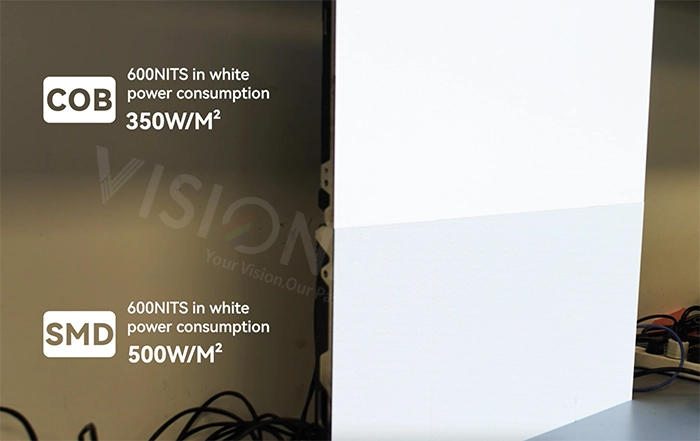

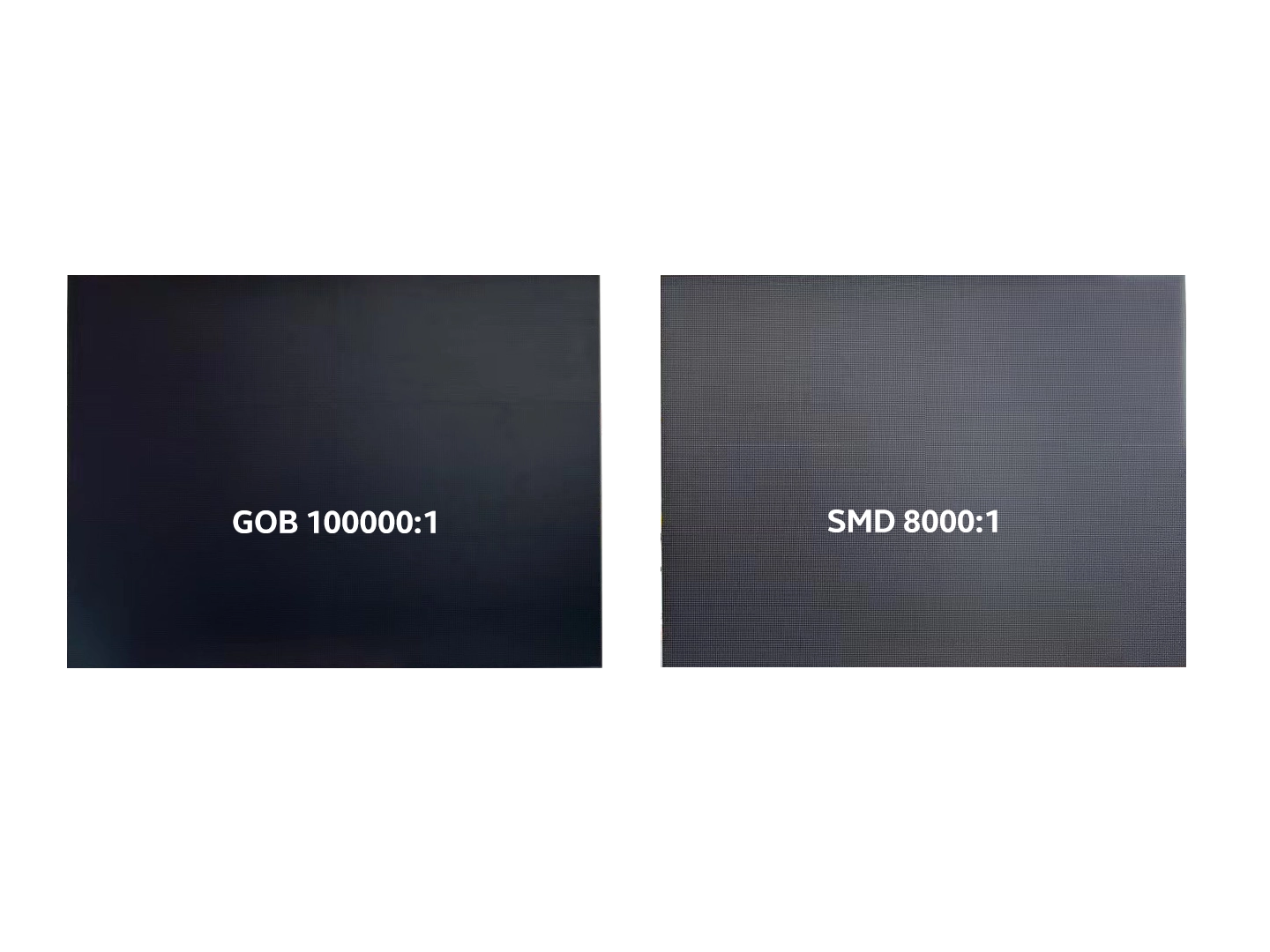

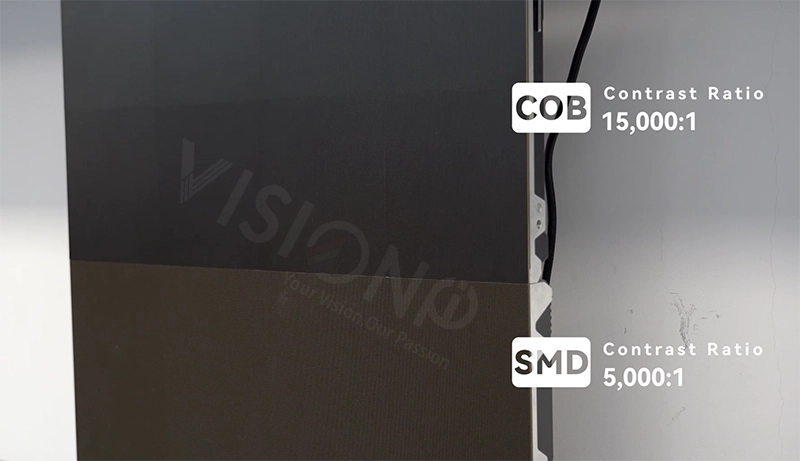

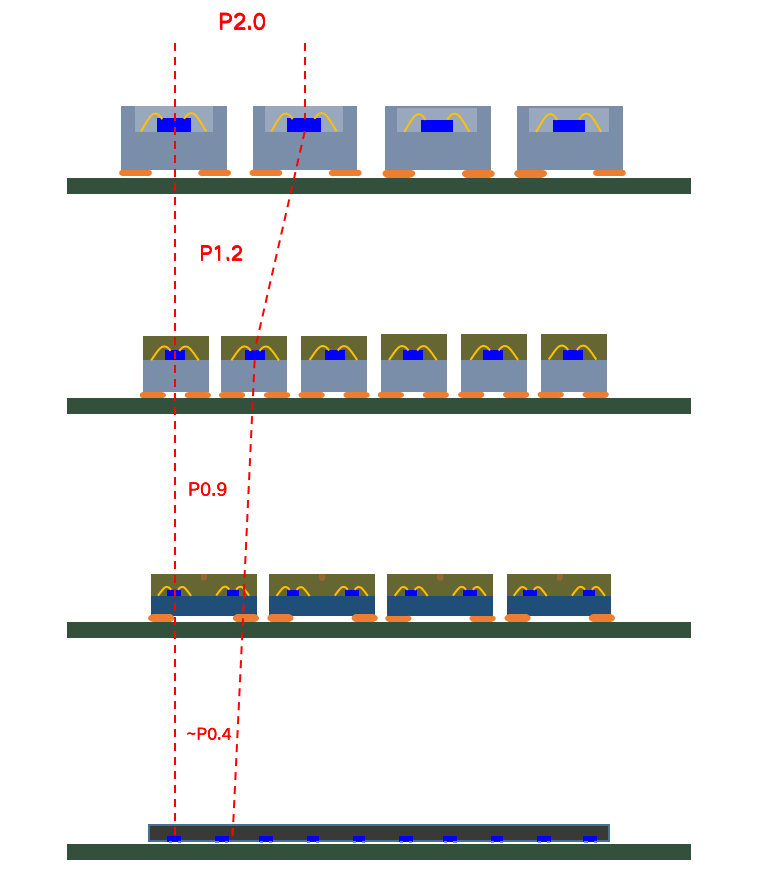

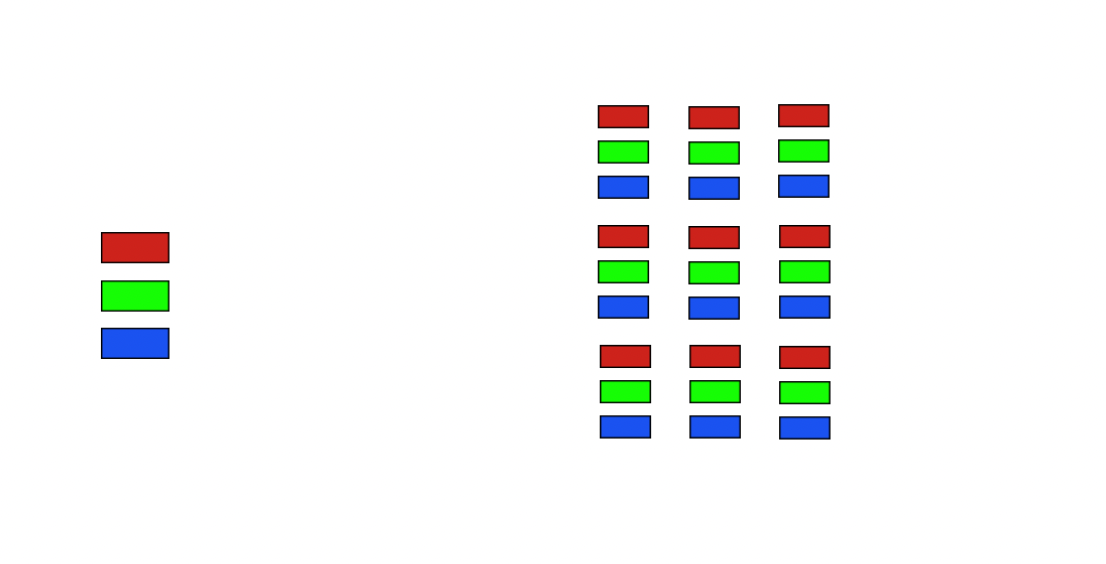

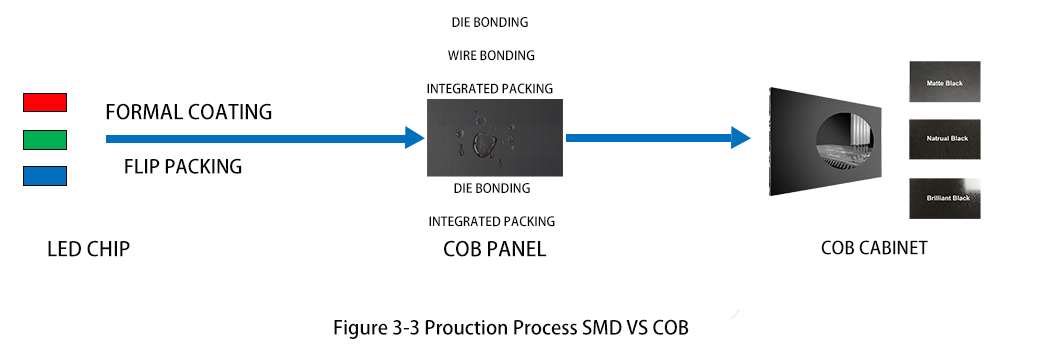

In the field of LED display, with the development of upstream packaging technology, there gradually form two different LED display panel preparation technologies, SMD ;IMD; COB. We can use these two technologies to produce small-spacing mini LED display screens. And we will share some information about these two technologies with you.

What is COB?

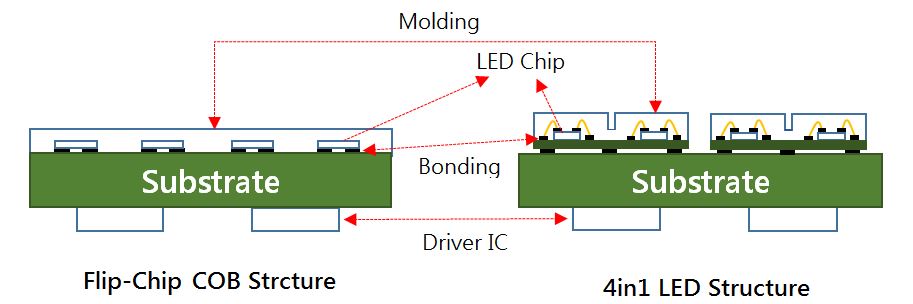

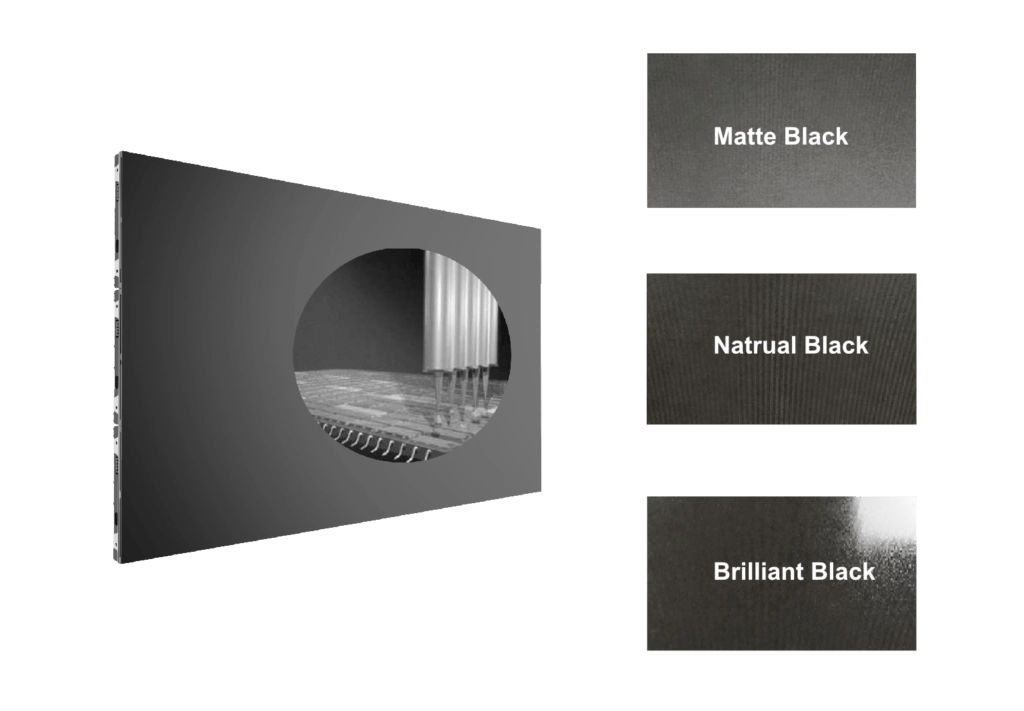

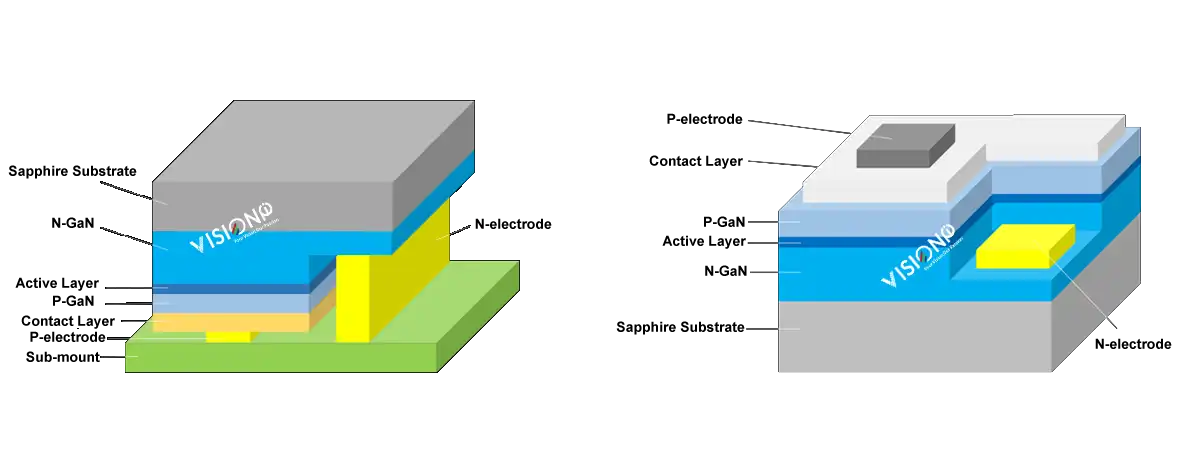

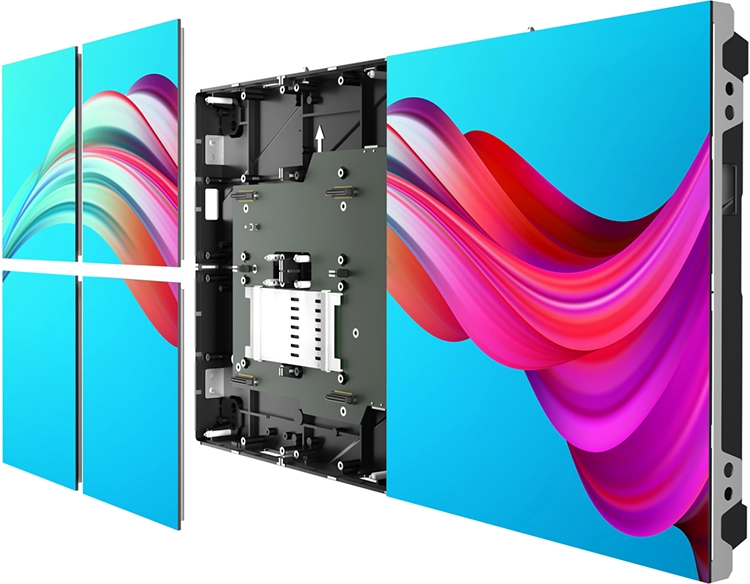

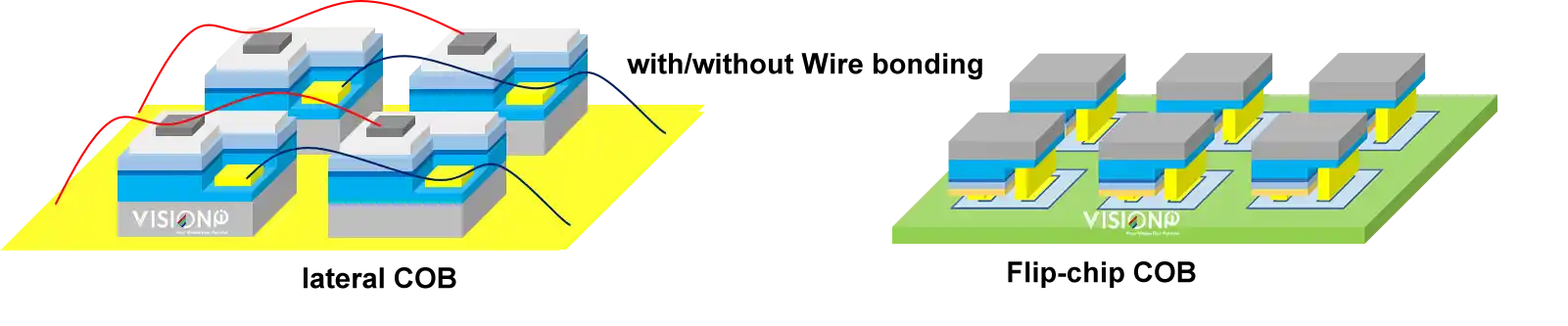

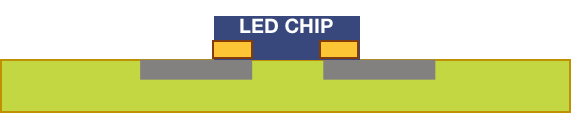

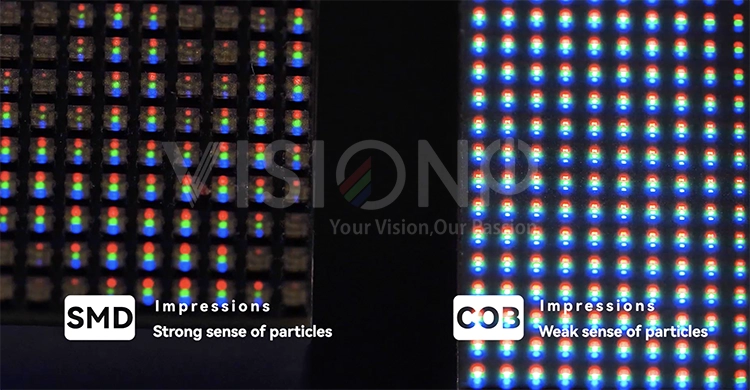

COB (Chip on Board) is a kind of LED display packaging technology. LED light-emitting chips are directly bonded to the module board with high precision and connected to driver components on the module board through special media for overall protection of the light-emitting surface. COB packaging eliminates the two key procedures of turning LED chips into lamp beads and reflow soldering as compared to standard SMD packaging.

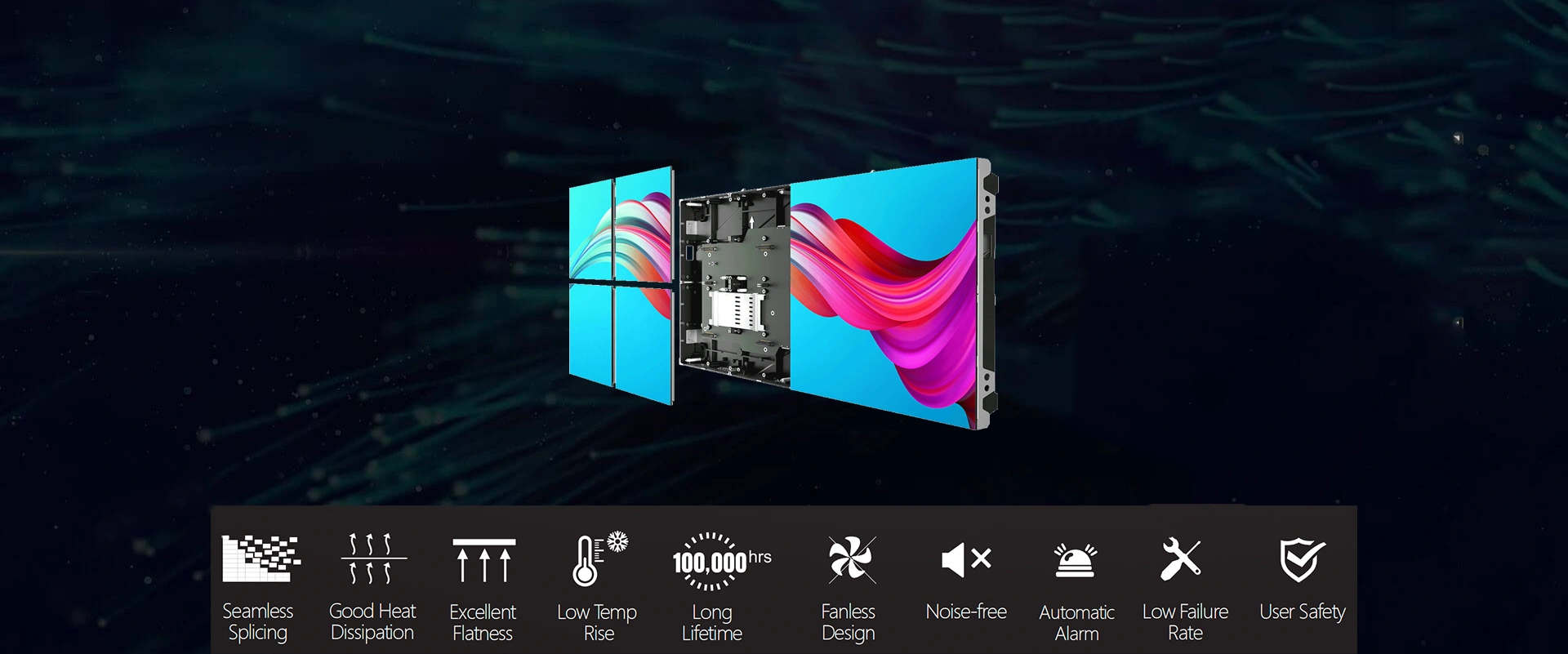

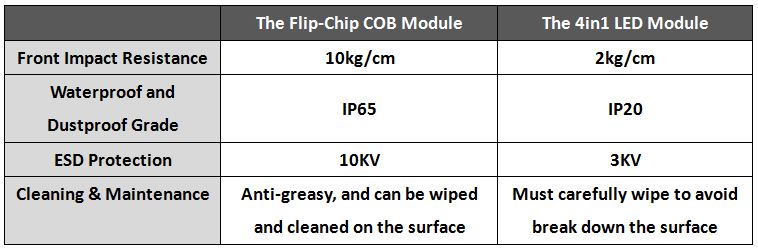

Superior Durability COB is better at withstanding collisions and the effects of Oil, Damp, Water, Dust, Oxidisation, and dust.

Superior Durability COB is better at withstanding collisions and the effects of Oil, Damp, Water, Dust, Oxidisation, and dust.