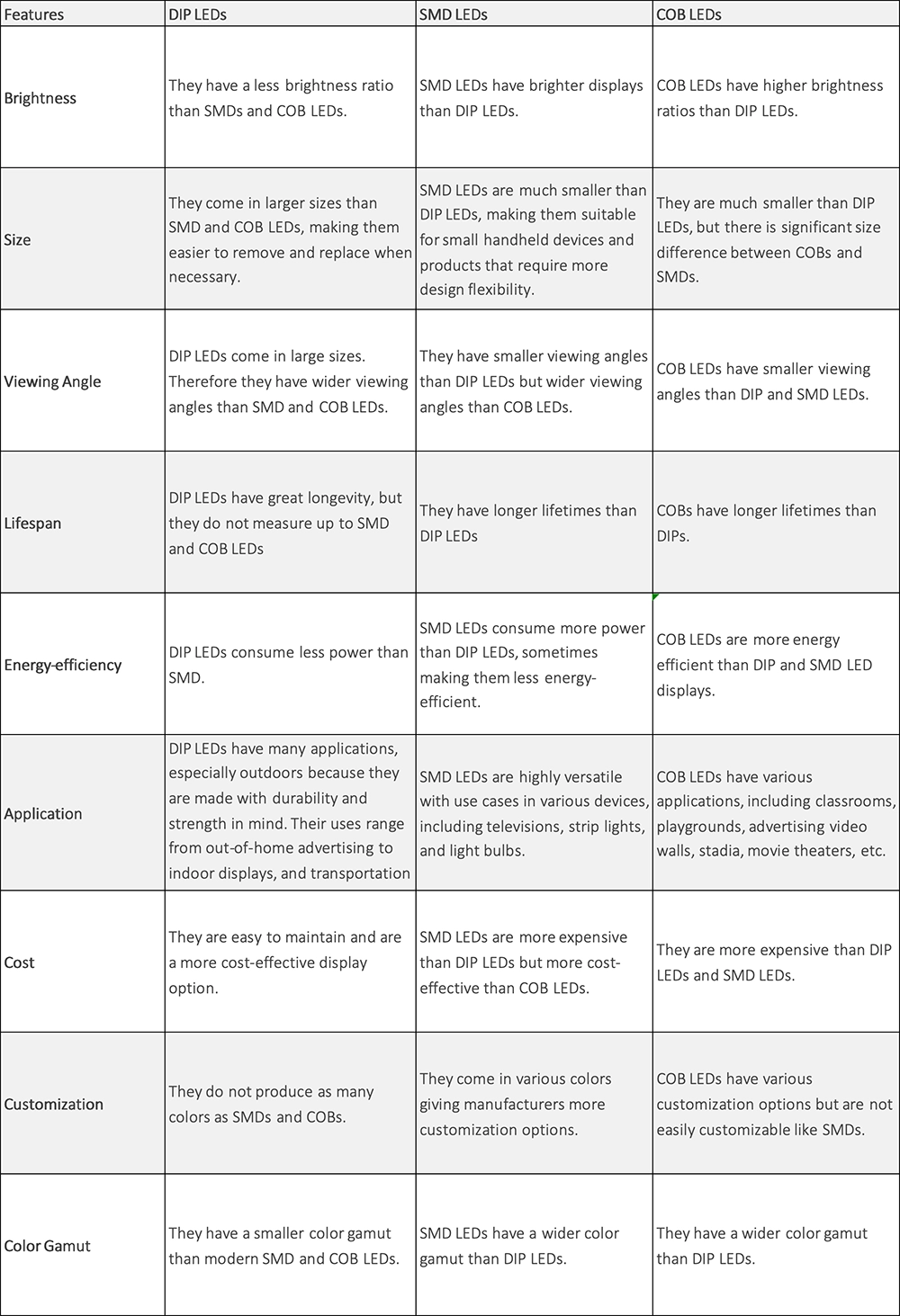

DIP (Dual In-Line Package) LEDs have long been the preferred choice for LED advertising screens due to their high resistance to outdoor environments and impressive luminosity, making them an ideal choice. However, their usage has shifted recently, with DIP LEDs now primarily employed in specific projects that demand a high degree of impact resistance. Despite lower production volumes compared to other LED technologies, which makes them more expensive, their performance and exceptional durability keep them competitive in the market.

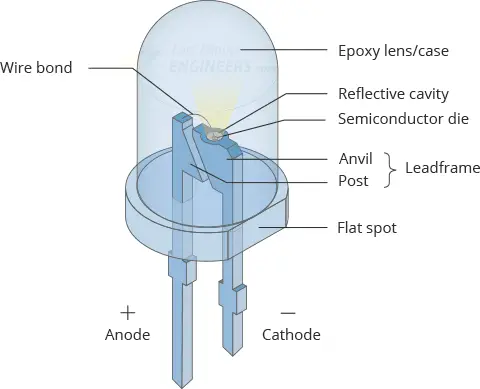

One standout feature of DIP LEDs is their robust resistance to impacts and blows, largely attributable to their generous resin encapsulation that covers the exterior thoroughly. Additionally, DIP LEDs are integrated into modules or LED plates by soldering two pins directly onto the circuit board. This method of connection provides a more durable bond than other systems, such as those used in SMD LEDs, offering superior resistance and longevity.

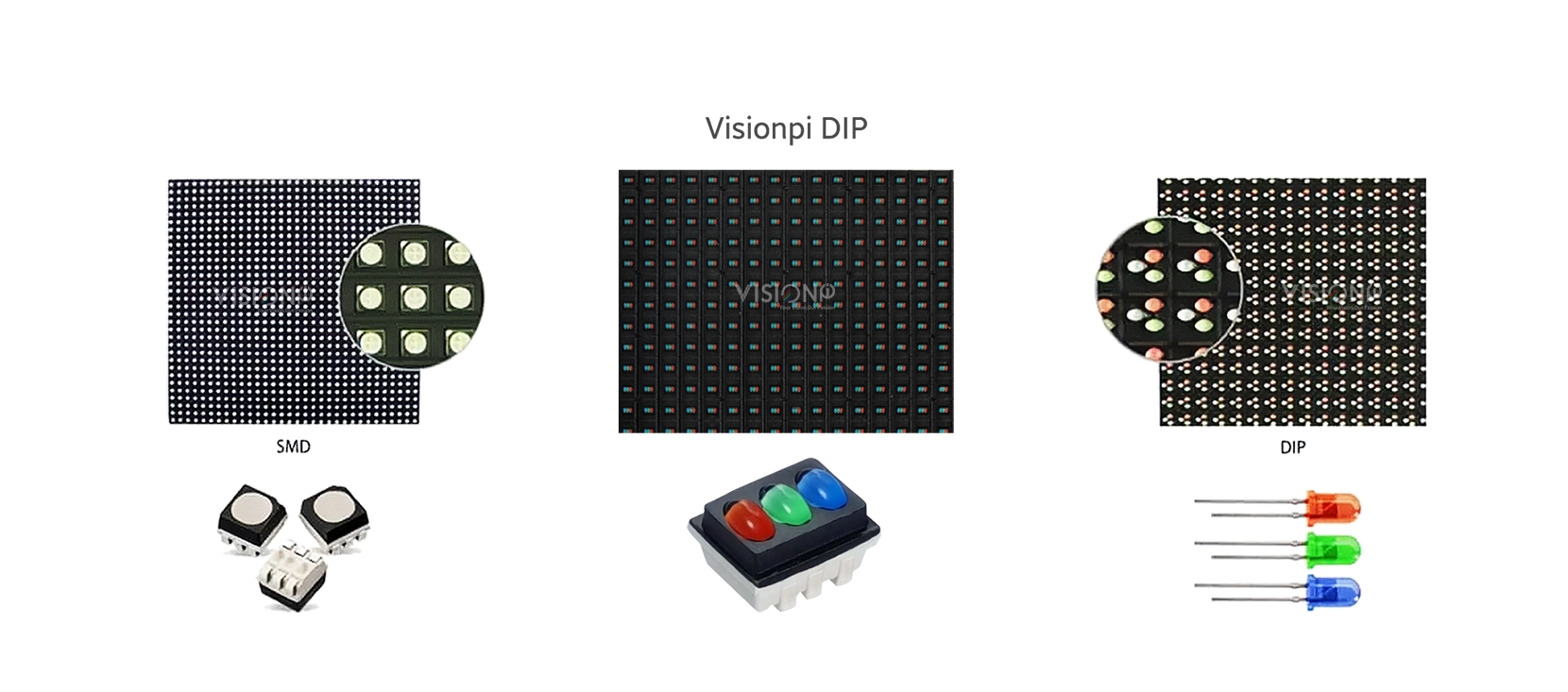

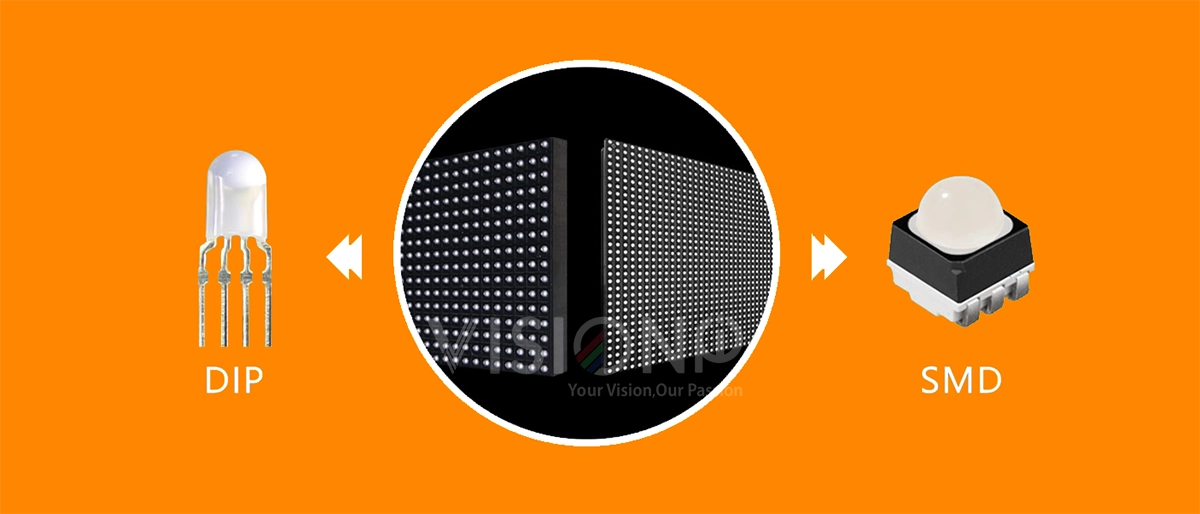

Many LED display manufacturers have focused on developing SMD business but neglected the production and development of DIP. This is a mistake, as the market needs both types of products. VISIONPI is one of the few manufacturers that can provide high-quality and reliable products in both SMD and DIP fields.

Customized SMD4535 lamp beads feature patented epoxy resin elliptical lenses with colored transparent MOLD packaging, offering high brightness, superior weather and UV resistance, and excellent waterproof performance. These lamp beads combine the efficiency of surface mount technology with the durability of direct insertion lamps, addressing the waterproofing challenges of traditional SMDs.

What is DIP LED:

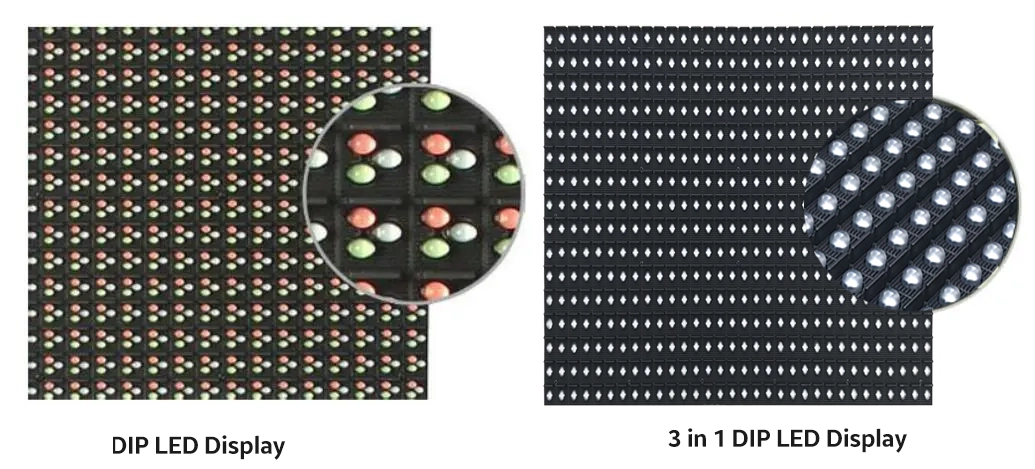

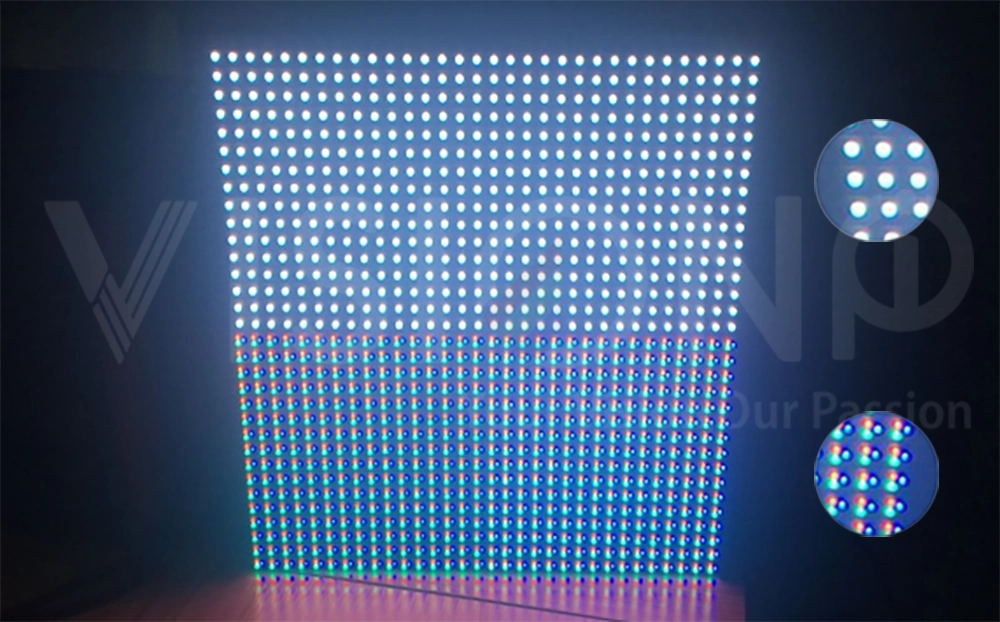

DIP technology is a type of LED display that uses dual in-line package LEDs, which are electronic components with two rows of pins that connect to a circuit board. DIP displays have three separate LEDs for each pixel, one for red, one for green, and one for blue. This allows them to produce bright and vivid colors, especially for outdoor applications.

Advantages of DIP LED Display

- Durability and strength: DIP LED display is made of sturdy and high-quality materials, which can withstand harsh weather conditions, such as rain, wind, or dust. It can maintain its lifetime and resolution for a long time.

- Direct insertion led display light: it is a type of light that has one colour chip inside. It uses red, green and blue lights to make different colours. Each light has a long wire that makes it very bright outside. It does not need a lot of electricity or get very hot. Each light is separate from the others and lasts for a long time.

- Welding method: it is a way of connecting the lights to a board. It makes the lights stick to the board very well. It does not have problems with loose wires or bad connections. It works well outside where the weather is rough. It does not need a lot of repairs or cost a lot of money. It makes the display look good and work well.

- Sealing method: it is a way of protecting the lights and the board from water and other things. It uses a material called silicone that covers the lights and the board. It is thicker than the usual material and costs more. But it is better at keeping the water, moisture and sun away from the lights and the board.

- Direct insertion led display compared to table sticker products: it is a type of display that has better quality, brightness and efficiency. It is good for seeing from far away. It is the best choice for places that need a special display that is bright and clear

- High brightness: DIP LED display can produce bright and vivid colors, even under sunlight or other bright environments. It can reach up to 10,000 nits, which is much higher than other display technologies.

- Lower power consumption: DIP LED display is more energy-efficient than other display technologies, such as LCD or SMD. It can save up to 1/3 of the power, which can reduce the cost and environmental impact.

- Color uniformity: DIP LED display can ensure that the colors on the screen are consistent, vibrant, and similar to the source, without any distortion or fading.

- Wide viewing angle: DIP LED display can provide consistent and uniform display quality across different angles, ensuring that the audience can see the content clearly from any direction.

- Easy maintenance: DIP LED display is easy to repair and replace, as each LED module can be removed and replaced individually, reducing downtime and cost.

- Longer lifetime: DIP LED display can last longer than other display technologies, as it has lower heat dissipation levels, which can prevent the LED modules from overheating and damaging.

Application of DIP LED Display

-

Currently, DIP LEDs are used in situations where durability and strength, as well as brightness intensity, are key factors. For years, they have been the most used type of LED in all types of applications. This situation is changing recently, due to the rise of the more advanced SMD LEDs.

In addition, the market for LED screens keeps demanding higher screen resolutions, which can only be achieved through the use of SMD leds with smaller pixels. However, DIP technology LED screens are still a great product, suited for screens that will be viewed at great distances, thanks to their brightness with a high durability and resistance.

Energy-saving 3 in 1 DIP LED Display

– Innovative Technology: Features patented, custom energy-saving ICs and “three colors in one” lamp beads.

– High Brightness: Delivers exceptional luminosity ranging from 8000-10000 nits.

– Low Power Consumption: Operates at an average power consumption of only 100W/m², achieving energy savings of 40%-50%.

– Advanced Beads: Independently developed in-line “three-color in one” lamp beads enhance color mixing.

Durability and Reliability

– Proven Track Record: 30 years of market presence with rigorous quality control from the outset.

– Robust Packaging: Utilizes DIP570 packaging technology with independent packaging.

– Comprehensive Inspections: Full inspection before shipment, including five preventative checks such as aging and resistance to water, ensuring exceptional performance in harsh environments.